A Japanese research group developed a sheet-like OLED light source that functions even after being crumpled.

The group is led by Takao Someya, professor at the School of Engineering, the University of Tokyo. The minimum bending radius and brightness of the sheet respectively are 10μm and 100cd/㎡. The group expects that the sheet will be used as a new light source for medical and healthcare sensors.

The research group announced a pressure sensor sheet that functions even after being crumpled and is lighter and softer than feather July 25, 2013. For the pressure sensor sheet, it succeeded in forming an array of organic TFTs that constitute an electronic circuit on a film substrate.

\

\

Also, in 2011, the group developed a thin, light OLED photovoltaic (PV) cell. A PV cell is a device that converts light into electricity and, therefore, it is a kind of an optical sensor.

Because of the development of the OLED light source, all the elements necessary for medical and healthcare sensors (organic TFT as a component of an electronic circuit, optical sensor and light-emitting device) became available. And they can be integrated on an ultra-thin sheet, the group said.

For collecting biological information such as the amount of oxygen in the blood, devices made by combining a light source and light-sensitive detector are widely used. Therefore, the research group expects that the new OLED light source will be used for medical and healthcare wearable devices that use light as a probe to collect a variety of biological information.

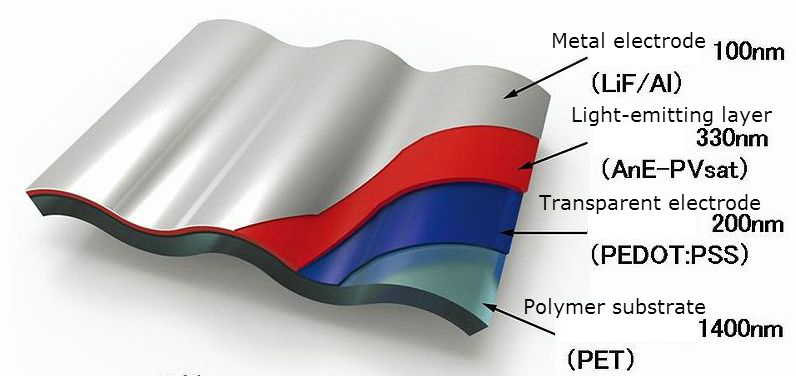

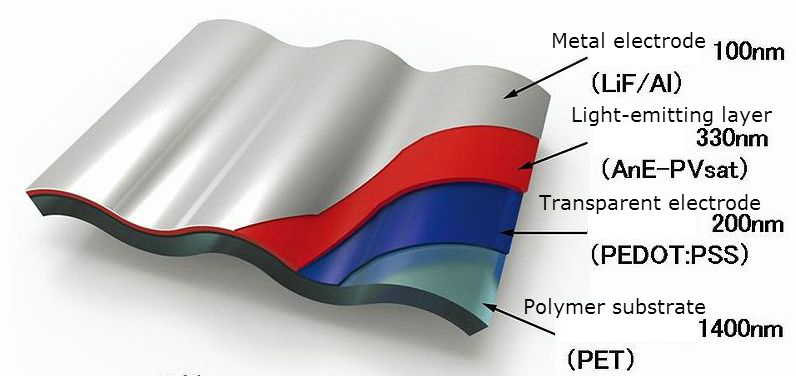

The sheet-like OLED light source has a mass of 3g/㎡, which is as light as the sensor sheet announced July 25, 2013. With a thickness of 2μm, it can be flexibly bent. By establishing a technology to directly accumulate OLED elements on a 1.4μm-thick plastic film substrate, the group developed the light, soft OLED light source.

This time, the research group made improvements to a technology for manufacturing OLED elements and constituent materials. To directly form OLED elements on a plastic film substrate, which tends to be damaged in the manufacturing process, the group eliminated ITO electrodes, which require a high-energy film-forming process using plasma. Instead, it used a conductive polymer (PEDOT: PSS) that enables to form a film with a spin-coating process, which requires a low temperature and low energy, for positive electrodes.

The PEDOT: PSS has been used as a material for hole-injection layer. But the group found that it can also be used for the positive electrodes of the OLED elements of light sources.

The group conducted the research in cooperation with a research team led by Siegfried Bauer and a team led by Niyaze Serdar Sariciftci. They are professors at Johannes Kepler University of Linz in Australia.

\

\