As LED’s penetration in the lighting industry increases, it is clear that enabling slimmer fixtures is an important area of market differentiation, an area where Samsung Lens-attached LED modules deliver the most efficient, homogeneous design solutions in LED lighting. It is now mass-producing a value-added line-up of highly efficient LAM, for use in office LED lighting applications that include linear and line lighting, cove lighting and troffers.

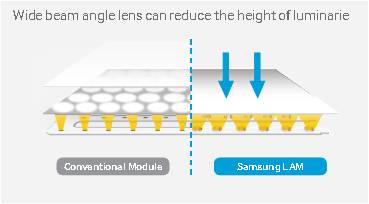

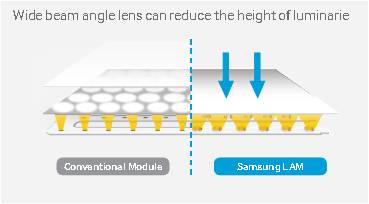

The LAM series is created by attaching lenses on top of the LED packages in each module. The lenses add wide beam angles for their light sources using advanced optic technology, so that each LED package can brighten a space larger than that of conventional packages.

|

|

LAM series LED module. (Samsung/LEDinside) |

Unlike fluorescent and incandescent lamps, conventional LED lighting features individual LED packages, each of which emits light. As a result, depending on the distance between the diffusion plate and the LED modules in the fixture, the spaces between packages on the module can appear as dark spots.

To prevent this, the diffusion plate has to be placed further away from the module, which unfortunately increases the thickness of the fixture. In contrast, LAM solution enables slim luminaire design. The diffusion plate can be placed much closer to the module using LAM’s diffusion-improving optic technology – as close as 45 millimeters, a significantly smaller space than the 80 to 100 millimeters needed for conventional T5/T8 fluorescent tubes.

|

|

Height comparison between conventional modules and Samsung LAM. (Samsung/LEDinside) |

The LAM-32B and LAM-30B feature high efficacy and high lumen output performance with better uniformity. Both LAM-32B and LAM-30B offer a range of correlated color temperature (CCT) – from 3000K to 6500K.

For more information, please visit the Samsung Electronics LED website : www.samsungled.com