Heavyweights in durability, yet sleek in design, MaxLite’s new series of LED Hazardous Location fixtures is designed to meet the challenges of lighting environments where safety and efficiency matter most.

|

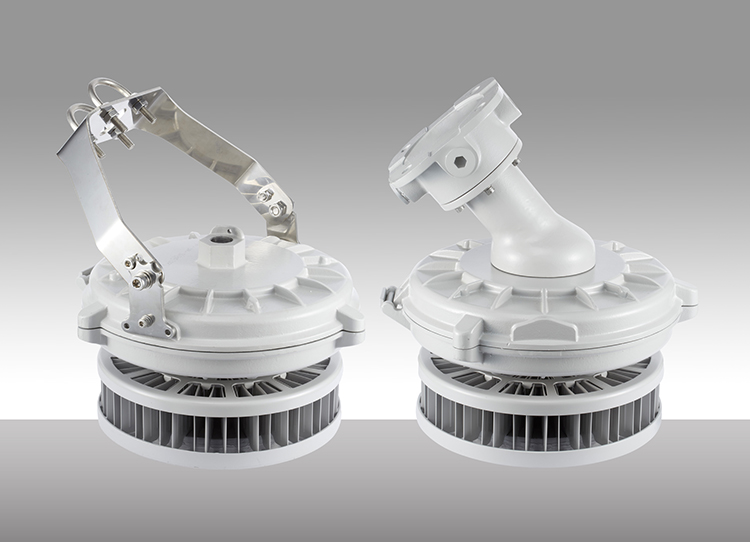

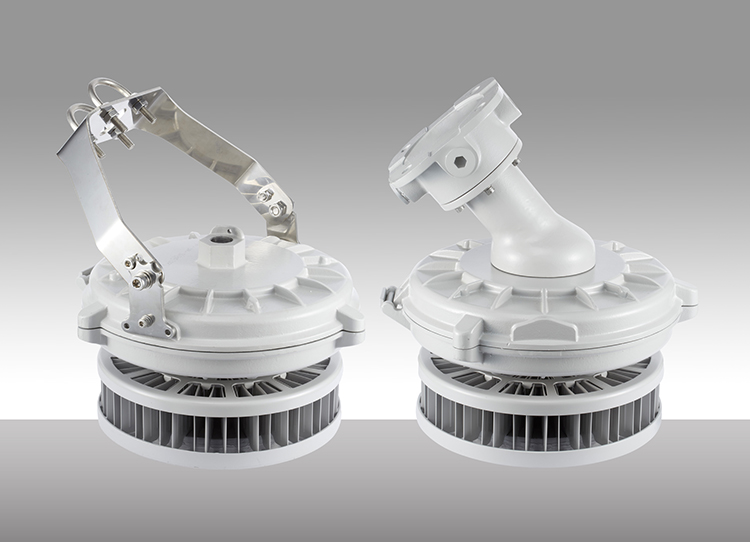

MaxLite unveils the new HLR sereis LED luminaires for outdoor hazardous applications. (MaxLite/LEDinside)

|

MaxLite HLR Series luminaires are certified for use in a wide range of indoor and outdoor hazardous areas, including those classified as Class I, Division 2 and Class II, Division 2. The LED luminaires lower energy consumption by more than 50 percent and operate twice as long as conventional HID fixtures, providing facilities such as oil platforms, mills and chemical plants with years of maintenance-free illumination and operational cost savings.

Performing at an exceptional 105 lumens per watt, the fixtures are available in an output range of 8,000 to 17,000 lumens to replace HID fixtures of up to 400 watts. They deliver crisp, bright light in 5000K with excellent color rendering, for optimal visibility.

“The demand for explosion-proof lighting continues to grow, and LED offers a tremendous upside for industrial facilities looking to replace older lighting systems,” said Associate Product Manager Amro El-Adle. “Our new HLR Series LED luminaires are more compact than incumbent light sources and operate at a much lower cost, providing operators with a quick return on their investment and significant long-term savings.”

A full range of mounting accessories is available to ease installation of the fixtures in ceiling, pendant, wall or surface applications. Built to resist corrosion, vibration, moisture and dirt, HLR Series fixtures are constructed of a durable die cast aluminum housing and full module heat sink that ensure reliable performance and longevity. The fixtures operate on 120-277V and 347-480V inputs, and feature integral 15kV surge suppression protection. Temperature class ratings vary by power level, with some models certified for use in T5 environments.