One critical issue of Micro LEDs is that their luminous efficiency decrease as their dimension shrink, leading to increasing problems in inspection and repair. Technology developers thus try to improve Micro LED efficiency at the phase of epitaxy wafer production. A group of researchers from UCSB, including Nobel winner Shuji Nakamura, recently published a paper describing the method of fabricating high performance InGaN Micro LED with epitaxial tunnel junctions (TJs Micro LEDs).

Published in Optics Express, the paper, titled “Size-independent Low Voltage of InGaN Micro-light-emitting Diodes with Epitaxial Tunnel Junctions Using Selective Area Growth by Metalorganic Chemical Vapor Deposition,” demonstrated the results of TJs Micro LEDs through selective area growth (SAG) by MOCVD.

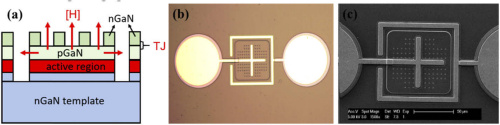

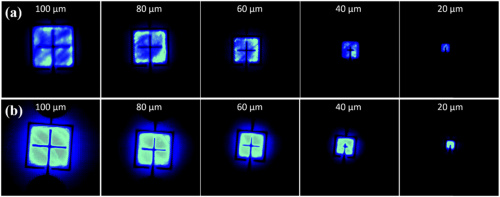

(Schematic structure of GaN TJ µLEDs utilizing SAG; image: Li et al. 2020)

InGaN TJs LEDs deliver higher efficiency and lower efficiency droop. Moreover, when produced by MOCVD, the production can be easily scaled up for mass production. However, the growth of TJs LEDs could be challenging. The research team of UCSB used selective area growth to overcome the current issue of TJs Micro LEDs.

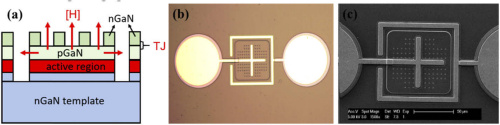

The group used standard industry blue InGaN LEDs epitaxial wafers grown on patterned sapphire substrate (PSS) with an emission wavelength at ∼440 nm for the TJs regrowth. A graphic of using SAG to grow TJs Micro LED was demonstrated. Comparing to TJs Micro LED grown without SAG, SAG TJ Micro LEDs showed luminous uniformity in in different sizes in 20, 40, 60, 80 and 100 μm. SAG TJ Micro LED also showed reduced forward voltage with improved efficiency.

(Luminous microscope images of (a) reference TJ µLEDs without SAG and

(b) TJ µLEDs utilizing SAG. The devices’ sizes were varied from 100×100 to 20×20 µm2.; image: Li et al. 2020)

The scientists demonstrated the lowest forward voltage of GaN-based Micro LEDs with epitaxial TJs grown by MOCVD. The forward voltage in the TJ µLEDs grown by SAG was independent on sizes and was low at 3.24 to 3.31 V at 20 A/cm2, exhibiting a significant improvement over the common MOCVD grown TJ µLEDs. Moreover, an enhancement of the output power and EQE of the packaged devices was observed. These results suggest that SAG is a promising technology for the realization of TJ grown by MOCVD.

Seize the opportunity to learn more about the cutting edge display technologies Micro LED and Mini LED by joining us at 2020 Micro LED Forum. Worldwide experts will demonstrate the latest technology innovations and the key points of commercialization for the technologies. Early bird discount available now!