Which scientist does not dream of the possibility to utilize waste in a useful way? One of these superfluous waste materials is carbon dioxide. So why not use the climate killing carbon dioxide for producing high-quality products? The process needed for this is one of the oldest and most effective in the history of our planet: photosynthesis.

|

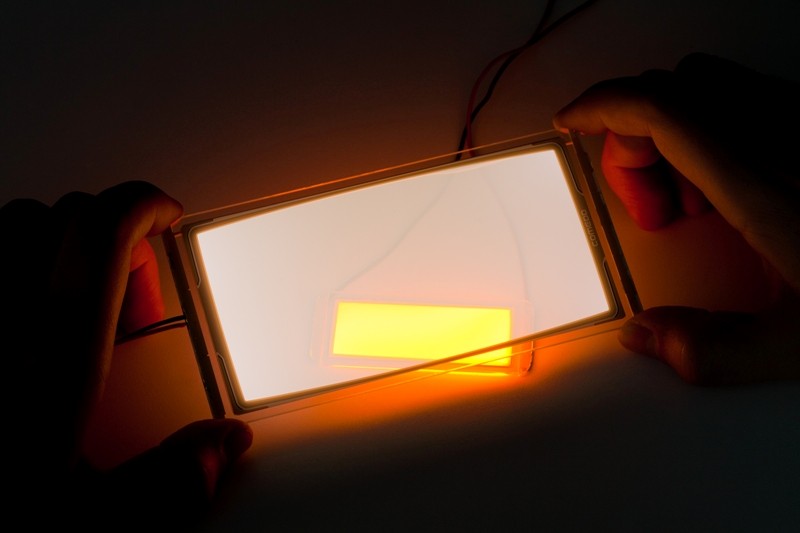

OLED lighting panel (photo courtesy: Fraunhofer COMEDD)

|

Researchers of the TU Dresden and Fraunhofer COMEDD are developing bioreactors for the cultivation of micro algae by using organic light-emitting diodes (OLED) in a worldwide unique pilot project funded by the Saxon State Ministry for Higher Education, Research and the Arts (SMWK).

Dr. Karsten Fehse, project manager at Fraunhofer COMEDD is delighted: “With the help of OLED lighting, salts and water the carbon dioxide will be absorbed by micro algae and transformed into a wide range of high-quality products, e. g. proteins, dyes, cosmetic or pharmaceutical substances.“

|

|

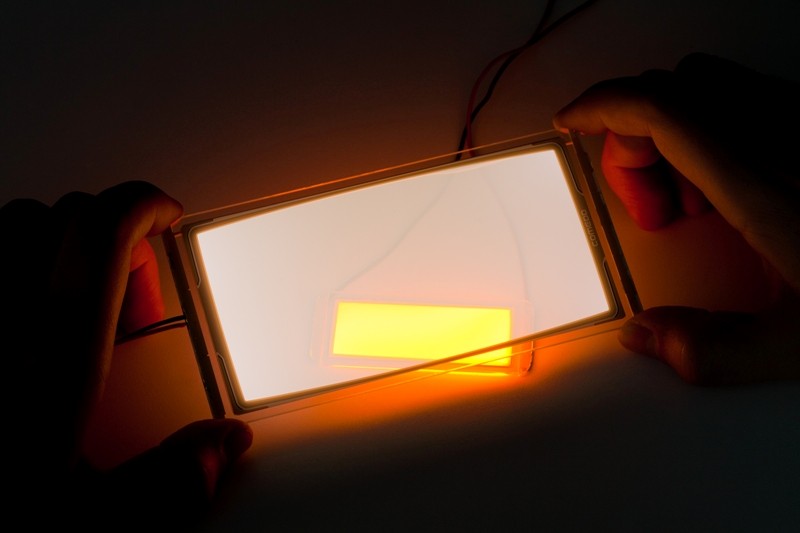

Transparent OLED (photo courtesy: Fraunhofer COMEDD) |

The researchers of the Institute of Food Technology and Bioprocess Engineering at the TU Dresden and Fraunhofer COMEDD are working on a method to make this versatile process more effective by providing the necessary lighting energy to the micro algae by means of organic semiconductors, so-called organic light-emitting diodes (OLED). These innovative area light sources can be produced in almost every shape and are characterized by their flat design (less than 200 nm thick). Thus they can be integrated into a variety of substrates such as glass, metal or foils and enable the bioprocess engineers to realize novel reactor models beyond the previous geometrical borders.

