This is the first part of Fairchild Semiconductor's five part blog series that will examine LED lighting trends and Fairchild solutions. LED lighting applications fall into three basic input power levels: low-power is less than or up to 20 Watts; mid-power is between 20 Watts and 50 Watts; and high-power is above 50 watts. In the real-world, applications do not always fit nicely in these three buckets, but these power levels align when considering LED driver solutions.

For the purposes of this series, we will be exploring low-power ≤20W applications, especially bulb-type lamp replacements or retrofits, replacement of existing lamps and fixtures, and new construction fixtures.

The global sale of LEDs in lighting was recorded at $4.4 billion in 2013, according to Strategies Unlimited in their last annual report on LEDs (The Worldwide Market for LEDs: Market Review and Forecast 2014). With a forecast calculated annual growth rate of 27.5% from 2013 to 2018, sales are expected to $14.9 billion by 2018. The market potential is large and growing, but is challenging for the LED driver in terms of efficacy improvements (efficacy is the ratio of lumens per watt), lowering the cost, and increasing operating lifetime.

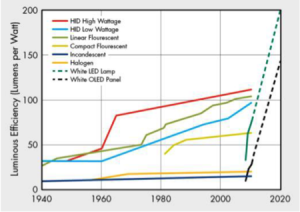

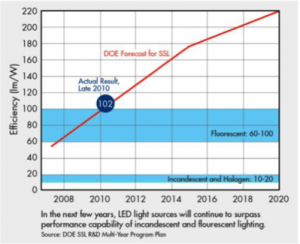

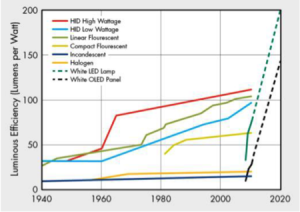

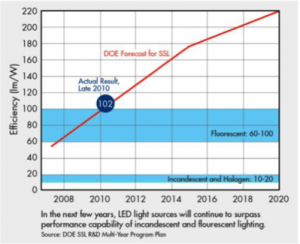

The U.S. Department of Energy (DOE) predicts the potential of high-brightness LEDs to exceed the conventional technologies of today and the past. Fig. 1 and Fig. 2 show the trends of improving efficacy. Efficacy has input power in the denominator of the metric, and the input power and the efficiency of delivering energy to the LED string are related to the LED driver solution. One single driver topology is not optimal across the full range of LED power load possibilities, but there is a minimal set of topology choices to consider that meet the entire spectrum of LED driver development needs.

|

|

|

Fig. 1 Efficacy and Projections of Different Light Sources. (Source: Fairchild) |

Fig. 2 Recent LED Efficacy Performances. (Source: Fairchild) |

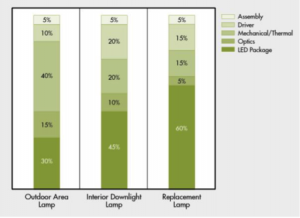

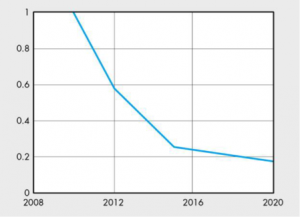

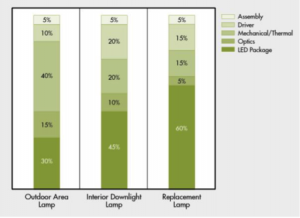

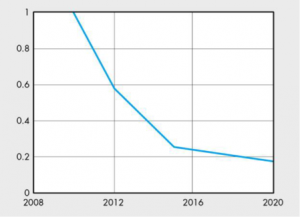

The other common design constraint of a LED Driver is the cost. The DOE approximates today’s costs as shown in Fig. 3; the driver is 10% to 20% of the total manufacturing cost. The total cost target is what the end user sees and becomes the most frequent impediment to the adoption of the LED light solutions, regardless of performance improvements. A presentation at the DOE’s 2011 Solid-State Lighting Market Introduction Workshop suggested the need for cost targets as shown in Fig.4, almost a 50% reduction in cost every four years.

|

|

|

Fig. 3 Approximate Cost Proportions. (Source: Fairchild) |

Fig. 4 Cost Reduction Targets. (Source: Fairchild) |

The operating life is related to the reliability of the LED Driver itself. Reliability is affected by component count, types of components used, and temperature or power dissipated in the LED driver. Reliability can be calculated using a part-count method with the goal to reduce the components used in the driver. Reliability is also affected by operating temperatures; so, while thermal design is important, it is equally important to reduce the power losses associated with LED driver components and topology control method. The trend is to eliminate components like electrolytic capacitors and opto-isolators and integrate features into the control silicon.

In our next installment we’ll talk about LED driver standards and agency requirements.

Please visit our LED resource page to learn about Fairchild’s LED lighting solutions.

(Authors: James Lee, Brian Johnson and Richard Chung of Fairchild Semiconductor.)

CN

TW

EN

CN

TW

EN