As LCD technologies advance, you may often hear about words like LCD,

LED, OLED, as well as popular display techniques using Micro LEDs, Mini LEDs, and Micro OLEDs. Have you ever tried to figure out these confusing terms but still don’t have any clue about them? Here

’, we’ll explain the said trendy technologies—in simple words—and compare them to older technologies, so that you can quickly grasp their main ideas.

What’s the Difference between LCD, LED, and OLED?

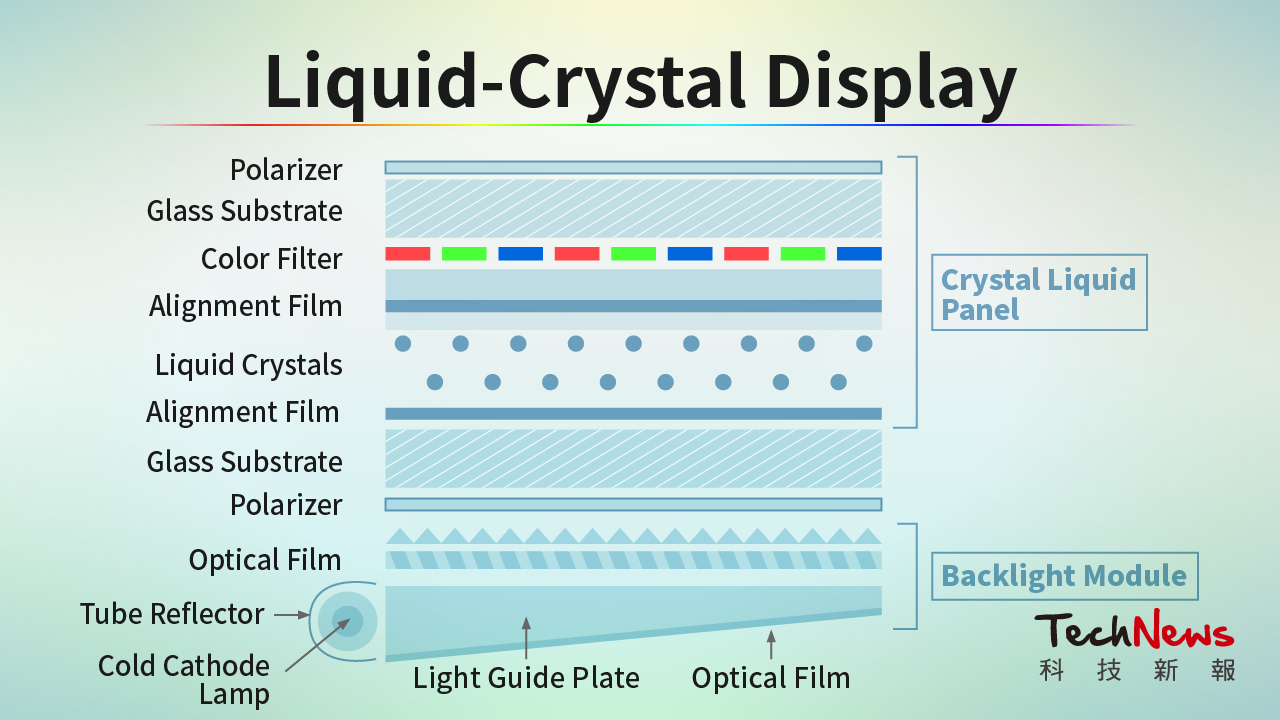

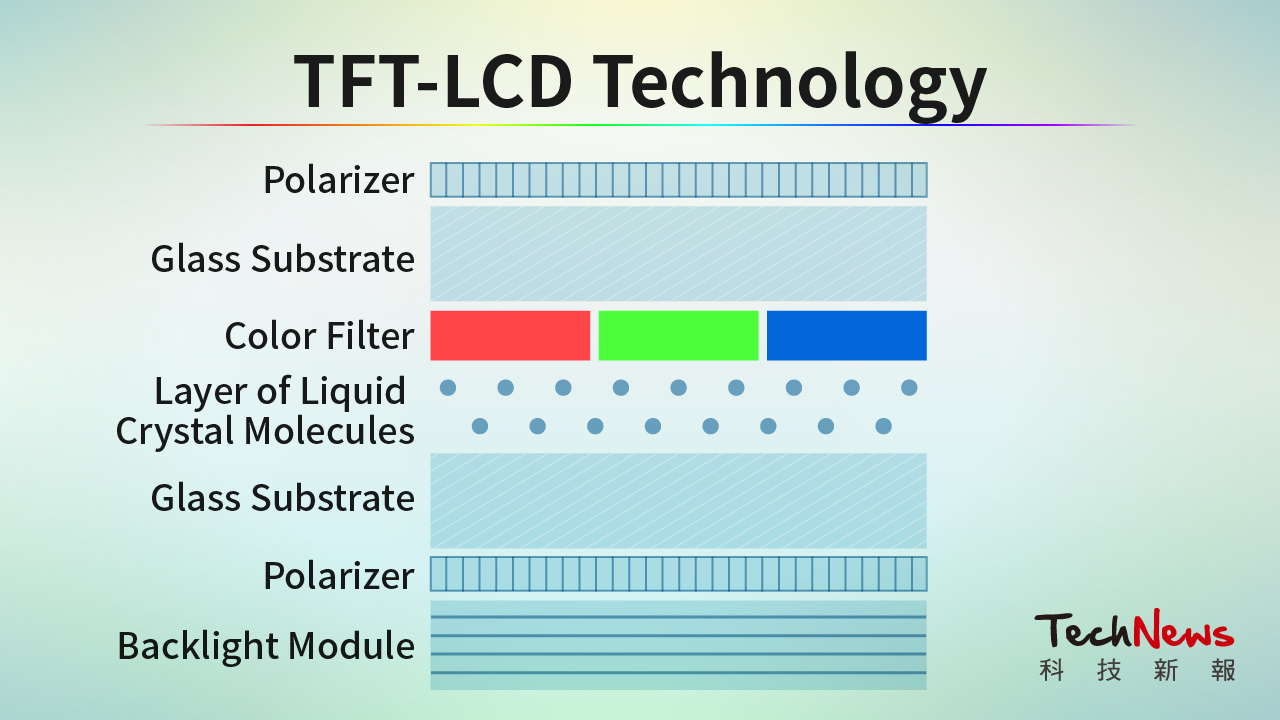

LCD stands for a “liquid crystal display”. Most LCDs now are produced using thin-film transistor technology (TFT LCDs), whereby a liquid crystal layer is sandwiched between two glass substrates, with the upper substrate being a color filter and the bottom one embedded with a transistor. When current flows through the transistor and causes electric field changes, the rotation structure of liquid crystal molecules are twisted, which then alters the rotational degree of light passing from it. The light thus illuminates the color filter in different proportions, enabling the LCD to generate different colors.

▲ TFT-LCD technology is most commonly used for LCD panels (Source: TechNews)

To date, LCD technology is considerably mature, allowing the production of general computer and TV screens at low cost, which makes it a fundamental technology of consumer products.

▲ The principle of how an average LCD produces images (Source: TechNews)

That’s the basics of LCDs. Now let’s move on to LEDs and OLEDs.

