Building upon the progress made during a recent workshop, the Lighting Research Center (LRC) at Rensselaer Polytechnic Institute has formally established the Additive Manufacturing for Lighting Consortium. The consortium will help bridge the knowledge gap between the lighting and 3D printing industries and build a collaboration for successful adoption of additive manufacturing for high-quality, value-added lighting.

The consortium, composed of lighting and 3D printer and material manufacturers, convened its first meeting on April 2 and is now setting a course to understanding and assimilating additive manufacturing as a viable option for the lighting, building, construction, and allied lighting industries. The objectives for the consortium’s first year include market assessment, education, and collaboration on pilot research projects. These activities will help the group to better understand the needs of the two industries, the possibilities, and the present status of the additive manufacturing industry’s capabilities relevant to lighting.

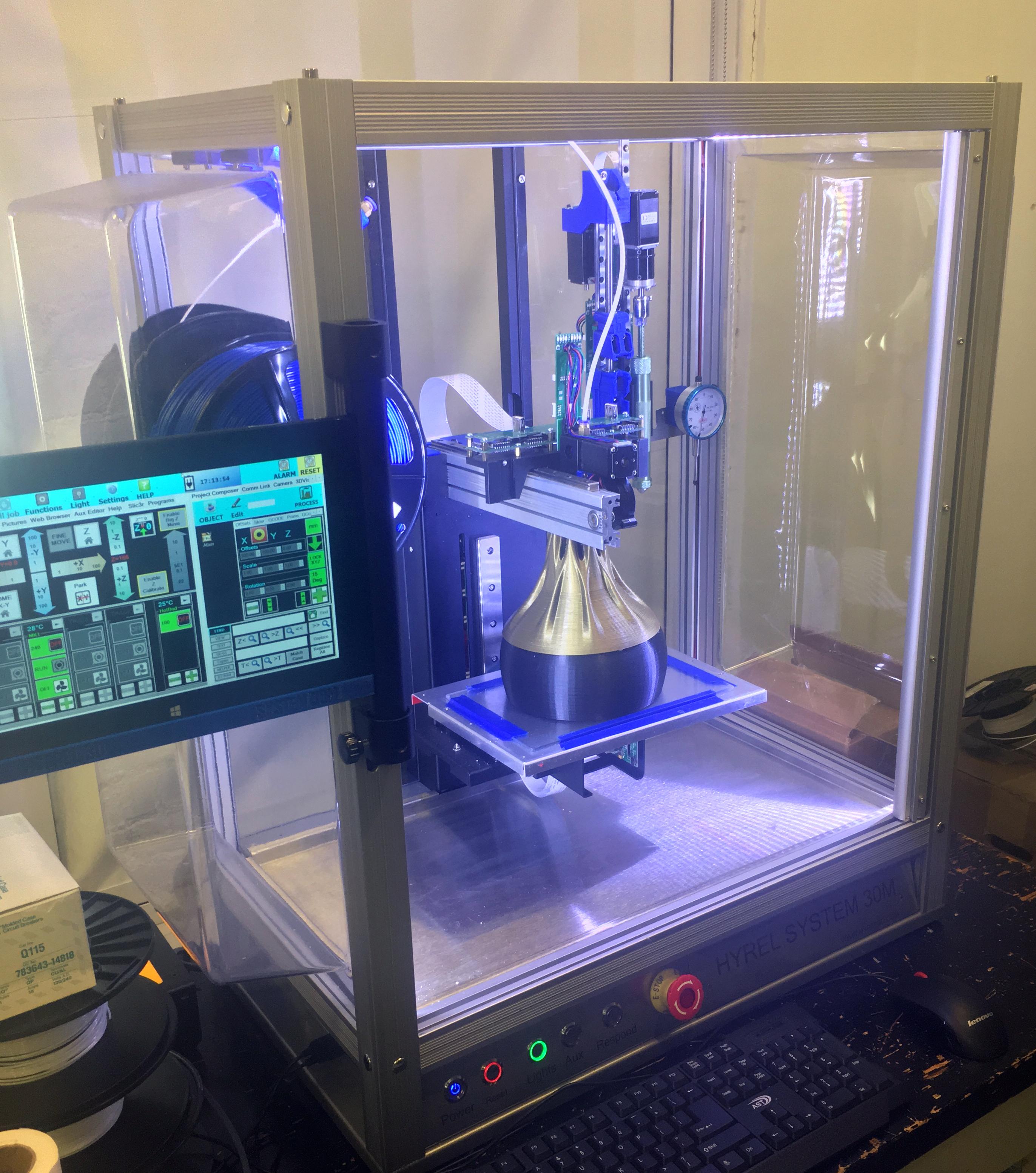

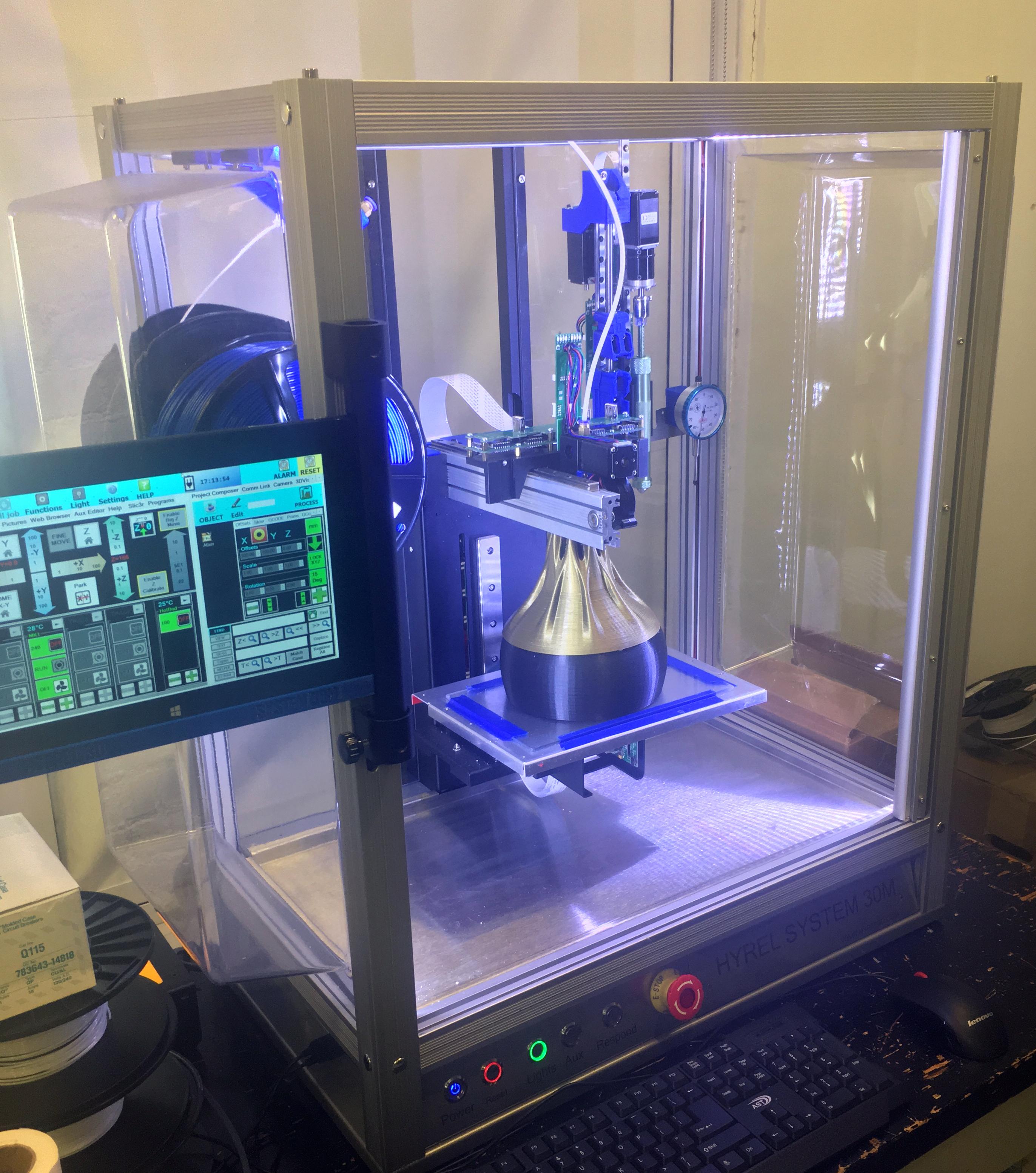

(Image: LRC)

Nadarajah Narendran, Ph.D., the LRC’s Director of Research, said the group’s long-term goal is to build a center of excellence that will offer best practices and solutions for additive manufacturing of lighting systems. “In the future, we hope that the consortium will provide market intelligence, technology guidance, and standards representation, among other competency-building activities, which will enable companies to address this transformation proactively,” he said.

The potential benefits of 3D printing for lighting include the ability for manufacturers to create and rapidly print custom products on demand that are uniquely designed for the spaces to be illuminated, improving aesthetics, functionality, and manufacturing costs. Research is still needed to advance the integration of 3D printing into the lighting industry, and the Lighting Research Center has conducted initial investigations into the potential for printing different types of lighting components.