Tufts University engineers have created a new format of solids made from silk protein that can be preprogrammed with biological, chemical, or optical functions, such as mechanical components that change color with strain, deliver drugs, or respond to light, according to a paper published online this week in Proceedings of the National Academy of Sciences (PNAS).

Using a water-based fabrication method based on protein self-assembly, the researchers generated three-dimensional bulk materials out of silk fibroin, the protein that gives silk its durability. Then they manipulated the bulk materials with water-soluble molecules to create multiple solid forms, from the nano- to the micro-scale, that have embedded, pre-designed functions.

|

|

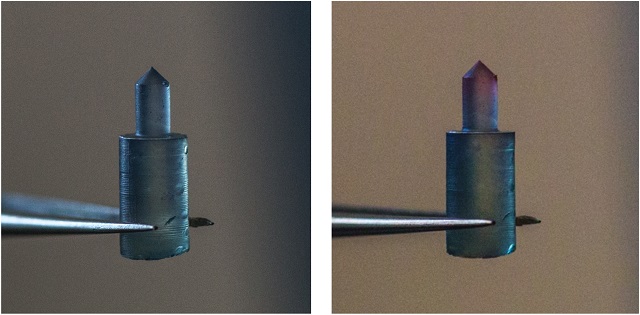

A silk fibroin pin changes color from blue to red when the force applied reaches the material’s yield point. (All photos courtesy of Silk Lab) |

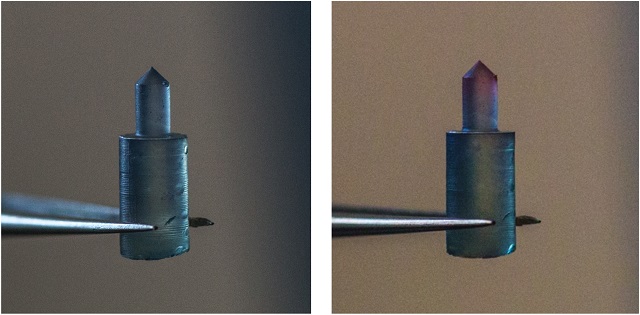

For example, the researchers created a surgical pin that changes color as it nears its mechanical limits and is about to fail, functional screws that can be heated on demand in response to infrared light, and a biocompatible component that enables the sustained release of bioactive agents, such as enzymes.

Although more research is needed, additional applications could include new mechanical components for orthopedics that can be embedded with growth factors or enzymes, a surgical screw that changes color as it reaches its torque limits, hardware such as nuts and bolts that sense and report on the environmental conditions of their surroundings, or household goods that can be remolded or reshaped.

Silk's unique crystalline structure makes it one of nature's toughest materials. Fibroin, an insoluble protein found in silk, has a remarkable ability to protect other materials while being fully biocompatible and biodegradable.

|

|

A silk fibroin screw can be heated to 160 C when exposed to infrared light. |

“The ability to embed functional elements in biopolymers, control their self-assembly, and modify their ultimate form creates significant opportunities for bio-inspired fabrication of high-performing multifunctional materials,” said senior and corresponding study author Fiorenzo G. Omenetto, Ph.D. Omenetto is the Frank C. Doble Professor in the Department of Biomedical Engineering at Tufts University’s School of Engineering and also has an appointment in the Department of Physics in the School of Arts and Sciences.

Paper authors also included Benedetto Marelli, Ph.D., formerly a post-doctoral associate in the Omenetto laboratory and now at MIT; Nereus Patel, formerly a graduate student in the Tufts Biomedical Engineering program and now working for Ecoseal in Australia; Thomas Duggan, visiting artist in residence, Silklab; Giovanni Perotto, Ph.D., Silklab; Elijah Shirman, Ph.D., Silklab; and David L. Kaplan, Ph.D., Stern Family Professor of Engineering, Tufts University. Kaplan also holds Tufts faculty appointments in the Department of Chemical and Biological Engineering, School of Medicine, School of Dental Medicine and Department of Chemistry in the School of Arts and Sciences.

Marelli, Omenetto and Kaplan are listed as inventors in a patent application based on the technology described in the manuscript.

The work was supported by the Office of Naval Research (N00014-13-1-0596).

Benedetto Marelli, Nereus Patel, Thomas Duggan, Giovanni Perotto, Elijah Shirman, David L. Kaplan, and Fiorenzo G. Omenetto, “Directed self-assembly of silk fibroin into bulk materials: Programming function into mechanical forms from the nano- to macroscale,” Proceedings of the National Academy of Sciences, published online Dec. 26. DOI: 10.1073/pnas.1612063114.