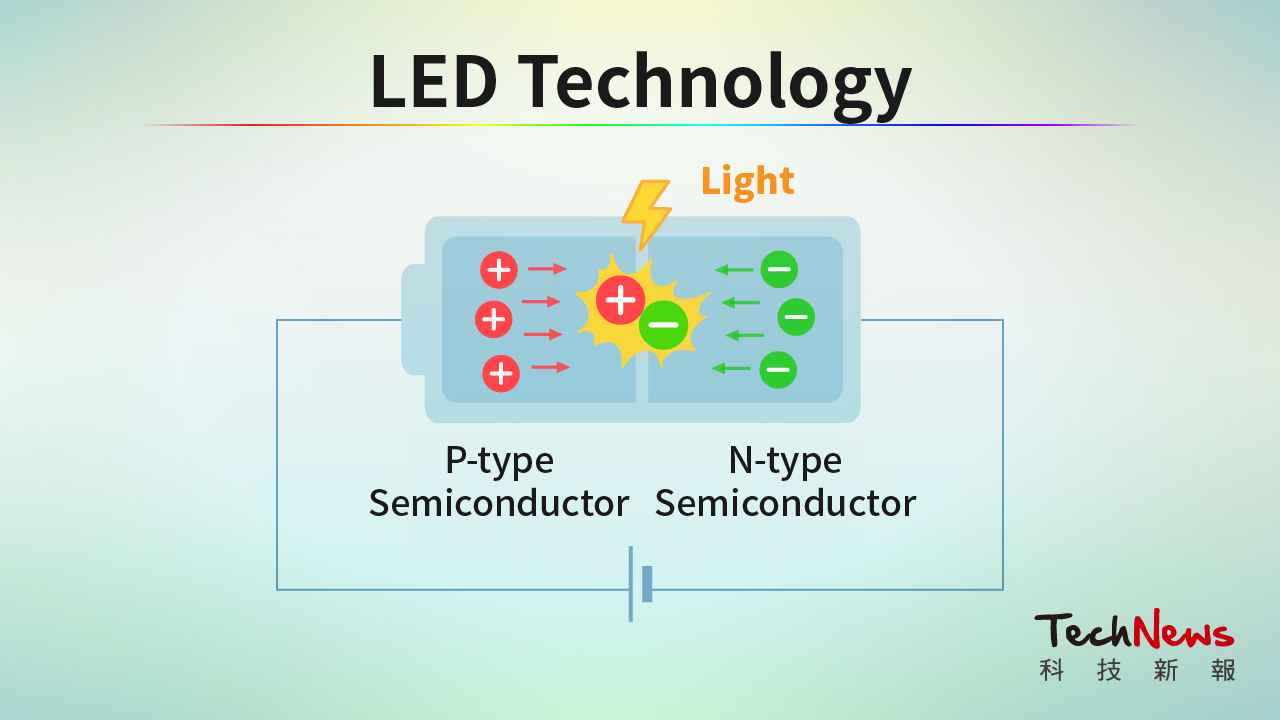

LED is short for a “light-emitting diode”, a semiconductor light source that transforms electrical energy into light energy, in which voltage is applied through the anode and cathode terminals. When current flows, electrons are combined with holes, prompting the remaining energy to be released through visible light. Depending on the material used, photon energy creates light with different wavelengths. Direct-lit LEDs are often applied to outdoor video walls and traffic lights, while LED chips are the mainstream component of TVs, monitor backlight sources, and illumination products.

▲ LED technology works by transforming electrical energy into light energy (Source: TechNews)

