Key Takeaways:

I. A new trend found at GILE 2017 is that LED makers are now working on high CRI LED packages projecting lights close to sunlights (natural lights) as they possibly can.

II. Zhongke Xinyuan showcased unprecedented K-CoB packages with patented glass-ceramic phosphors.

III. HC SemiTek has started the development of Micro LED.

It is inevitable to find some exhibitors keep harping on the same old products at a tremendous lighting exposition as GILE 2017 (of course it is for they were there to trade), but it is also fairly reasonable to spot something new, let alone when walking around in the hall of LED chips and packages (of which the market is now a deep red ocean in China).

In recent years, after the global economic slowdown in 2014, China’s LED chip and package industry recuperated and its market has now grown to an astronomical scale in light of the inpouring of international capacity and the emergence of new markets such as automotive lighting, horticultural lighting, UV LED, and fine-pitch display that created new demands. In order to survive in this massive red ocean with fierce competitions, Chinese manufacturers have gone to great lengths to advance their production by upgrading their manufacturing technologies, which, interestingly, slowly transitioned them away from the stereotype that ‘Made in China’ is a synonym for low quality.

Here LEDinside picked a few major Chinese LED packagers whose innovations displayed at GILE 2017 represented the breakthrough in China’s LED industry.

Shenzhen Refond Optoelectronics

At GILE 2017, the majority of Chinese upstream companies showcased their comprehensive portfolios of LED packages and modules, and Refond Opto. was one of them. Covering applications from general lighting and LED filaments to UV LED and display technology, Refond’s LED packages shown included UV 3535, UV 3838, full spectrum series 2835 and 3528 for decorative lighting, and small scale SMD LED for out-door displays. This year, the company also disclosed its killer solution- IPSL, which underpinned the quality of its LED packages and kept them from sulfur corrosion and high luminous decay.

|

|

Refond showcased its UV LEDs used in horticultural lighting. (LEDinside) |

|

|

A closed-up of Refond's 38mm filaments (LEDinside) |

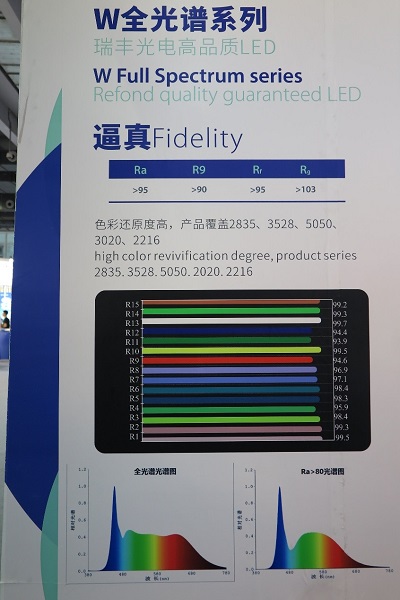

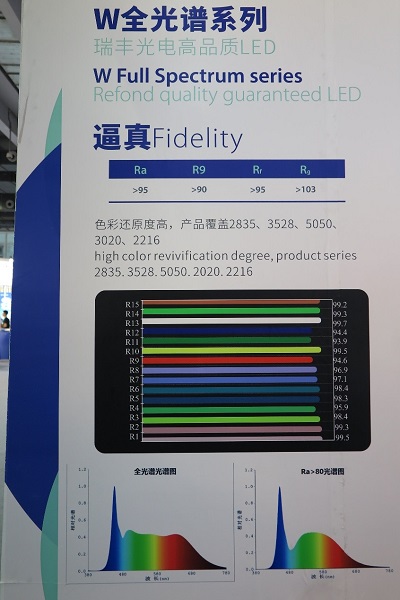

In terms of the quality of light, both international and Chinese LED packagers, are now endeavouring to develop packages emitting lights as close to sun lights as possible to rectify the problem of glare and to create a visual world with high color fidelity. In accordance with this, Refond launched the W Full Spectrum series, coming in specifications of 2835, 3528, 5050, 2020, and 2216, which are RoHS compliant, have high reliability and cover a full CCT range.

|

|

The W Full Spectrum series were said to emit light rays simulating sunlight. (LEDinside) |

