In a 25,000-square-foot commercial office on the Rensselaer Technology Park campus in Troy, N.Y., scientists from the Lighting Research Center (LRC) at Rensselaer Polytechnic Institute are making plans to install LED lighting with fixture-integrated and network-connected lighting controls. The controls are being tested in a broad-based field evaluation to compare and quantify the additional benefits that connected lighting systems offer to users. LRC research scientists will investigate everything from ease of installation to user satisfaction. This is just one of many projects that the LRC’s Solid-State Lighting Program has undertaken to expand its research capabilities into new fields where solid-state lighting (SSL) can provide benefits.

In the past year, the LRC has set a course to support the SSL industry through research that shows the value of lighting beyond energy savings. Embracing the trends toward customization and data analytics, SSL research is now evolving to include new developments such as the Internet of Things (IoT) and 3D printing—areas where the lighting industry can both find and add value. The SSL Program’s multidisciplinary researchers will be focusing their efforts in the areas of lighting systems and components research, data analytics, field demonstration and market transformation activities, education, and industry collaboration.

“The idea is to avoid the commoditization of solid-state lighting by asking how we can use lighting for more than just illumination,” said Professor Nadarajah Narendran, Ph.D., the LRC’s director of research and head of the SSL Program since its inception in 2001. “LED fixtures and lamps have mostly matured, so now there is a push toward exploring how LED lighting can be customized and how to use lighting to gather information that provides greater value to both producers and users.”

|

|

Connected LED lighting. (All photos courtesy of LRC) |

Connected lighting

As just one piece of the extensive IoT field, connected lighting is defined as the connection of lighting, controls, and sensors to a local network that can be monitored and controlled, either wired or wirelessly, through a dashboard accessed by a computer, tablet, or smartphone. The lighting system may or may not be connected with other building systems, such as HVAC and security systems. With connected lighting, the lighting system is automated based on predetermined conditions, such as those defined by timers, and on sensing information, such as that gathered by occupant and daylight sensors. While these devices have existed for some time, until now there was no way to remotely control and override the commissioned settings on the fly for one fixture at a time. Connected lighting systems are new and still evolving, and as such are mostly untested and have not been compared in the field with traditional lighting controls including autonomous fixture-integrated sensors. This has prompted the LRC with support from the New York State Energy Research and Development Authority (NYSERDA) to evaluate how this networked technology might work in the real world. In this two-year project, the LRC SSL team will evaluate what types of networked and fixture-integrated systems work best for different types of spaces and will produce results and best practices guides for both purchasers and manufacturers.

Another potential feature of connected lighting that the LRC is exploring is the ability for remote monitoring, whereby data is gathered to monitor the “health” of the lighting system. Such capabilities provide building managers with the benefit of early warnings that allow for timely scheduling of maintenance and replacement of lighting fixtures, avoiding burned out lighting that can leave negative effects and impressions.

Since last year, the LRC has been investigating a methodology that allows for the real-time prognostic health monitoring of an LED lighting system using wireless data transfer to a smart device. The study aims to validate a data-driven approach that utilizes current and historical data statistically and probabilistically to detect anomalies in product behavior and estimate the remaining useful life of a lamp or device. This includes analyzing wireless methods that can best communicate and map luminaire location, and determining sensor communication protocol requirements for reliable transmission of sensor data to a monitoring system.

Beyond illumination control and monitoring, connected lighting systems can be used to gather data about anything that can be sensed, from energy usage to occupancy to ambient temperature. The lighting fixtures become the infrastructure carrier for the non-lighting-related sensors, and the data gathered is provided through the same monitoring dashboard.

“Overall, connected lighting systems allow for streaming of real-time data, generating intelligence, and enabling users to make better decisions, providing value beyond energy savings,” said Narendran.

|

|

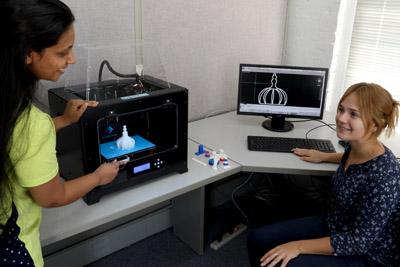

Customized 3D printing. |

Customization with 3D printing

3D printing, also known as additive manufacturing, allows objects of almost any shape or geometry to be manufactured from digital model data. One value of 3D printing for SSL is the ability to design custom lighting fixtures that match the architectural features of a building and then “print” or manufacture them onsite for quick installation. Narendran noted that the custom aspect of 3D fixture printing has many attractive qualities.

“Last summer, one of our interns experimented with 3D printing of decorative OLED fixtures, where she created modular fixture templates that attached to an OLED panel and could be swapped out easily,” said Narendran. “Each template provides a different aesthetic look to the OLED fixture, giving homeowners or decorators the flexibility to change the look of a space as easily as moving furniture.”

3D printing also can be beneficially utilized at the fixture component level. LED lighting typically requires heat sinks to draw heat away to maintain life and light output. With 3D printing of fixtures, heat sinks can be designed to be part of the fixture envelope rather than attached afterwards, which would reduce the fixture’s bulk size and cost and improve its visual appeal. Currently, the LRC team is examining how fixture materials can be customized with the right amount of directional thermal conduction properties, allowing for the production of custom SSL fixtures within the additive manufacturing process.

To learn more about the research activities of the LRC’s Solid-state Lighting Program, visit www.lrc.rpi.edu/programs/solidstate/index.asp.