Through a European project, VTT Technical Research Centre of Finland and Neonelektro have developed new types of LED displays that combine the flexibility, low cost and high technical performance enabled by roll-to-roll mass manufacturing technology.

|

|

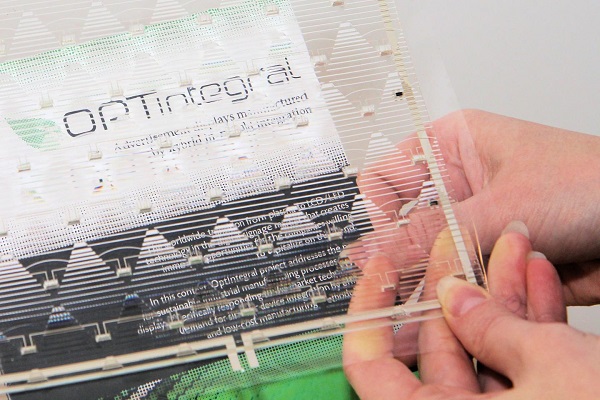

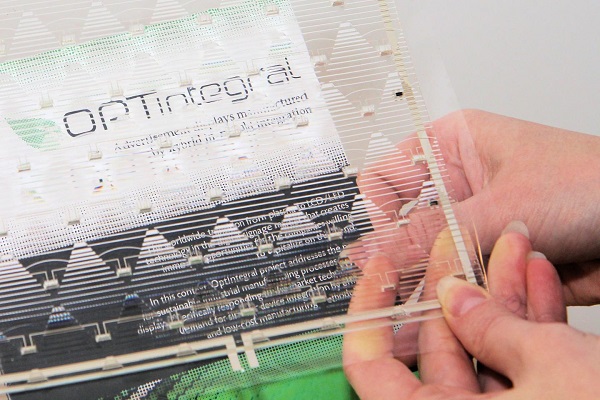

In the Optintegral project, a flexible, thin and transparent light panel was developed by integrating a flexible LED foil with a plastic, overmoulded structure. Optical features were added to the panel surface during the overmoulding, which focused light from the LEDs in the desired direction. (Image: VTT) |

"Flexible, light weight, and of an easily customisable size, the LED advertising panel enables the creation of a dynamic look for a large area applications, or those that require a 3D shape, such as vehicles," says Project Manager Eveliina Juntunen of VTT.

The OptIntegral project, which was completed at the end of January, used a hybrid integration manufacturing process (combining injection moulding and printed electronics), in which the flexible electronics substrate was immersed in an overmoulded polymer. Overmoulding protects the components and enables additional features, such as optical and mechanical structures to be integrated during a single processing step.

This technology was applied to the production of large area LED displays during the project. Overmoulding was used to add optical structures to the display elements, improving the visual appearance of the product. In addition, VTT's measurements indicate that overmoulding lowers the temperature of the LEDs by around 20%, which is significant in terms of the reliability and efficiency of LEDs. This makes the displays energy-efficient, lightweight, flexible and even three-dimensional.

VTT Technical Research Centre of Finland (VTT) used a roll-to-roll process to make flexible LED substrates for the displays, refining the process to make it more productive. Neonelektro Oy developed an overmoulded RGB display element manufactured using the roll-to-roll technique.

"Interest in dynamic backlighting has grown dramatically during the project, and we have developed a new product family based on it. Developing a technology to meet such demand has opened up new markets for us," says Matti Koponen, who is in charge of product development at Neonelektro.