Australian Cleantech innovator, BluGlass Limited, has announced today that it has been successful in demonstrating the best ever p-GaN light output using its propriety technology, Remote Plasma Chemical Vapour Deposition (RPCVD) on an MOCVD partial LED structure. This result is greater than a 10 fold improvement in LED efficiency over the first p-GaN demonstration data published by the company in December 2012, when the same measuring methodology is applied.

This has been achieved by making significant improvements in addressing the ‘interface challenge’, a key technical hurdle that has been limiting the p-GaN performance demonstration in the past.

|

|

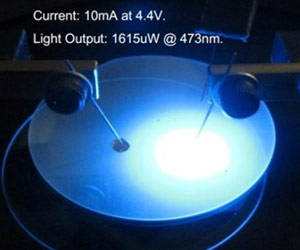

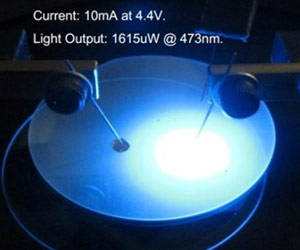

Figure 1: Demonstration of light emission at 473nm, with full width half maximum of 22nm, from a RPCVD p-GaN layer grown on a MOCVD partial structure. |

GaN performance demonstration in the past. These recent breakthroughs are the result of the enhanced plasma system in combination with new process steps which are now yielding continuing performance improvements as the company furthers progress towards its Brighter LEDs milestone

BluGlass Chief Technology Officer, Dr. Ian Mann said “The RPCVD p-GaN based LED performance in the last month has undergone a step change improvement. This has been achieved by focusing on two key aspects – the process steps for initiating the RPCVD p-GaN growth; and in finalising the last layers grown by MOCVD – in effect, making sure the RPCVD and MOCVD steps are compatible. He added,“Following these recent developments, we are confident that the team is on the right path to demonstrate that low temperature RPCVD can enhance the performance of LEDs fabricated solely by MOCVD today.”

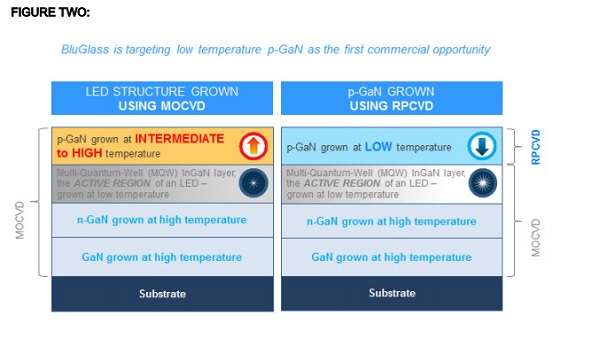

BluGlass is aiming to demonstrate to the industry that an RPCVD top layer (the p-GaN layers) can improve the light output of an LED.

Additionally, the next generation RPCVD System, the BLG-300, is nearing completion and is expected to be growing GaN later this month. This ex-production scale system is a significantly larger system than the current R&D workhorse and will effectively double BluGlass’ research and development capacity. Having multiple RPCVD systems will greatly enhance the team’s capability to address the LED milestones, the scaling of the technology towards 8” wafer deposition and the potential performance advantages of a low temperature CVD process for GaN on silicon.