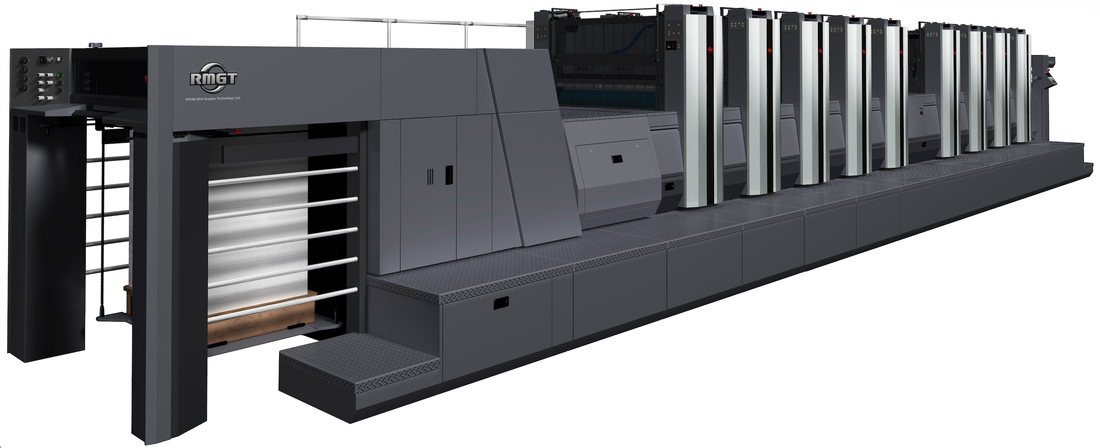

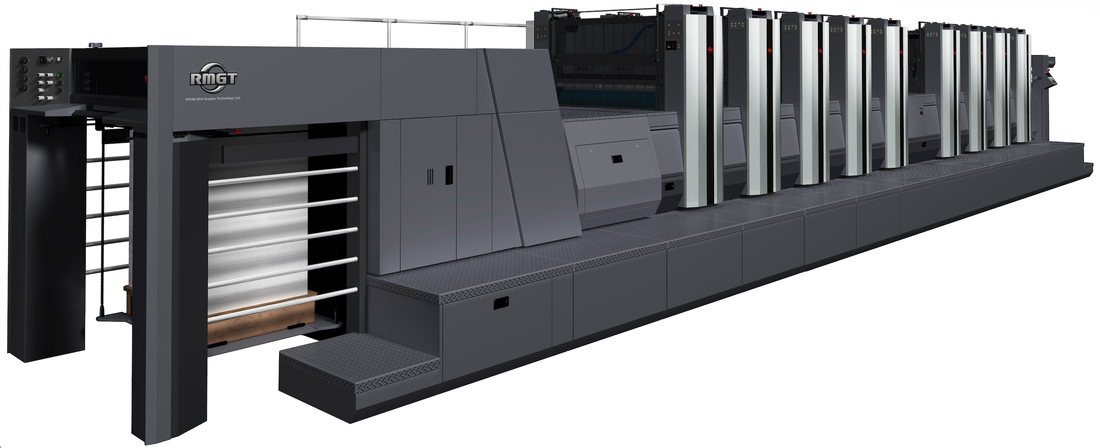

Azar Printing purchased the 47th RMGT 9 Series press in the North America, and will be taking delivery of the unit in September immediately after the PRINT 17 trade show. The new RMGT 920PF-8+CC will replace two 4-Up presses — an older 8-color press, as well as a 6-color with coater press. The new press equipped with RMGT’s fully automatic plate changing, SMART Insta.Color make-ready technology and LED UV Curing for both 4/4 perfecting and LED-UV curable coatings will all represent firsts in the St. Louis marketplace.

|

|

The RMGT 920PF-8+CC+LED-UV press. (Image: RYOBI MHI Graphic Technology) |

“They’ve been great presses, but one is getting to be 20 years old and they needed to be replaced,” said Mark Azar, owner of the company. “I’ve been looking for a while now, and I considered a 40-inch press, but I don’t have the power, and I don’t have the pad — I just don’t have room for a 40-inch. This 8-up press fits on the same pad as our older 4-up press, and uses less electricity. Also, I can get a 16-page signature, so this press doubles capacity. This is a big deal for us.”

Azar Printing’s primary market segment will continue to be the production of short to medium run booklets used in both B2B and Direct Mail Marketing. However, the addition of LED-UV curing of both sides of the sheet, coupled with special effects coatings and straight 8-color print production will provide plenty of upside growth for this incredibly efficient and well managed organization. “We will continue to be a reliable print producer in our well-developed market space, but having the added capabilities of this state-of-the-art RMGT 9 Series will let us evolve into new markets.” states Mark Azar. “We are excited to see the impact this new technology will make on our company and most importantly our customers projects.”

In addition to doubling the sheet-size being produced the new RMGT 9 Series press will tremendously improve turnaround time and print quality for Azar Printing’s demanding customers that come from a wide range of industries, including automotive and furniture businesses in the greater St. Louis area. Mark Azar chose to add the LED UV because he runs a clean shop, and the lack of powder in the RMGT 9 Series press will allow them to more easily move jobs directly into their post-press and mailing equipment without marking or jamming.

The new RMGT also boasts impressive environmental credentials. The unique LED-UV curing technology uses 80% less energy than traditional UV curing technology, which will help Azar Printing reduce their electrical consumption by 60% overall. Additionally, the LED-UV inks don’t emit volatile organic compounds (VOCs), which will provide a cleaner and safer workplace for Mark’s very talented staff.

But perhaps the strongest advantage the new press will bring is the speed to market that combining single-pass printing and LED-UV instant curing provides. In today’s fast-paced business climate the RMGT 9 Series truly provides an offset print quality alternative to digital turnaround times at a much lower cost than toner or ink jet. Azar Printing is pleased to bring this capability to the St. Louis area.

“Having worked with Mark for over a decade we are excited about the Azar Printing installation,” says Chris Manley, President of Graphco. “This marks 47 installations in North America of the 9 Series press, and we are only now picking up speed. As more printers realize the incredible benefits of this press — a 16-page signature in the smallest footprint on the market, UV LED curing, and RMGT’s well known automation the 9 Series brings profitability at much shorter run lengths than other offset presses. Azar Printing joins an elite group of shops who have already discovered the difference this press can make, and we are looking forward to continuing to help Mark and the rest of his team as they take their business to the next level.”