|

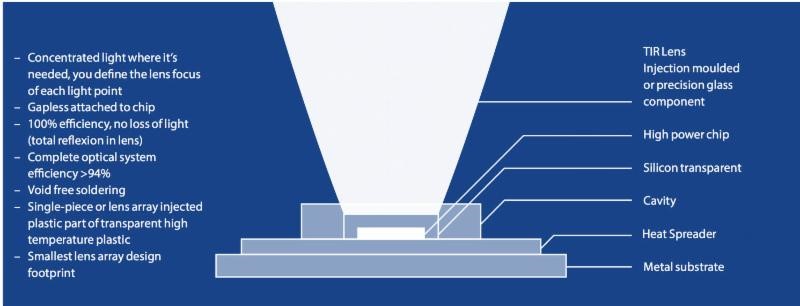

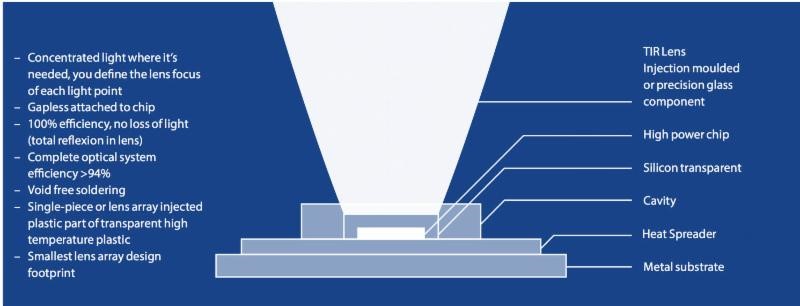

ESCATEC's Heat Spreader solution positions LEDs onto a copper substrate which dissipates heat ten times faster than existing solutions. (ESCATEC/LEDinside)

|

ESCATEC, one of Europe's leading providers of contract design and manufacturing services, will be launching its solution to the challenge of effectively cooling high brightness LEDs on its stand E8 at the LED Professional Symposium 2015 in Bregenz, Austria on 22-24 September 2015. http://www.led-professional-symposium.com

ESCATEC's Heat Spreader solution solders the LEDs onto a copper substrate, which is up to ten times more effective at dissipating the heat generated by the LEDs than current solutions. The CoolRunning design means that LEDs with a power density of up to 10W per mm2 could be passively cooled.

The Heat Spreader was developed in response to a customer visit to ESCATEC's FutureLab where novel and innovative solutions are developed for LED applications. "Heat dissipation is always a challenge for LEDs as their compact size means that the LEDs can be packed close together to form a powerful illumination source but that also forms a highly concentrated heat source, for example, when a hundred 5 Amp LEDs are side by side," explained Wolfgang Plank, Manager of the FutureLab. "Our novel Heat Spreader solution opens up compact, high power LEDs of, say 1000W, to be used in many new applications such as stage lighting, architectural illumination and video projectors."

By starting from the bare LED die, ESCATEC can customise the solution with regards to the size of the package, the shape of the beam so that there are minimal losses, and the wavelength of the light along with its intensity. This freedom of design enables the LED solution to be highly efficient, appropriately cooled and optimised for the required power consumption. It also enables the lens or lens array to be custom made to provide the exact optics required by the application and ensures that design can be compact with high optical efficiency.