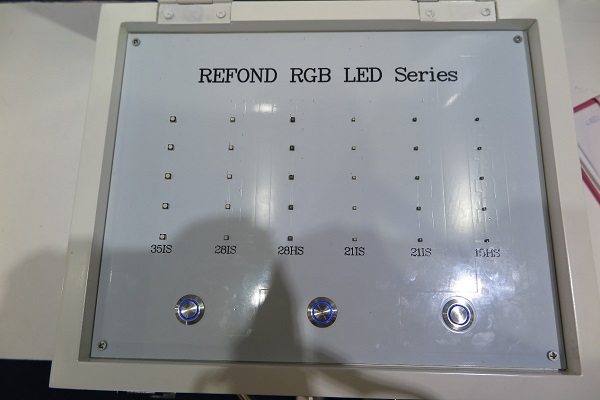

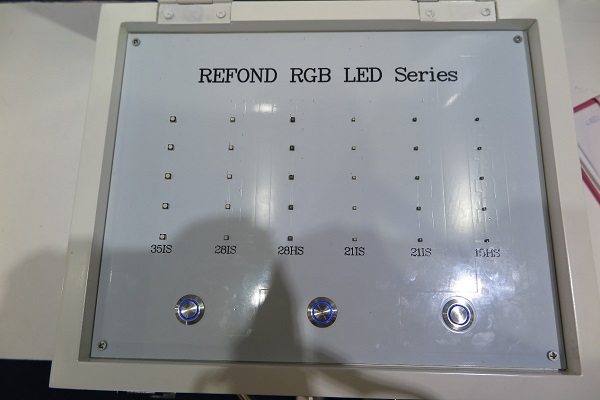

For outdoor display producers, Refond offered, as the company’s representative Mr. Dong Zhong claimed, the smallest SMD LED, sized in 1.6*1.7*1.6 mm, compared with its equivalents in China. With an atomizing finish and mounted in black lead-frames, these LEDs were already used to construct a 730-square-meter outdoor display outside a department store in Beijing.

|

|

Refond's small scale RGB LED series for outdoor HD displays (LEDinside) |

A major achievement Refond Optoelectronics has attained to advance the stability of its LED packages was the ultimate solution-IPSL, a significant know-how Refond Opto. developed to outperform its rivals by adding a thin layer of IPSL to cover the surface of the silver plate to prevent the formation of sulfur dioxide and stabilize the luminous flux of the package (A side view of an EMC 3030 package structure with IPSL is shown in the image below).

|

|

Refond Opto. stated its ultimate solution IPSL was the linchpin differentiating the company's products from their equivalents. (LEDinside) |

Zhongke Xiyuan Technology

|

|

A brief history of Zhongke Xiyuan Technology Co.,Ltd. (LEDinside) |

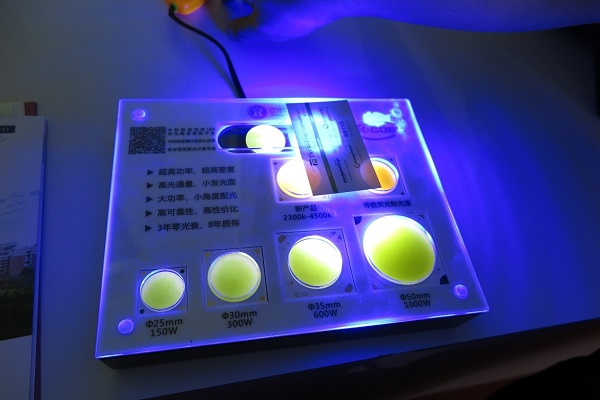

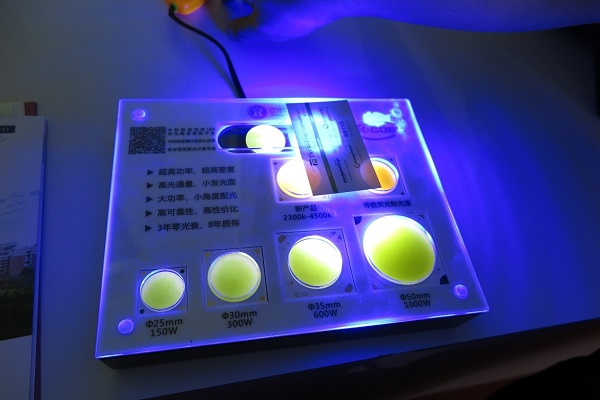

While other LED packagers were still using conventional phosphor powders to produce white LEDs, Zhongke Xiyuan, a JV established in 2013 in Fujian, began its research and development of glass ceramic phosphor and successfully gained the patent CN105428498B after a year of attempt. This core material and the intellectual property not only supported Zhongke Xiyuan to stay independent away from Nichia’s dominant white LED manufacturing technique but raised the willingness of overseas clients to place orders for the company’s high power K-CoB series innovated with ceramic phosphors and launched in mid-2016. The ceramic phosphor holds an edge over the traditional powder phosphor in regards to thermal conductivity, most notably at temperatures over 200°C.

The K-CoB series feature ultra-high power ranging from 150W to 1000W and emit when powered highly concentrated light beams able to reach 40 meters at most. The packages have been used on locations such as airports, train stations, and playfields.

|

|

A demonstration of using a piece of ceramic phosphor to create a white LED [before placing the ceramic phosphor over the CoB package] (LEDinside) |

|

|

A demonstration of using a piece of ceramic phosphor to create a white LED [after the ceramic phosphor overlaps the CoB package] (LEDinside) |

HC SemiTek

|

|

A glimpse of HC SemiTek's booth (LEDinside) |

In retrospect, the joint momentum from markets of fine-pitch display and high efficient lighting boosted the demand for small-scale chips, leading the supply in the market to become tightened and prices of certain chips rose. HC SemiTek ramped up its production capacity in response, causing the concentration ratio and profitability of the company continue to increase. At the fair, HC SemiTek showcased a myriad of chip series- the High-voltage ‘Bright’ series, the Filament ‘Glorious’ series, the Flip ‘Shining’ series and the chip series for IR LEDs, LED backlights and displays, each of which featured properties specifically for a certain application.

