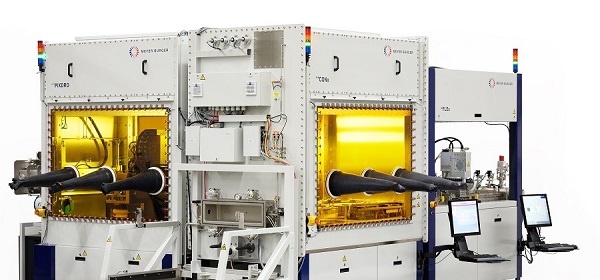

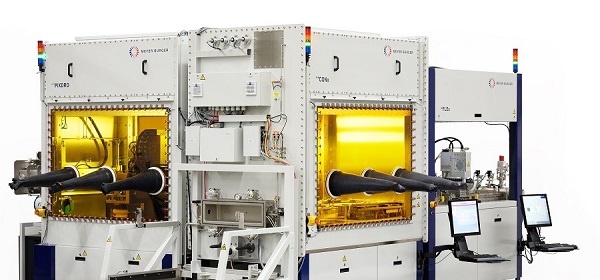

Meyer Burger has shipped a CONx TFE thin film encapsulation system consisting of an inkjet printer and PECVD system to an Asian customer for encapsulation of OLEDs and other flexible electronics applications. This latest order confirms the market’s recognition of Meyer Burger’s integral and fully automated thin film encapsulation system.

Meyer Burger (Netherlands) has delivered an industrialized CONx TFE cluster system for the thin film encapsulation of OLED devices and other flexible electronics applications to a customer in Asia.

|

|

Meyer Berger shipped an automated CON x TFE system for OLED encapsulation to an Asian client. (Meyer Berger/LEDinside) |

The new integral and fully automated CONx TFE system comprises Meyer Burger’s proprietary remote plasma PECVD for inorganic coating and its PiXDRO inkjet printing technology for the deposition of accurately positioned and homogeneous organic layers which enables Meyer Burger’s customers to move to thinner and more flexible devices. The system also provides excellent water and oxygen barrier properties without compromising the optical transparency of the encapsulation layer. In order to avoid particle contamination which is an important concern in barrier fabrication, Meyer Burger developed a process flow without shadow masks while engineering a clean and inert environment and particle free handling of the substrates.

Key system attributes such as low temperature processing and low ion bombardment, excellent layer homogeneity and conformity combined the high output of thousands of OLED devices per hour as well as the possibility for seamless integration in overall OLED production flows are all the reasons why customers are choosing Meyer Burger’s CONx TFE cluster system.

Meyer Burger has received orders for a number of R&D thin film encapsulation systems. The current order for the industry-proven CONx TFE thin film encapsulation equipment proves that the growing OLED market is scaling up its production capacity and that the customers trust in Meyer Burger’s long-standing experience as a provider of inkjet printers and thin film coating tools.