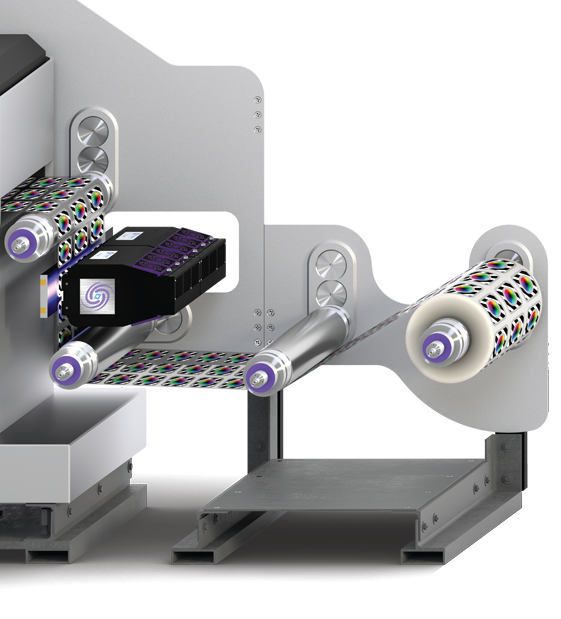

Phoseon Technology is revolutionizing the narrow-web printing industry by combining flexography, which has been used for printing for more than a century, and UV-LED curing technology, which Phoseon first introduced to the narrow-web industry in 2009.

Phoseon this week released two new products to further advance the use of UV-LED curing for narrow-web applications: the FirePower FP601 and FireJet FJ601.

Phoseon’s technology uses UV LED light to rapidly set, or “cure,” ink used in printing, resulting in a higher quality product without the use of solvent-based inks.

