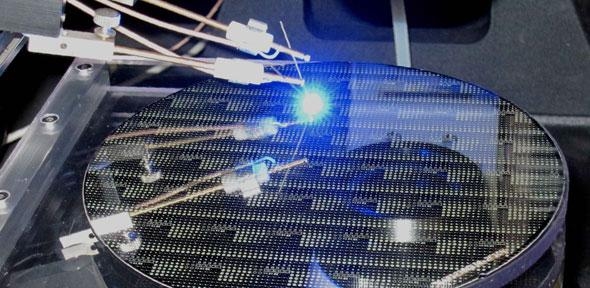

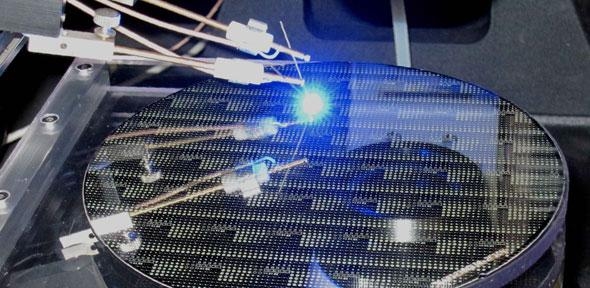

A new facility for GaN, the key material needed to make LEDs, has set up in Cambridge, enabling researchers to expand and accelerate their pioneering work in the field.

GaN-based LEDs are already used in traffic lights, bicycle lights, televisions, computer screens, car headlamps and other devices, but they are too expensive to be used widely in homes and offices.The main reason for this is that they are normally grown on expensive substrates, which pushes up the price of LED lightbulbs.The new GaN growth reactor at Cambridge will allow researchers to further improve a method of growing low-cost LEDs on silicon substrates, reducing their cost by more than 50 percent and opening them up for more general use.

LED technology is already so energy-efficient that it is estimated that the overall demand for electricity would fall by at least 10 percent if every home and business in the UK switched to LED lighting. This would save the UK over £2 billion per year in electricity costs. Further developments planned in the new reactor would result in an additional £1 billion per year electricity savings.What's more, researchers are developing colour-tuneable LED lighting, which would have the quality of natural sunlight, bringing considerable health benefits to users.

What's more, researchers are developing colour-tuneable LED lighting, which would have the quality of natural sunlight, bringing considerable health benefits to users.

University scientists are also starting to investigate the potential of GaN in power electronics, which it is thought could have similarly significant energy-saving consequences. This could cut nationwide electricity consumption by another 9 percent.

The reactor, which is funded by the Engineering and Physical Sciences Research Council (EPSRC), was opened on March 28th by David Willetts MP, the Minister for Universities and Science.

It marks the latest chapter in a decade-long research project to make LEDs the go-to technology for lighting, led by Professor Sir Colin Humphreys in the University’s Department of Materials Science and Metallurgy.