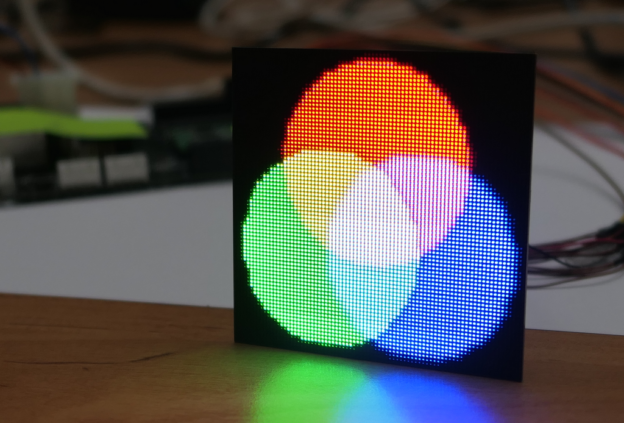

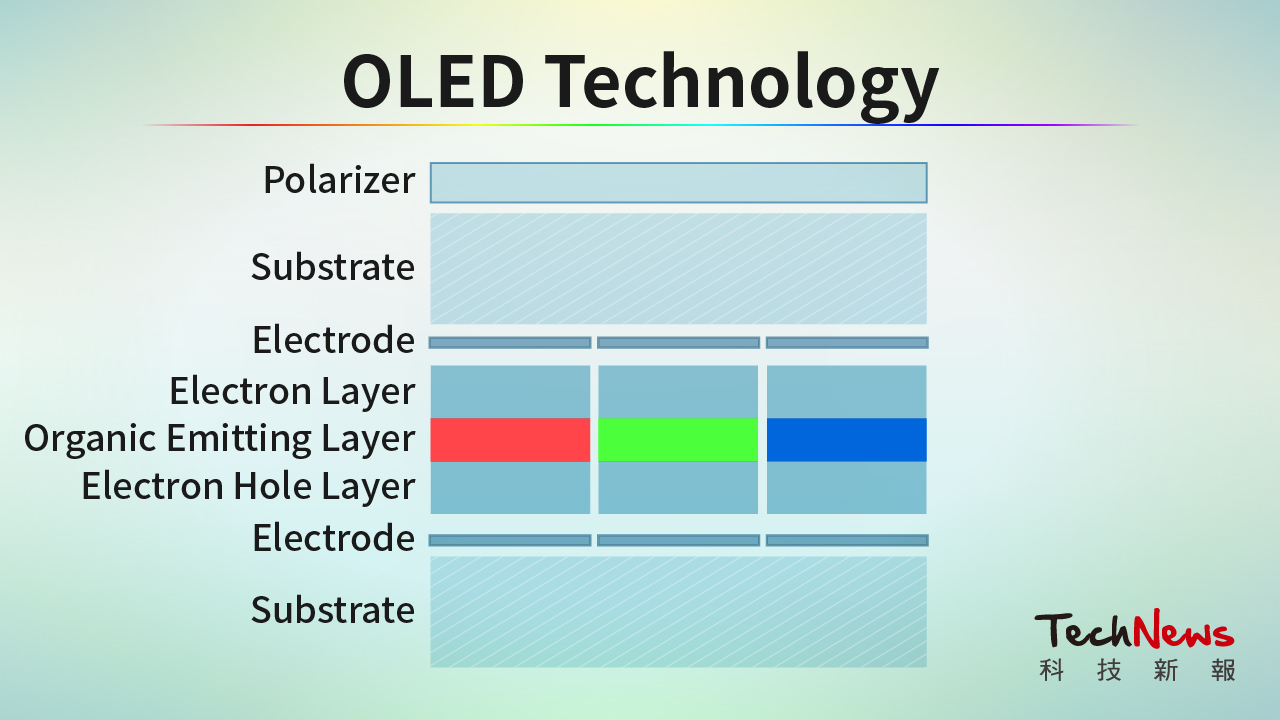

Despite a similar driving concept with LEDs, OLEDs adopt completely different materials. OLED is short for an “organic light-emitting diode”, of which the basic structure comprises an organic-material-based light-emitting layer fabricated on ITO glass. The light-emitting layer is covered with a low work-function metal electrode. Driven by external voltage, anode holes and cathode electrons are combined at the light-emitting layer, generating energy and making the diode glow. The component produces three primary colors (namely red, green, and blue light) using different material properties to create basic colors.

▲ The OLED technology (Source: TechNews)

The biggest difference between an OLED and LCD is their light-emitting methods. While an LED backplane and color filter is required for LCDs to product light, OLEDs are self-illuminating.

OLEDs can present vivid colors, have low power consumption, and are

rollable . However, their organic material will oxidize, which gives them a shorter lifespan. Moreover, OLEDs are prone to burn-in, are costly, and require the use of advanced techniques. Consequently, the light source is often used for small-screen products such as smartphones.

Mini LED vs. Micro LED: What’s the Difference?

Now we know the basic differences between LCDs, LEDs, and OLEDs. Let’s look at advanced display technologies like Mini LED, Micro LED, and Micro OLED.

The most obvious difference between Mini and Micro LEDs is their LED chip size, yet there is another distinction from the conceptual perspective. Mini LED refers to a “sub-millimeter light-emitting diode”, whereas Micro LED is short for a “micro light-emitting diode”.

The boundary between their chip size is 100 μm (i.e., 0.1 mm).

