Japanese UV LED company Nitride Semiconductors has announced to establish a subsidiary, Micro Nitride, to focus on the developing and manufacturing of Micro UV LED chips for Micro LED display.

Nitride Semiconductors is investing a capital of 100 million yen (US$ 887,300 ) to form the new subsidiary and it will begin operation on November 1st, 2018.

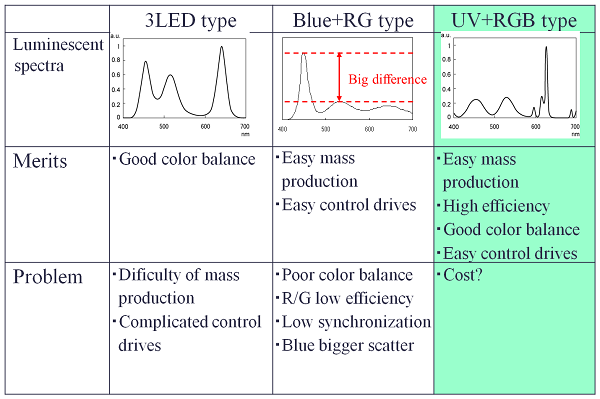

According to Nitride Semiconductors, currently there are two methods to produce Micro LED display. One is 3 LED type which utilizes RGB LEDs and the other way is blue LED excitation type which uses red and green phosphors with blue LEDs. For the 3 LED type, the production of Micro red LEDs is very difficult as its material is fragile. Also, mounting LED chips of different colors with different structures in high density is challenging as the current, voltage and reaction speeds of the RGB LEDs vary. Thus, it is complicated to control each LED chip.

(Fig: Nitride Semiconductors)

On the other hand, the Micro Blue LED excitation method can integrate all mounted LED chips into Micro blue LEDs. As a result, the difficulty of mounting decreases and the current and voltage can also be unified. However, the blue light is emission, whereas the red light and the green light are excitation, so there is expected to be a time lag in reaction speed. Moreover, the color reproducibility is low due to the low luminance of red and green due to blue excitation.

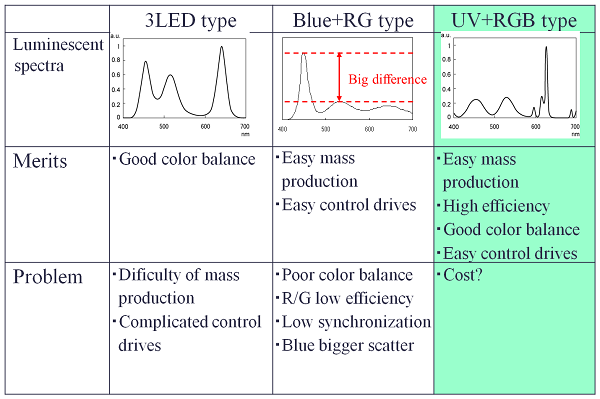

(Image: Nitride Semiconductors)

Nitride Semiconductors uses Micro UV LED with RGB phosphor to solve issues of the methods mentioned above. The company found that the luminous efficiency is doubled when fabricating Micro UV-LED chip with SLS structure in both n and p layer (Patent pending). Since the distance of the diffusion current is short, the light emission recombination increases and the internal quantum efficiency improves.