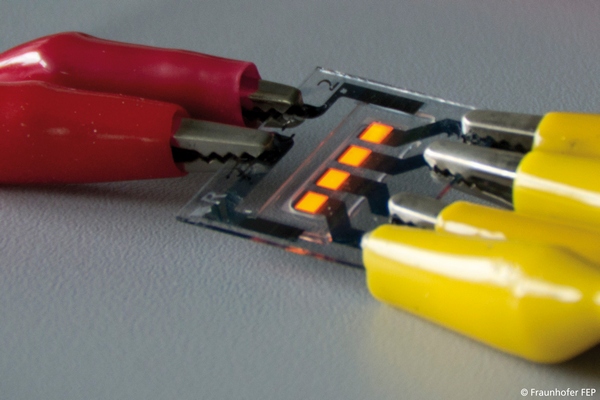

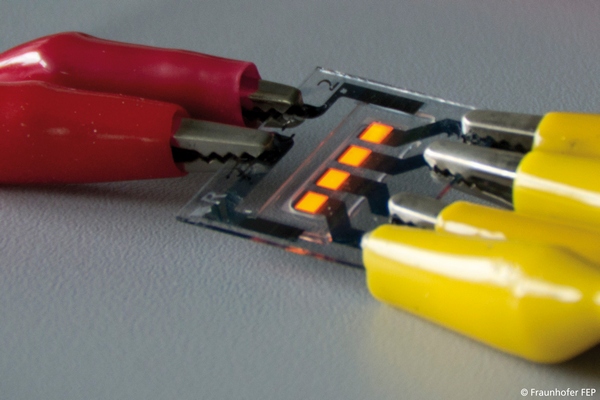

The Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP will show for the first time organic light emitting diodes (OLEDs) on graphene at Plastic Electronics 2015 (6th − 8th of October 2015, fair area Dresden, booth 1549, joint booth of OES – Organic Electronic Saxony). These OLEDs are an interim result from the project GLADIATOR funded by the European Commission.

The project GLADIATOR, which is funded by the European Commission, has reached its midterm and has already achieved some successes. The aim of the project is the cost-effective production of high quality graphene at large area, which can then be used for numerous electrode applications. The usability of such applications will be demonstrated at the Fraunhofer FEP by integrating this graphene in OLEDs.

|

|

Until now transparent electrode materials for OLEDs have mainly consisted of indium tin oxide (ITO), which is expected to become economically challenging for the industry due to the shrinking abundance of indium. Therefore, scientists are intensively looking for alternatives. One promising candidate is graphene, whose application fields are more closely investigated in the project GLADIATOR („Graphene Layers: Production, Characterization and Integration“. Photo courtesy of Fraunhofer Institute for Organic Electronics). |

With graphene as an electrode, the researchers at the Fraunhofer FEP hope for flexible devices with higher stability. Beatrice Beyer, project coordinator, says: “Graphene is a very interesting material with many possibilities. Because of its opto-electrical properties and its excellent mechanical stability, we expect that the reliability of flexible electronics will be improved many times over.”

Graphene is a rediscovered modification of carbon with two-dimensional structure, which has gained enormously in popularity since its successful isolation in 2004. Such so-called “monolayer” graphene is synthesized on a metal catalyst via a chemical vapour deposition (CVD) process and transferred by a further process step to a target substrate, such as thin glass or plastic film. Here, it is very important that no defects are added which might reduce the quality of the electrode. In order to compete with the reference material ITO, the transparency and conductivity of graphene must be very high. Therefore, not only the process of electrode manufacturing is being optimized, but also different ways of doping graphene to improve its properties are being examined.

At the same time, the developed process steps must be easily scalable for later industrial use. These many challenges are faced by a highly innovative and committed project consortium consisting of sixteen partners from six EU member states and Switzerland.

The Fraunhofer FEP is coordinating the GLADIATOR project and acts as an end-user of the graphene electrode. Scientists examine the integration of graphene and compare it to the reference material ITO. The sophisticated material properties of graphene must be maintained during the integration in organic devices. To this end, several methods for cleaning and structuring the graphene must be modified. In addition, the processes for different target substrates such as glass or flexible foil must be adapted and optimized. The first hurdles have been overcome thanks to a close cooperation between the consortium partners and the first defect-free OLEDs on transparent graphene electrodes have been realized on small areas. The target of the next one and a half years is to successfully illuminate large area OLEDs.

The GLADIATOR project will run until April 2017. By this time several types of OLED will have been made using graphene electrodes: a white OLED with an area of about 42 (cm)2 to demonstrate the high conductivity, and a fully-flexible, transparent OLED with an area of 3 (cm)2 to confirm the mechanical reliability.