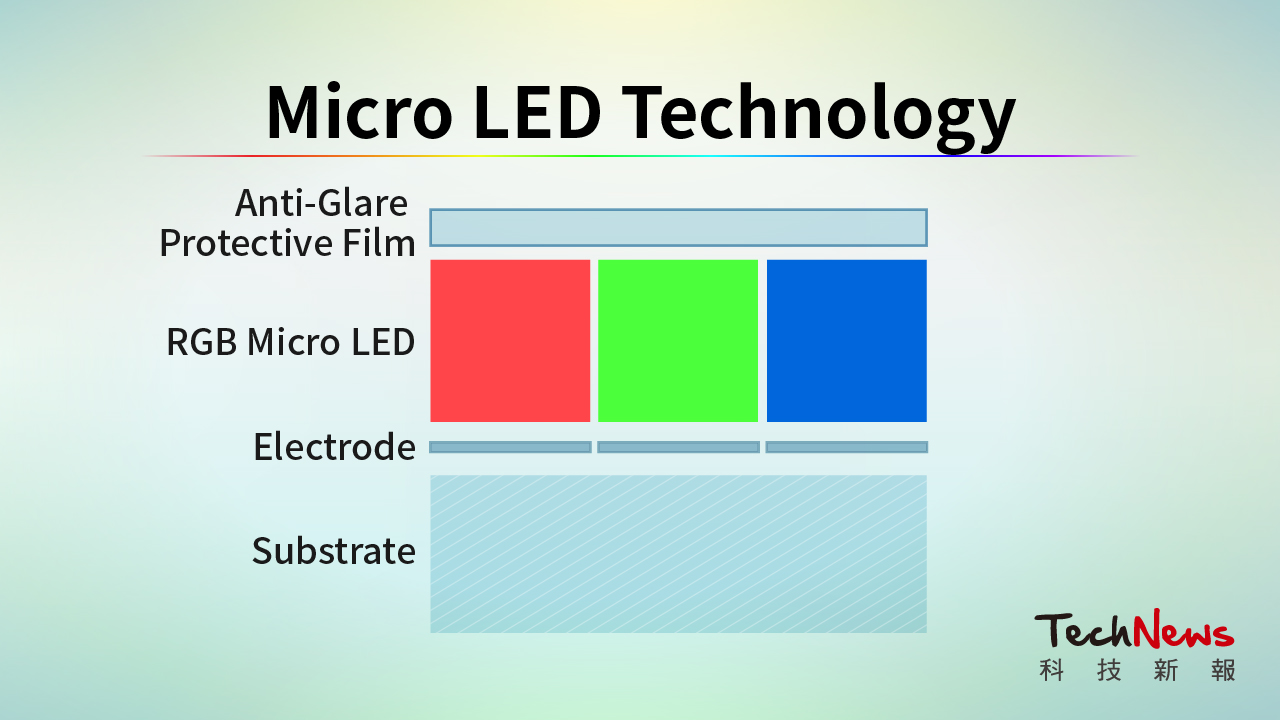

▲ Micro LED technology no longer requires color filters and crystal liquid layers (Source: TechNews)

Mini LEDs are regarded as a transition to Micro LEDs with better functions than conventional LED backlights, serving as light sources for LCD panels. Micro LEDs represent a cutting-edge display technology, whereby LED backlight sources are miniaturized and “metricized”. Being dedicated to individually driving inorganic self-illumination, Micro LED enables a longer product lifespan and boasts even better functions than OLED. Hence, it is a promising display technology in the next generation.

Mini LED technology is mainly applied to local dimming displays and large-size RGB fine-pitch displays. Local dimming allows the monitor to dim parts of the screen while keeping the other areas bright, achieving high contrast, high resolution, and high dynamic range imaging (HDR), of which the outcome is close to that of OLED. Further, Mini LED dies are used to produce large-size monitors with a pixel pitch of ≤1.0 mm; such technique not only enhances resolution but helps create new mainstream specs for displays.

Micro LED technology is expected to bring technical breakthroughs and its use is not limited to backlight sources. Because a Micro LED is hardly visible to naked eyes, LED dies emitting red, green, and blue light can be put together as one pixel point, realizing the “one pixel concept”. Therefore, a Micro LED product does not need any color filters and liquid crystal layers. The light-emitting structure of Micro LEDs is largely distinct from that of previous LCDs; thus, Micro LED is likely to be a game changer in the LCD industry.

