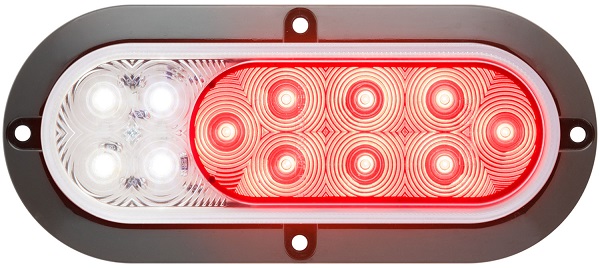

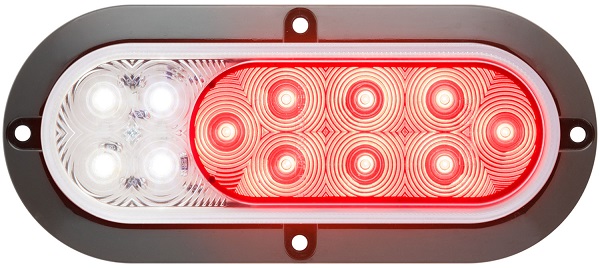

Optronics International, a leading manufacturer and supplier of heavy-duty LED vehicle lighting, is presenting its newly redesigned Fusion LED combination stop, tail, turn and backup lamp in booth 3885 at the 2016 NTEA Work Truck Show in Indianapolis, Indiana. The new Fusion lamp is 25 percent smaller and includes new, optimized, circuitry that hosts both red and white LEDs on a single board, and a patent-pending optical design unlike anything else on the market.

|

Optronics unveils the new automotive LED lihgts, integrating stop, tail, turn and backup lamp in one body. (Optronics/LEDinside)

|

The original nine-inch oval Fusion lamp was introduced at the 2014 Work Truck Show and has since been made available in four-inch round and six-inch oval formats with grommet- and flange-mount versions that fit virtually any standard lighting application. The entire family of Fusion LED combination stop, tail, turn and backup lamps are also being upgraded utilizing the new technology.

The Fusion lamps have been radically redesigned and now employ a more advanced circuit board configuration and LED light projection technology that has a patent pending. An optical bridge helps project red LED light from the red area of the lens to the clear area of the lens during the braking function. The innovative design enables the lamps to use fewer diodes, reduces heat load and lowers the overall lamp cost.

“We have completely reengineered the Fusion LED combination stop, tail, turn and backup lamp and the result is a superior lamp design,” Brett Johnson, president and CEO of Optronics International, said. “Our new Fusion lamps are smarter, more advanced and more economically priced.”

|

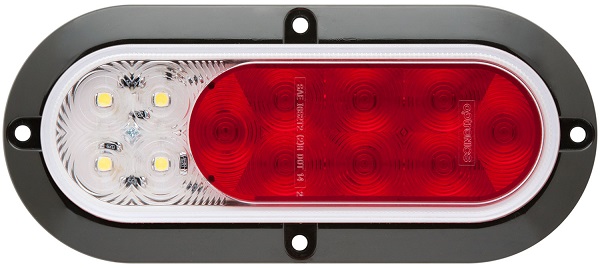

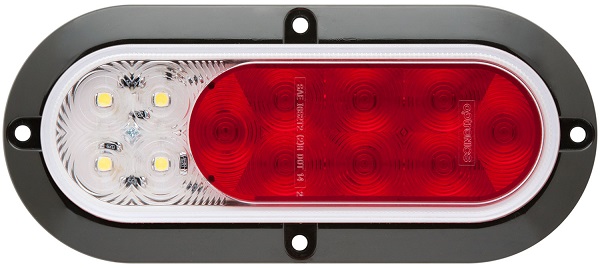

The surface-mount LED lamp requires only a half-inch holde for the lamp's wiring and four mounting holes to accommodate rivets or screws. (Optronics/LEDinside)

|

Before the introduction of the Fusion surface-mount LED combination lamp, vehicles used separate six-inch oval or four-inch round stop, tail, turn lamps and backup lamps. Each lamp needed its own mounting hole, and these holes were made in the vehicle body panels, frame posts, docking plates or gussets. Each lamp hole reduced structural integrity and enabled moisture, road debris and other contaminants to migrate into the cavities behind the lamps.

Mounting the new six-inch Fusion surface-mount LED combination lamp requires only a half-inch hole for the lamp’s wiring and four mounting holes to accommodate rivets or screws. The low-profile, half-inch-thick LED lamp mounts snuggly to the vehicle’s surface while preserving the vehicle’s structural soundness.

Whether flush-mount, grommet-mount or flange-mount, the two-in-one LED lamp concept reduces SKUs and carrying costs and eliminates the need for a separate backup lamp, often still the realm of incandescent bulbs. Fusion LED combination stop, tail, turn and backup lamps provide greater reliability, broader functionality and a much longer service life. The Fusion offers the marketplace two LED lamps for the price of only one.

“Our original Fusion lamps set a new standard in lamp design and functionality, and our new Fusion design continues that legacy,” Johnson said. “We expect customers in work truck, HD, RV and transit vehicle markets to all be thrilled with these new lighting options.”

The new Fusion LED combination stop, tail, turn and backup lamps are expected to be available in the second quarter of 2016. The lamps meet all FMVSS 108 photometric requirements for visibility and safety. Lenses and housings are made of tough polycarbonate material that is sonically welded. The lamps employ a solid-state, surface-mount device (SMD) design that protects their electronics against moisture, shock and vibration. Like all LED products from Optronics, all Fusion lamps come with no-hassle, one-diode lifetime warranty protection that will replace the lamp if even one diode fails.