|

|

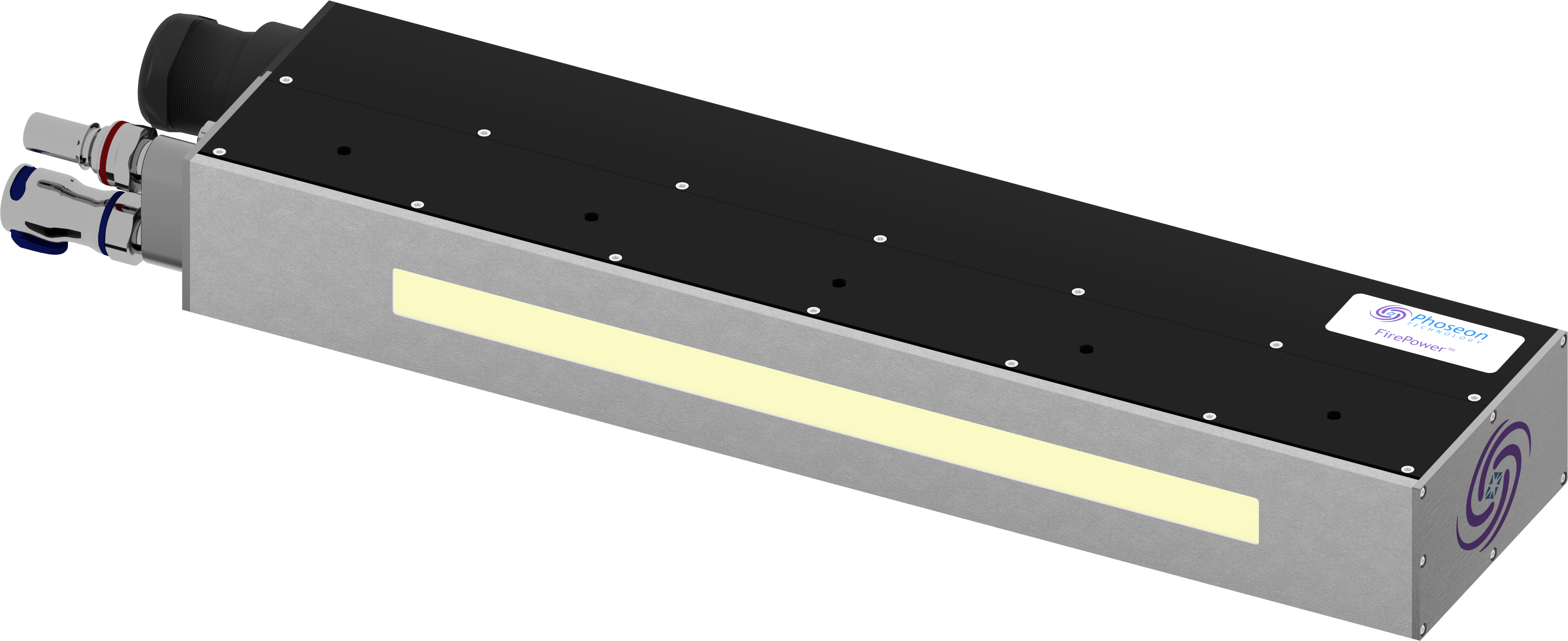

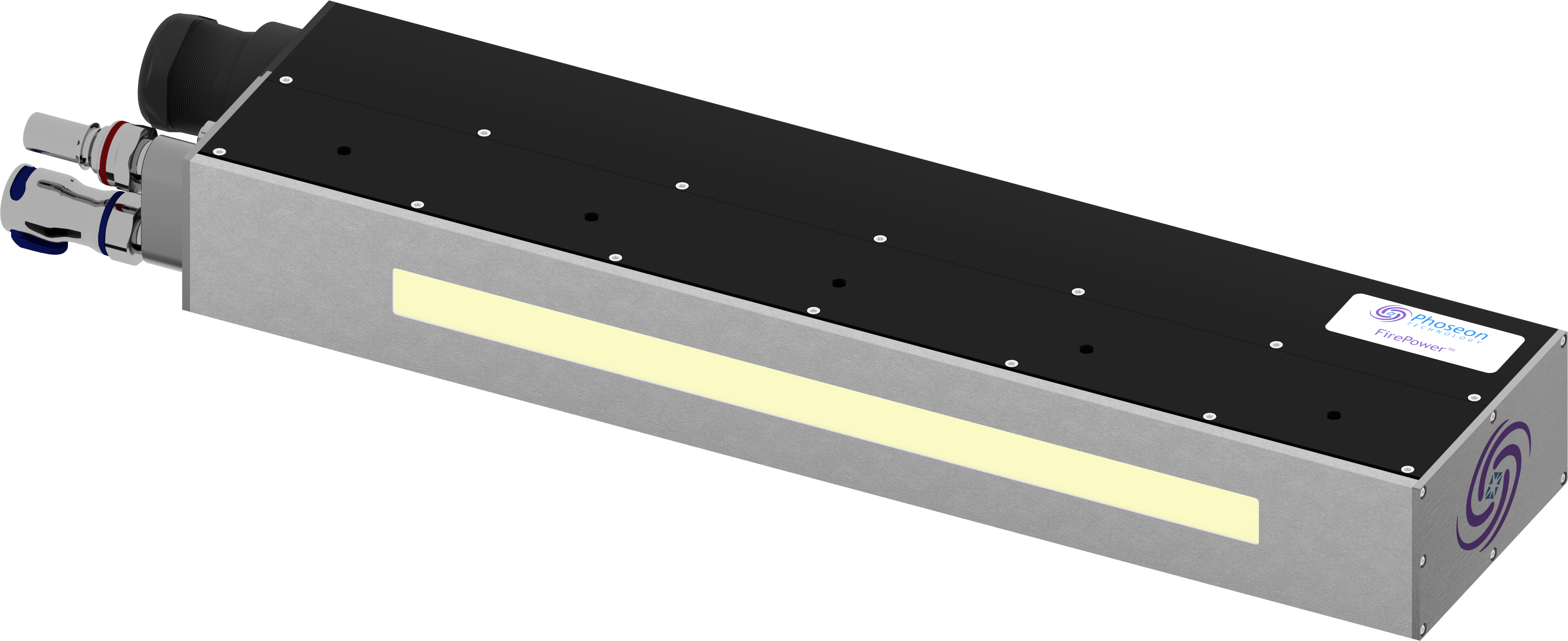

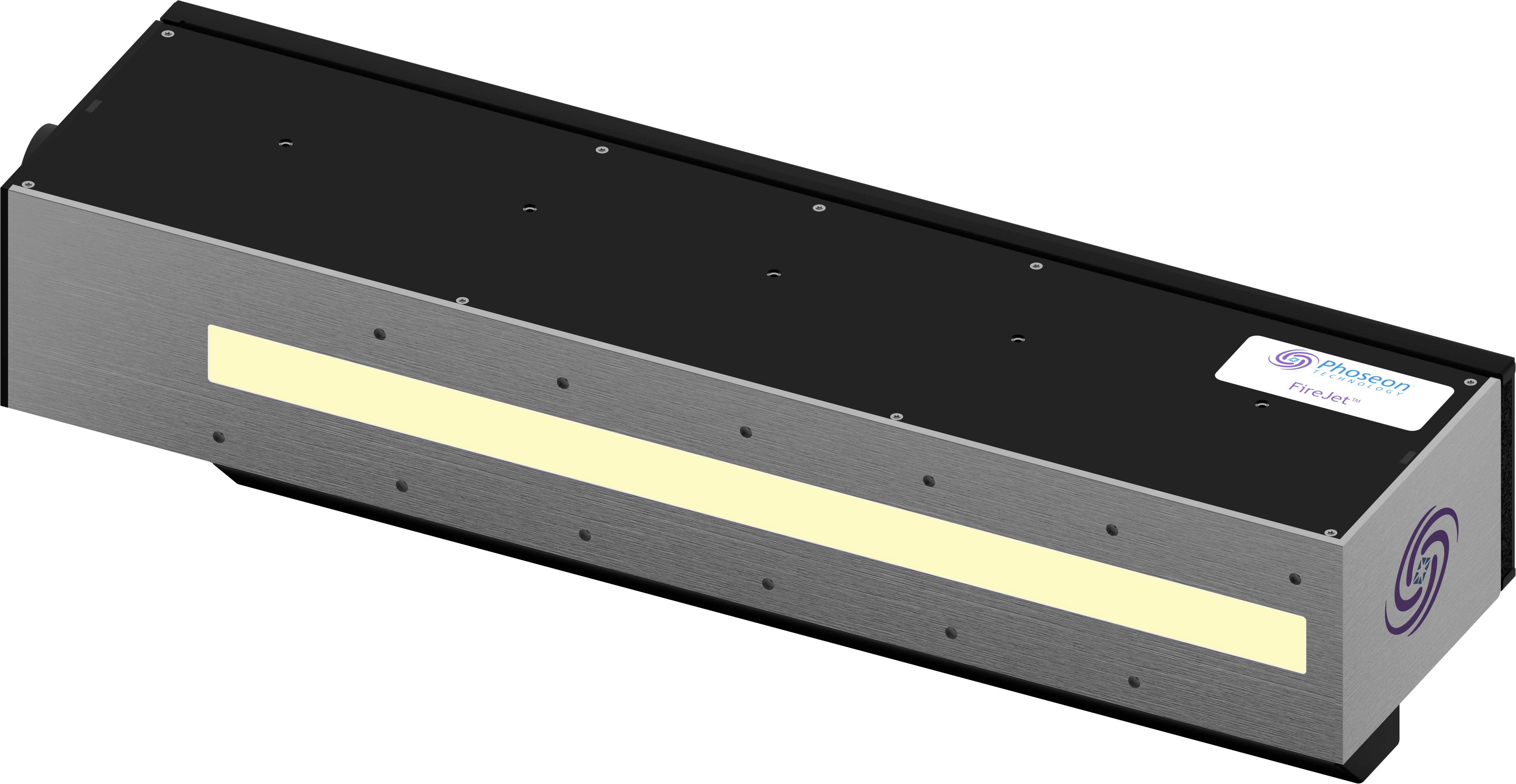

Phoseon's new FirePower™ FP601 provide water-cooled LED curing solutions for narrow-web printing, along with a wide array of existing solutions for the label market. (Image: Phoseon Technology) |

Flexography utilizes a flexible relief plate — a modern version of letterpress — to print on nearly any type of material, from paper to plastic to metallic film. Unlike solvent or water based flexographic inks, UV inks dry almost instantly when exposed to UV light, resulting in a sharp and colorful image. With a UV-LED solution, Phoseon is enabling converters to enjoy the benefits of UV curing without the typical costs and hazards of operating an arc lamp to produce the UV light.

