The new generation of micro light source CSP: Lower cost , Brighter , Smaller heat sink

Smart choice for product designers:

-

Provide an adsorptive technology of powder with Flip Chip Led; the volume is under one tenth of traditional gold-wire bonding LED package.

-

By the “free gold-wire bonding, high arranged density, low thermal resistance, high lumen efficiency“, pulled up the cost and performance.

-

The appearance structure of product can be designed lighter, thinner, and narrower, resulting in greater economic benefits.

-

160 degrees high beam angle without yellow light spot and point light, suitable for thin light fixture and higher beam angle product applications.

-

In the same lumen output, the small area can increase the optical density; offer a bigger power output in the same structure design, so many high optical density designers choose CSP program.

-

Free gold wire, lead frame, and die bond dispensing process, highly reduce the thermal resistance than the traditional LED package, can be resistant to greater current, safety, reliability greatly enhance and wider for product applications.

-

Easy to standardized production or customized production, including optical integrated design.

-

Through the new adsorptive technology of powder, the yield rate of the production is high up to 95%.

-

We are the only one in the world had our own created R&D production machine, and which mass production our adsorptive technology of powder automatically in precision and a high-rated of yield process.

|

|

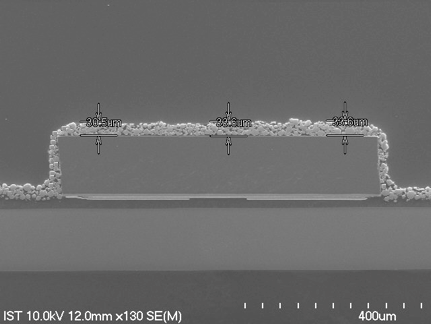

(CSP 1.4mm*1.4mm Larger view) |

|

|

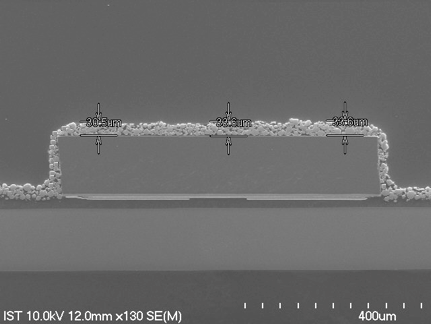

(CSP SEM Sectional view ) |

CSP SGS Reliability Test

-

LM-80

-

TM-21

-

IEC 62471

-

Thermal Shock : -40℃~100℃ (30min~30min),200 cycles

-

High Temp. and High Humidity Operation : 85℃/ 85℃ RH, IF=700mA, 1000 hr

-

Low Temp. Operation : Ta=-30℃, IF=700mA / 1000 hr