With the increasing improvement of process and equipment accuracy of major packaging plants, the chip size of Mini

LED applications has gradually evolved from 5x9mil to today's 3x5mil, even smaller. The reduction of chip size means that more LED chips can be arranged in the same unit area of display or backlight unit, and higher requirements are put forward for chip mounting. At the same time, higher requirements are put forward for chip mounting.

First of all, the most significant change is that the pad size of the PCB becomes smaller, and the corresponding stencil opening also becomes smaller. The smaller the opening, the higher the requirements for the printing effect of the solder paste, and the stricter the control of the process.

Three factors affecting solder paste printing: Stencil, squeegee, solder paste.

Collectively referred to as 3S factors. According to SMT source research, nearly 65% of soldering defects come from solder paste printing defects.

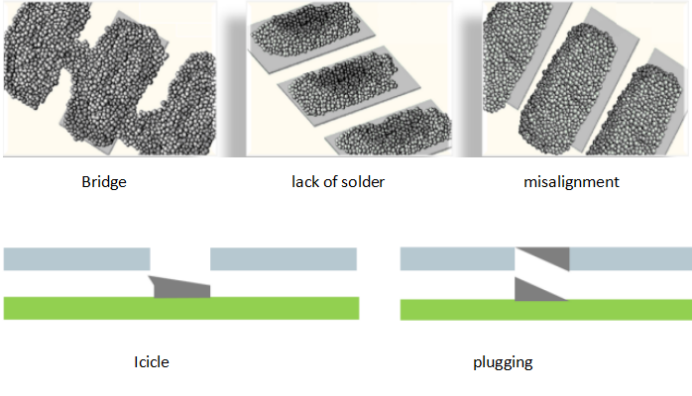

The poor performance of printing is concentrated in: bridging, lack of solder, misalignment, plugging, icicle, etc.

Correct understanding of stencil, squeegees, and solder paste is the key to sustaining good print performance.

Stencil composition: generally composed of mesh frame, stainless steel sheet, meshwork, meshwork glue.

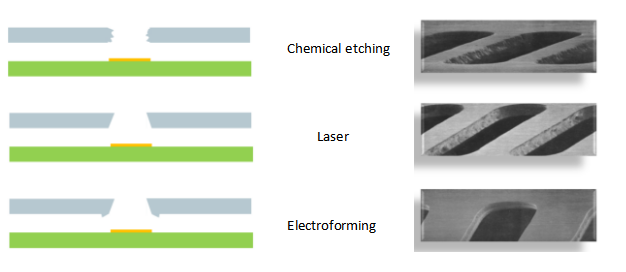

Commonly used Stencil can be divided into three categories according to the production process: chemical etching, laser, and electroforming.

1)Chemical etching: Using chemical liquid etching process, one-time molding, low cost, rough inner wall of the opening, low position accuracy, and not environmentally friendly.

2)Laser: It is formed by laser cutting and is the most commonly used Stencil in the industry at present. It is directly produced by data files which reduces the production error and has high precision, but it needs to be cut one by one, and the speed is not fast.

The inner wall of the opening is relatively smooth, and the opening is small at the top and large at the bottom, which helps to release the solder paste. At present, the vast majority of SMT applications use this process to make stencils.

3) Electroforming: It is a metal forming process by depositing nickel metal on the base plate or template to form a metal layer.

The electroformed Stencil has a smooth wall and an inverted trapezoidal structure, which achieves the best solder paste release effect at present. In addition, due to the characteristics of the electroforming process, a ring protrusion slightly higher than the thickness of the steel sheet is formed at the edge of the hole. The solder paste is equivalent to a "seal ring" when printing. This seal ring is conducive to the close fitting of the steel mesh with the bonding pad or the solder mask, preventing the solder paste from leaking to the outside of the bonding pad. The disadvantage is that the cost is high.

As shown in the figure below:

In the printing process of Mini LED, as the openings are getting smaller and smaller, the roughness of the hole wall directly affects the release of the solder paste after printing. Therefore, most customers use the laser to open the holes and then carry out the electro-polishing process to polish the hole walls of the Stencil. Grinding to further improve the opening hole wall and make the hole wall smoother.

At the same time, the stencil manufacturer has added the nano coating process, which makes the solder paste not easy to attach to the stencil, reduces the frequency of stencil cleaning and the probability of blocking holes, and further improves the production efficiency and printing quality.

1. There are two common types of Squeegee: rubber or polyurethane Squeegee and metal scrapers. At present, most printing processes adopt stainless steel scraper. When the scraper angle is 45-60 °, the solder paste has good rolling characteristics which is helpful for tin laying.At the same time, due to the metal material, the scraper is not easy to deform under high pressure, and the solder paste will not be dug out from the opening, resulting in less tin.

Precautions during the use of Squeegee:

1) After printing, clean the hard solder paste on the surface of the squeegee and the gap between the clamps. After cleaning, place it in the fixed area to prevent people from bumping or scratching.

2) It is required to maintain the squeegee every month to confirm whether the scraper is damaged or deformed and ensure the printing performance.

2. Solder paste is composed of solder powder and flux. Solder paste and flux directly affect the printing rolling and demoulding effect of the solder paste on the stencil.

1) Rolling effect: more than 80% of the components in the solder paste are solder powder, the particle size concentration & sphericity of solder powder is directly affected. Jufeng applies ultrasonic multistage atomization technology to make the particle size concentration of solder powder exceed 80% of the IPC requirements, reaching more than 90%. At the same time, multistage atomization removes abnormal balls to ensure the sphericity of solder powder.

2) Demoulding effect: The solder paste applied by Jufeng to Mini LED adopts a unique flux formulation system. A high-efficiency mold release agent is added to the system, which can effectively break away from the mesh during printing and mold release and reduce printing defects.