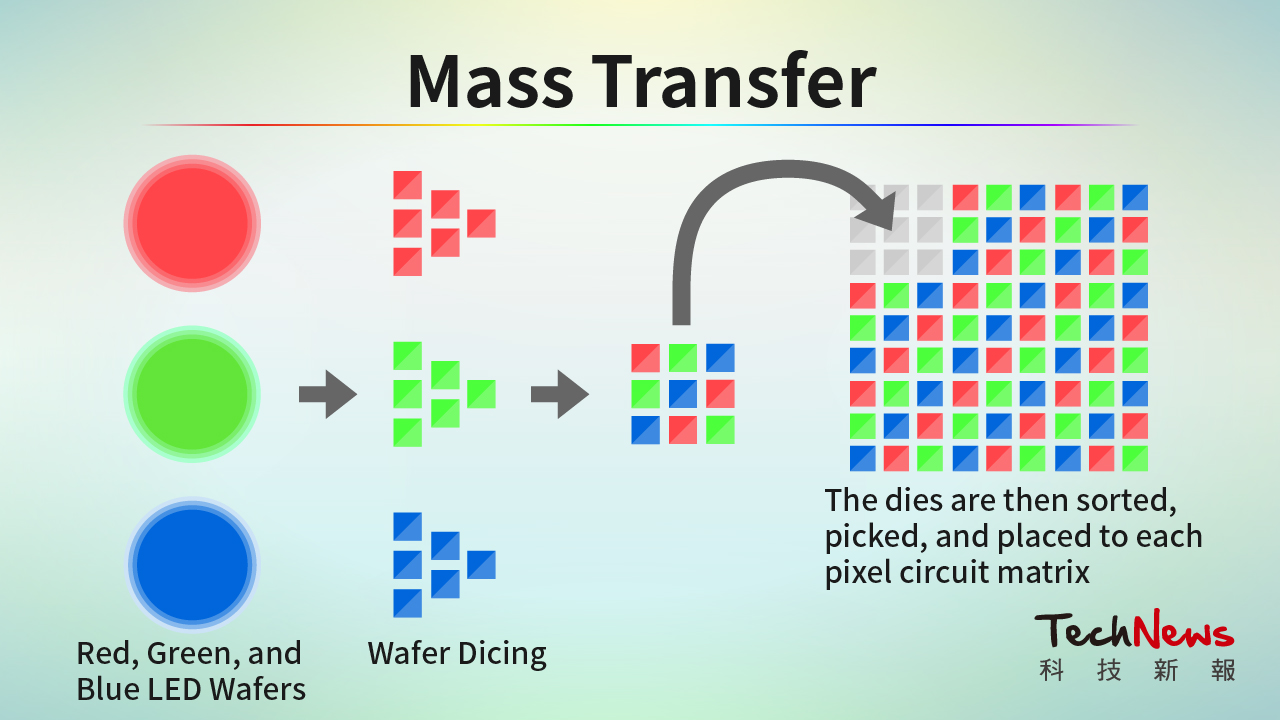

▲ Mass transfer involves transferring LED dies to a circuit matrix completely, which is extremely difficult in practice (Source: TechNews)

In addition to bringing innovation to the LCD industry, Micro LED can be applied to various products, including AR/VR equipment, vehicle mounted monitors, and high-resolution wearables. However, numerous problems remain unsolved for this next-generation technology, including the beginning epitaxy bottlenecks, mass transfer yield, and package testing issues, as well as the later inspection and maintenance challenges. These factors affect whether mass production of Micro LEDs is possible.

Micro OLED, a Next-generation OLED Technology, Can Bring Technological Revolution

Micro OLED has gone viral this year because Apple Inc. worked with TSMC to develop Micro OLED panels. The biggest feature of Micro OLED displays is that—unlike conventional LCD and OLED TVs and high-end smartphones with their screen being built on a glass substrate—the screen is directly mounted to wafers.

Adopting single crystal silicon wafers as their backplane, Micro OLEDs enable the production of thinner, less power consumption, and self-illuminating displays with high luminous efficiency, which are particularly suitable for AR and VR wearables.

The individual size of Micro OLEDs under Apple’s development is allegedly less than 1 inch (2.54 cm), which will be installed in the company’s latest AR products. Nevertheless, the Micro OLED project is still at trial production, suggesting that the market has to wait for a few years before mass production is feasible.

Presently, Sony from Japan, Samsung from South Korea, and BOE from China are all developing technologies using Micro OLEDs, striving for mass production of the components, and realizing their applic

(This article is reposted by TechNews)