|

|

HC SemiTek's high efficiency LED chip won the Alighting Award 2017. (LEDinside) |

|

|

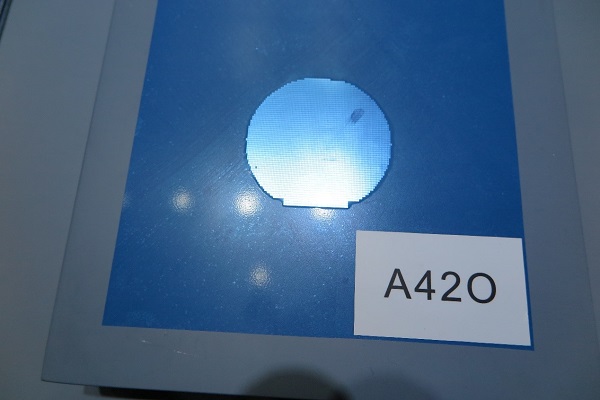

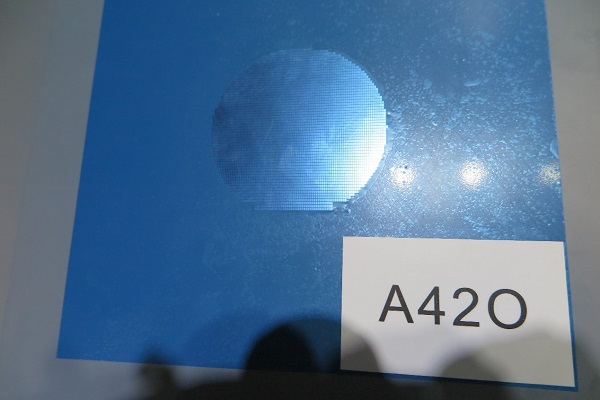

|

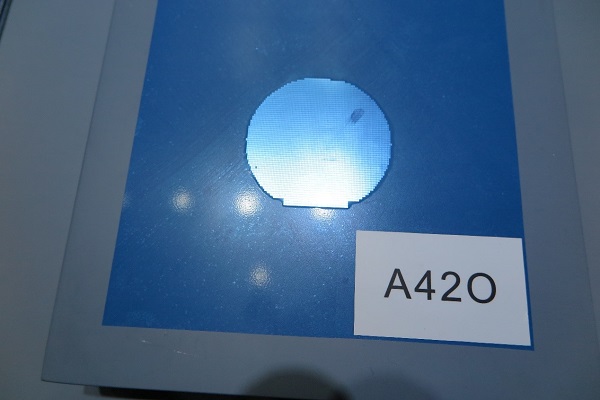

The wafer samples of HC SemiTek's high efficiency LED chip (LEDinside) |

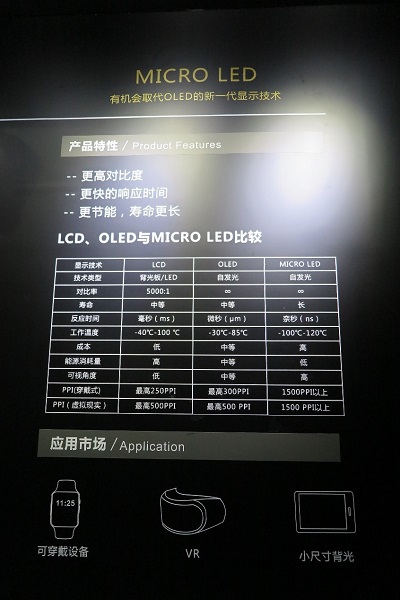

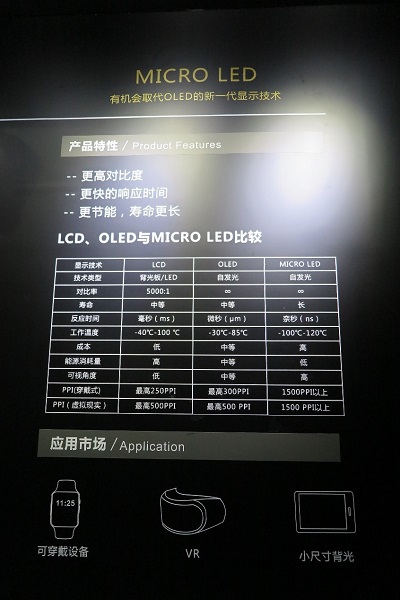

In particular, LEDinside found HC SemiTek showed, without demonstrated samples though, a briefing of Micro LED. According to one of HC SemiTek’s staff, the company has currently got it under development. He also stated two major challenges HC SemiTek as well as other chip makers who also started the R&D of Micro LED have been struggling to overcome and, predictably, they lay in the maintenance of epi uniformity and the inspection of chips. However, whether HC SemiTek encountered any other difficulties or how far its development has gone remained unknown as no more detail was given.

|

|

A briefing of Micro LED at HC SemiTek's booth (LEDinside) |

Coming up next in Part II are the other three companies: Honglitronic, Smalite, and LatticePower.