Panasonic Corporation announced that it has developed connectors for connecting in-vehicle LED lamp modules to control boards. These connectors improve in designing in-vehicle LED lighting.

|

Panasonic's newly-launched connectors enables connection between in-vehicle LED lamp modules to control boards. (Panasonic/LEDinside)

|

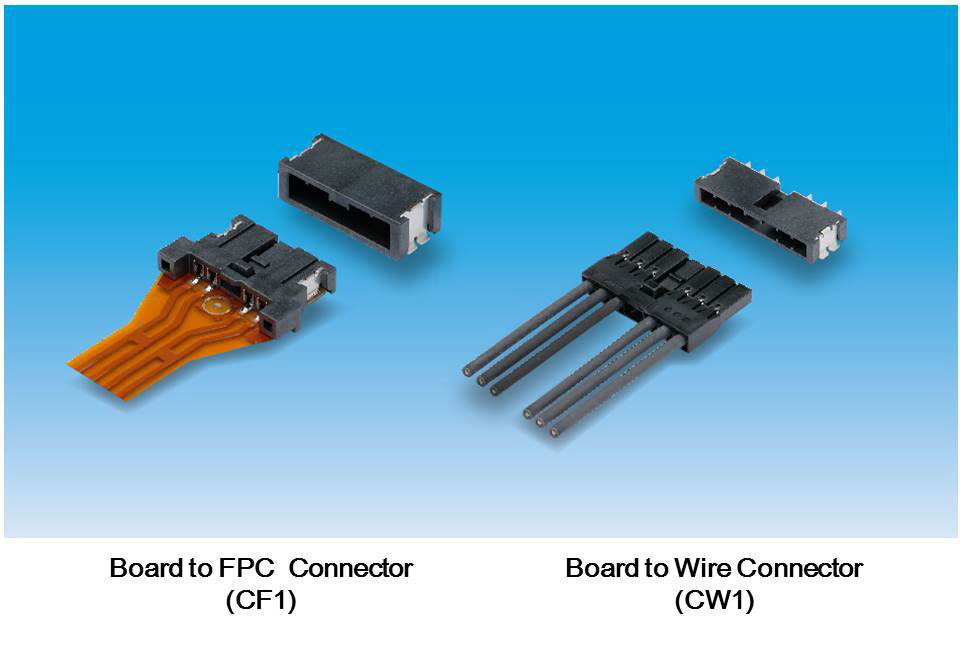

One of these is a "Board to FPC Connector", the first of its kind in the industry*1 that is suitable for cable connection to daytime running lights (DRLs), which are kept switched on during the daytime, and in rear lamps.

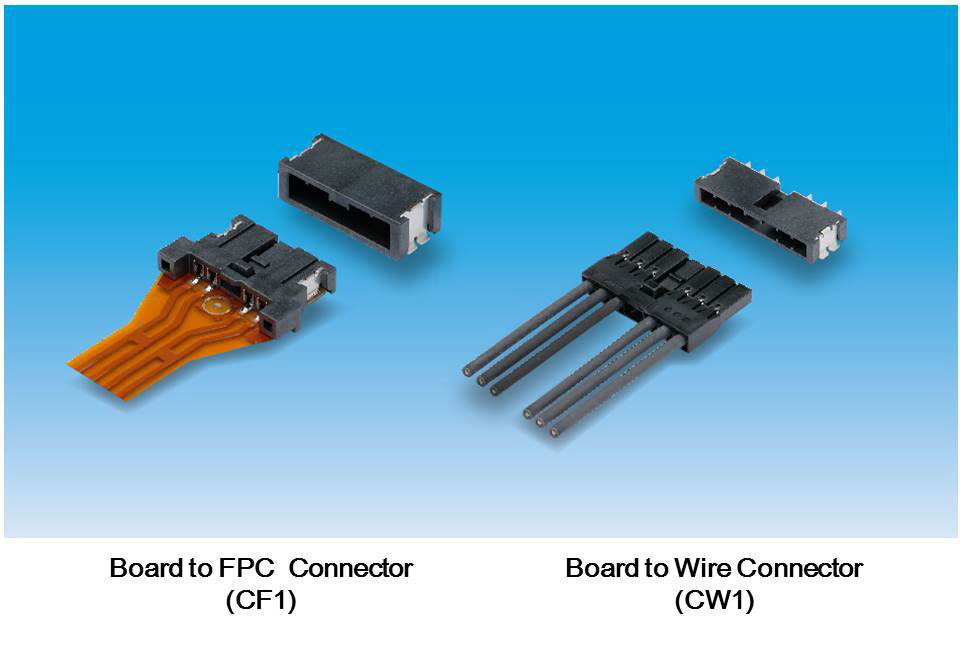

The other is a "Board to Wire Connector", the lowest-profile connector in the industry*2 that is suitable for LED headlamp modules.

These new products have the following features:

[Board to FPC Connector]

1. This connector has a metal terminal connection structure that eliminates the need for FPC contacts for the first time in the industry*1, realizing direct connection between the LED-chip-mounted FPC and the control power board. It requires no relay harness, allowing the use of fewer components and fewer man-hours.

2. The connector's double-clip structure ensures its resistance to vibration and temperatures up to 125 degrees Celsius, both extremely desirable properties for headlamps.

[Board to Wire Connector]

1. This connector has an in-house-developed terminal shape that gives the connector a height of only 3.4 mm, the lowest profile of any connector in the industry*2. This low profile connector exerts a minimal effect on the lighting angle of the LED, enabling smaller and low profile LED lamp modules to be easily manufactured.

2. The connector's unique LED headlamp terminal structure gives it vital vibration resistance as well as heat resistance up to 125 degrees Celsius.

*1: On June 8, 2016, it was developed as a two-piece type board to FPC connector (according to research by Panasonic).

*2: On June 8, 2016, it was developed as a connector for in-vehicle LED lamp modules (according to research by Panasonic).