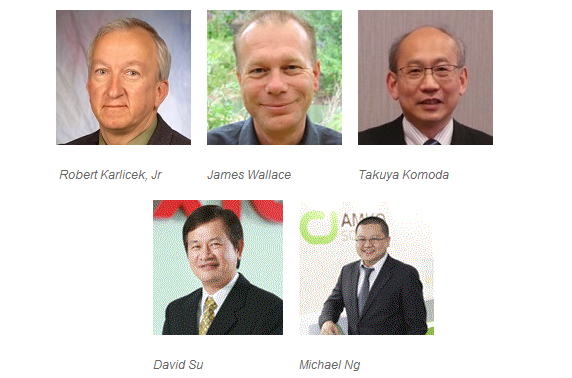

The SSL industry has seen substantial growth recently that is only to increase over the next few years. During the Taiwan Solid State Lighting forum at Taiwan International Lighting Show (TILS) 2014 on March 20th, industry experts shared their insight on the direction the SSL industry will take in the future. Panelists discussing the future development and challenges of SSL included Rensselaer Polytechnic Institute Director and Professor Robert Karlicek, Jr, lighting designer and Director of Professional Lighting Designers’ Association James Wallace, Research Director for Panasonic Takuya Komoda, Chairman of Lextar Electronics David Su, and Vice Chairperson of International Affairs Committee Michael Ng.

Q. What will be the next phase of development of LED?

Robert Karlicek, Jr: Phosphor converted LEDs are about as efficient as it will ever get. There are certain improvements with package design and secondary optics, but the fundamental technical evolution of the white phosphor converted LED is essentially reaching its technological limits. So the next steps of evolution for the LED is to start to take a look at the ability to generate other colors simultaneously for color tuning.

More and more LED manufacturers are starting to look carefully at how to build either phosphor converted saturated color light emitted diodes or direct emitters with higher efficiency. Governments are now starting to invest more money into how to create more efficient green or more efficient yellow light emitting diodes. Red LEDs and blue LEDs are at the limits of their technological evolution. One direction is going to be to be able to make LEDs at all wavelengths.

Another area where there is development with LEDs is how it is packaged. People are now developing brand new ways of packaging light emitting diodes, putting them on flexible surfaces, embedding them in waveguides, and putting them into fabric which is dropping the cost of the packaging. New technologies are going to make the LEDs very cheap and economical.

David Su: There is still a lot of development in the LED market that manufacturers can do. I believe it will be in two areas, retrofit and creative lighting. For the retrofit area, LEDs will replace existing traditional lighting. Manufacturers are mainly trying to reduce costs. I believe there are many solutions that can be implemented to lower cost. For manufacturers, we want to move towards more integration. We want to integrate LED chips, soluble solution, and drivers into one light engine. For creative lighting, I believe this is an area that is quite different from traditional lighting because SSL is a low voltage device that can be interfaced with many different functions, such as digital functions. Chip-scale package is another area that can develop for future products.

Q. What will be the next phase of development of OLED?

Takuya Komoda: Efficacy is still less than the LED and it is necessary to raise the level. The theoretical limit of the efficacy is almost the same as LED. OLED can achieve over 350 lumens per watt. I think that reaching 70 percent of the theoretical limit to 200 lumen per watt for OLED panel is possible is possible within three years. In order to achieve this, it is necessary to have more sophisticated lighting technology and devise structure.

David Su: From the application point of view, if you compare LED and OLED in terms of their market position, I feel they are in different sectors and are more complimentary with each other. LED is a point source which can be designed into a linear light source or area light source. OLED is an area light source. So it is difficult for area light source to get into a small light point source. I believe the future direction of OLED is in area light source and compliment with LED’s point light source. LED and OLED are not competitive, but rather complimentary technologies.

In terms of technology, lifetime cost is still a struggle for manufacturers. Compared with LED, technology and manufacturing capabilities still need to be set up for OLED. For LED, equipment and infrastructure is already present but for OLED, it is still in the research phase. You need to have a good equipment supplier and material supply chain to support the OLED industry for it to remain strong.

Industry Experts Weight in on LED and OLED Future Development (Part 1)

(Author: Leah Allen, Editor/Translator, LEDinside)