Plummeting LED lighting prices and net profits in the LED industry, has allowed LED filaments to emerge as the black horse in the market, placing it under the market spotlight. LED filaments were formerly plagued with manufacturing technology and yield rate issues, and in the past few years Epistar’s patent suits has placed LED filaments under the lime light again, reported China's LED Patent Association (LPA).

Epistar announced recently it settled a lawsuit against Adamax over LED filament infringement in U.S. District Court for the Northern District of California for an undisclosed sum.

In the plaintiff submitted to the court on Aug. 30, 2016, the company filed patent infringement suits against Adamax (d/b/a Newhouse Lighting) because its 3.5W Vintage Edison Filament Bulbs infringed U.S. Patent Numbers 6,346,771, titled “High Power LED Lamp,” 7,489,068 titled “Light Emitting Device,” 7,560,738 titled “Light-Emitting Diode Array Having An Adhesive Layer,” 8,240,881 titled “Light-Emitting Device Package,” 8,791,467 titled “Light Emitting Diode And Method Of Making The Same,” and 9,065,022 titled “Light-Emitting Apparatus.”

What are LED filaments?

LED filaments are an innovative technology, where a normal 3.0 V LED chip is adhered inside a leadframe cup with epoxy, and dispensers are used in the packaging process to make PLCC packages. LED filaments basically comprise of many LED chips placed next to each other in a series connection onto a glass substrate, and then are compressed into LED packages. The LED luminaires possess low current and high voltage features, which effectively lowers LED thermal dissipation and driver costs, giving it a competitive edge.

These LED filaments are a new type of LED packaging, and one of the most popular on the market because it can be used to make LED bulbs similar to incandescent bulbs, which can easily achieve omnidirectional 360 degree lighting.

LED filaments usually are made with 28 pieces of 1016 LEDs that are 0.02W, these LED chips use series connection to be placed on sapphire substrates that are 38 mm long and 1.5 mm wide, before it is coated with phosphor. LED filaments tend to use 10 mA electric current to drive the devices, and use 84V and have a luminous efficiency of 0.84W and light output of 100 lm. The LEDs lumen efficiency can reach 120 lm/W, and combined with red LED chips the CRI can reach above 95, and possess excellent optoelectronic features.

By using LED filaments the companies can make small to mid-power LED bulbs or candle lights that usually comprise of four LED filaments. The filaments can be arranged in two series connections or two parallel connections to reach the power output of 3.6W LED bulb or candle light, or reach 400 lm luminous output that can be used to replace 40W incandescent bulbs.

Incandescent bulb manufacturers can use current technology and production lines to make LED filament bulbs, which use existing incandescent bulb glass leadframe designs to connect the LED filaments. By using special highly transmissivity incandescent bulb technology and automatic glass bulb blowing technology to make incandescent LED bulbs with high C/P ratio.

Epistar’s patent strategy deployment

Taiwan’s largest LED epiwafer and chip manufacturer Epistar deployed its patent strategies through three stages.

Epistar acquired some primary LED filament patents at a very early stage, then it formed a very large patent network by writing technology patents that featured a wide scope. The company also has been following market developments closely and deploying its patent strategies in the supply chain.

From Table 1 and Graph 2 it can be seen Epistar deployed comprehensive patent filament strategies that cover LED chips, sapphire substrate, transparent substrates, thermal dissipation substrates and wide angle LED bulbs. The company’s LED filament portfolio especially covers filament packaging, and the company is prioritizing LED filament patents in recent years because its core LED filament technology is adhering the LED onto a transparent substrate. Epistar acquired most of LED filaments core patents in 2004 in U.S., Europe, China, and Taiwan. Epistar has licensed its LED filament patents to Cosmoled, Leedarson, FSL, and other LED manufacturers. Its patent license agreements signed with Cosmoled and Leedarson had recently expired, an Epistar spokesperson told LEDinside. The company is also open to inviting new clients to sign patent agreements to expand its strategic partnerships, expand its market, and acquire competitive advantages.

Table 1. Epistar's LED filament patents for making lamps

|

Patent No. |

Application date |

Patent description |

Image |

Notes |

|

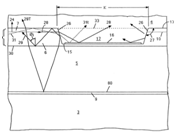

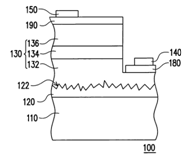

US6346771

High power LED lamp

|

1998-11-19

|

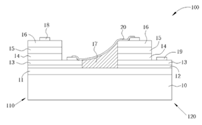

An LED lamp for generating incoherent visible light, comprising: a non-semiconductor member; a semiconductor structure formed over said non-semiconductor member and comprising lower and upper inorganic semiconductor layers of opposite conductivities and an active region generating LED light, said semiconductor structure having bottom and top faces and outer side faces; a patterned sapphire substrate (PSS) LED chip.

|

|

The patent originally owned by Unisplay was transferred to Epistar on Dec. 2, 2011.

|

|

US7489068

Light emitting device

|

2006-01-06

|

The patent is written to effectively to broaden its scope to incorporate transparent sapphire substrate and touches upon LED filament packages transparent substrate features.

|

|

Epistar was granted an invention patent on Feb. 10, 2009.

|

|

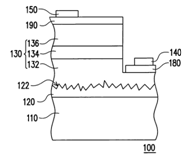

US7560738

LED array having an adhesive layer

|

2005-03-11 |

Many LED chips electrically connected with metallic wire bonding onto a transparent substrate. The patent directly addresses connecting multiple LED chips in LED filaments.

|

|

Epistar received an invention patent on July 14, 2009. |

|

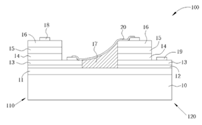

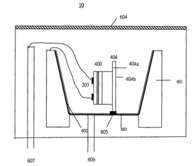

US8240881

LED Package

|

2008-11-13 |

The LED chip is attached to a first surface of a transparent substrate, which addresses LED filaments transparent substrate feature. The patent’s original solution was to package the chip onto a transparent substrate before placing it into a package leadframe. It has been proven overtime this solution does nto have any immediate application fields, but the LED chip packaged onto a transparent substrate touches upon LED filament package. |

|

Epistar was granted an invention patent by USTPO on Aug. 14, 2012. |

|

US8791467

LED and method of making the same |

2011-05-11 |

LED chip adhered to a substrate with high thermal dissipation. |

|

Epistar receives invention patent on July 29, 2014. |

|

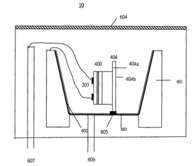

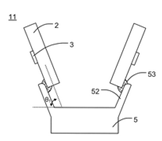

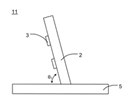

US9065022

Light emitting apparatus

|

2013-03-18 |

A LED filament bulb with wide beam angle. |

|

Epistar is granted an invention patent on June 23, 2016. |

|

US9065022

Light emitting apparatus

|

|

|

|

|

The types of patent strategies include blocking, shotgun approach, carpet bombing, destroyer strategy, surrounding strategy, scarecrow strategy, market segmentation, “freedom to design”, diversion tactics and others. Japanese companies tend to use a fencing strategy where they apply for many patent applications to use it to surround its competitors, and where most of these patents are basic or core patents. The companies use these strategies to block competitors commercialization process, and force rivals R&D, plus manufacturing process into a dead end. These also push companies into cross-patent licensing, and these strategies can only be implemented by larger companies because of the large number of patent applications required which can be a costly process. Each manufacturer will adjust its strategies to meet different development situations, and use different patent portfolios to protect company interests.