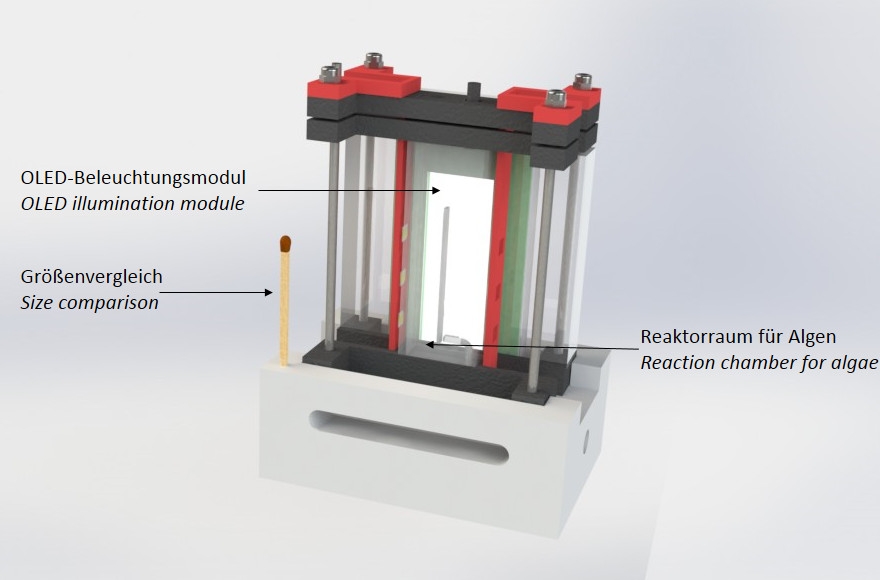

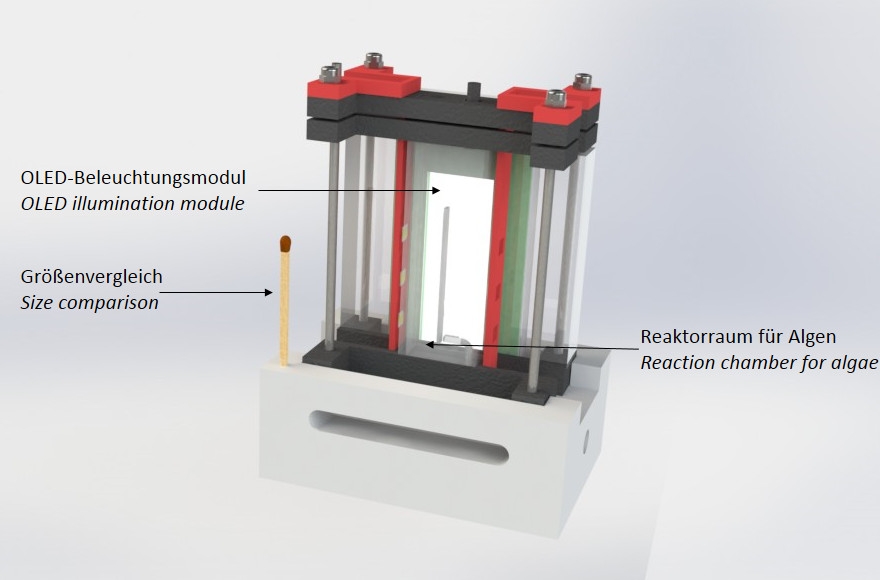

Within the current project a reactor system will be developed which combines OLED technology and bioprocess technology by phototrophic microorganisms and thus provides the basis for novel and innovative algea reactors. These innovative reactors are no large stainless steel boilers, but miniaturized plastic photobioreactors which have the size of a cigarette packet. The small all-rounders provide information about procedural process parameters, the physiological condition of the algea cells and the development of the target products – and all of this by means of optical measurement technology. Due to the extensive process information the new technology helps on optimizing biotechnological processes with phototrophic organisms in a fast and sustainable way.

|

|

Bioreactor with OLED lighting (schematic) (photo courtesy: Fraunhofer COMEDD) |

Felix Krujatz, researcher at the Institute of Food Technology and Bioprocess Engineering at the TU Dresden summarizes: “Due to this next generation of reactor technology we hope to gain a deeper insight and new findings concerning the behavior of micro algea in biotechnological production processes.”

The joint research project is funded by the Saxon State Ministry for Higher Education, Research and the Arts with 670,000 Euro under the funding number 4-7531.60/29/16 and has a duration of 20 months. The project partner thank the SMWK for the funding of the project.

CN

TW

EN

CN

TW

EN