“UV LED allows you to complete a wider range of print jobs with higher quality, faster and more consistently,” said Jennifer Heathcote, regional sales manager at Phoseon Technology.

Narrow-web printing — a term primarily pertaining to a printing width under 30 inches — is often used for printing labels, plastic bags and flexible packaging. In addition to higher quality, UV LED curing for flexographic printing allows for better process control, less waste and the ability to run presses faster than with traditional narrow-web printing methods.

|

|

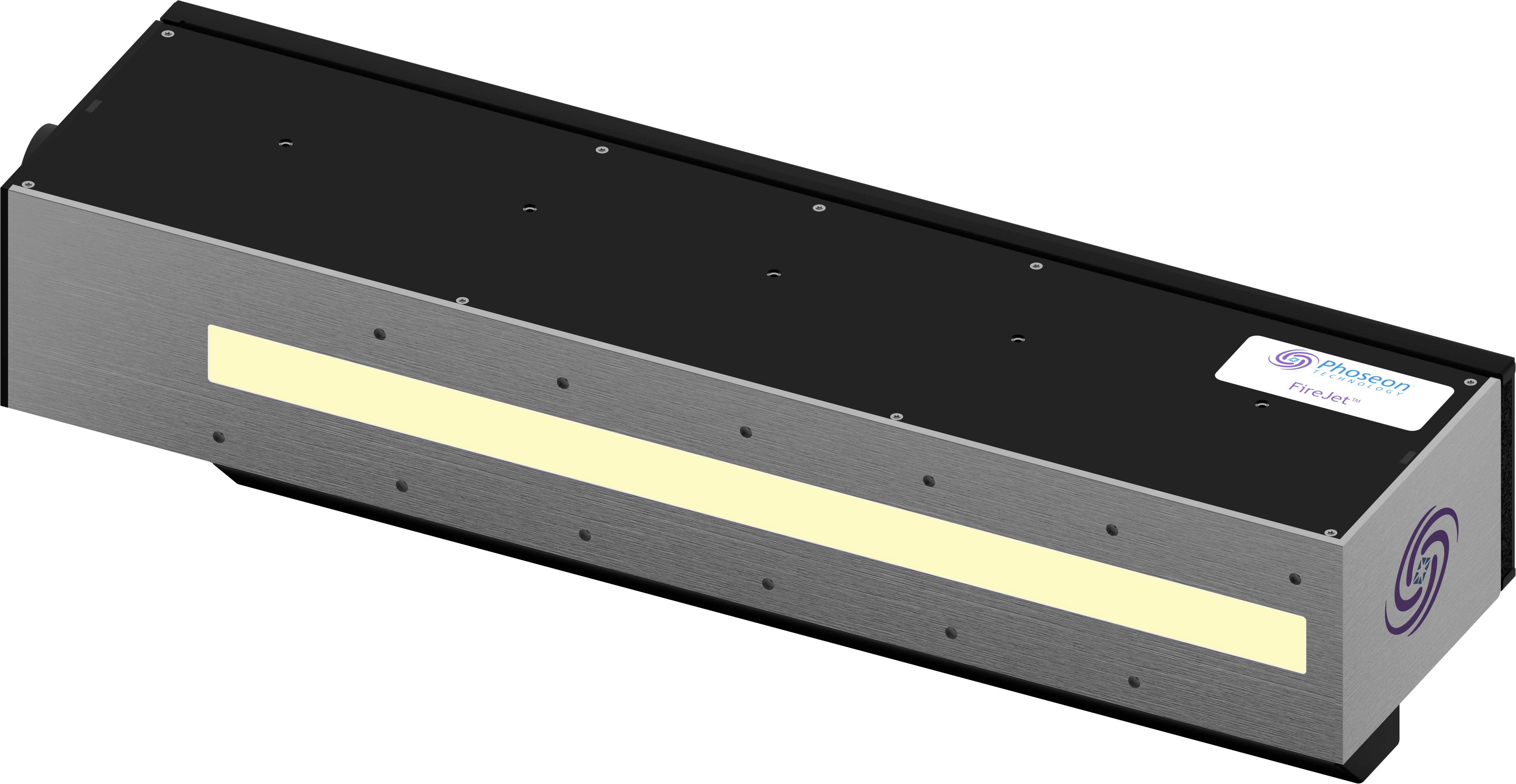

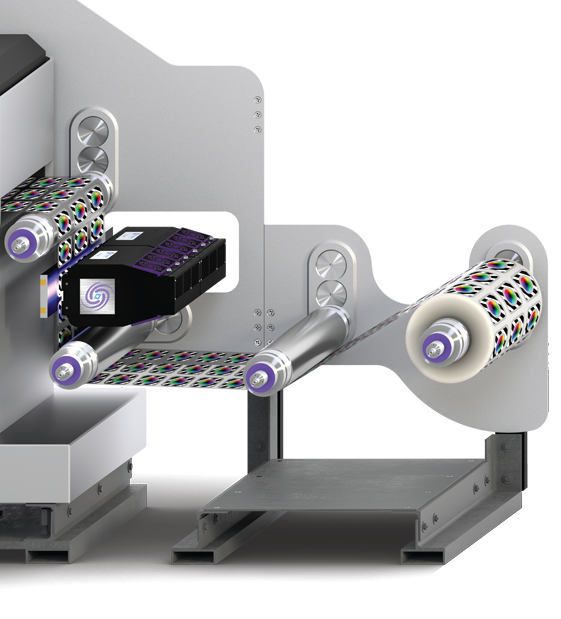

Phoseon’s news The FireJet™ FJ601, used for LED curing during narrow-web printing applications, simplifies retrofits with a self-contained air-cooled design that eliminates the need for air-extraction systems or water-cooling systems. (Image: Phoseon Technology) |

“UV LED flexography uses raw chemistry that flows like a liquid. When the UV LED cures that liquid, it forms a long, continuous bond,” said Sara Jennings, senior technical marketing engineer dedicated to flexographic and narrow web applications at Phoseon Technology. “What you apply to the surface is what you end up with; there is no deterioration, bleeding or fading.”

Narrow-web printing applies ink in layers by color, which, when using solvent- or water-based inks, requires slow and precise drying times to get sharp images; any variation results in blurring or “bleeding” of the color that blurs the image or print. Creating a consistently sharp image is challenging on a porous material like paper, but it is compounded when printing on a nonporous surface like poly plastic. Traditional UV inks provide consistent color, but due to the extreme heat of the arc lamps, it limits the types of materials that can be used.

UV LED flexography excels in areas that are in high demand today, from printing on plastic yogurt containers to labels found on numerous consumer items, such as bottled water to snack bags. In addition to its quick-drying capabilities, UV LED curing creates little heat to transfer to, and potentially damage, the printing surface. “That’s a critical benefit, especially when printing on plastics often used for packaging,” said Heathcote.

|

|

Phoseon Technology has pioneered the use of LED technology for UV curing applications, including narrow-web printing. (Image: Phoseon Technology) |

In addition to standard label and shrink-film jobs, the stable, consistent output of the UV LED system enables converters to confidently run food- and medical-safe processes using LED low-migration inks.

Heathcote notes that while there are upfront costs to begin, or switch to, UV LED curing for narrow-web printing, companies often quickly recoup their investment. UV LED curing has no moving parts, virtually eliminating down-time for maintenance and repairs, and UV LED bulbs last longer and require less energy to operate than traditional arc lamps, reducing operation costs and energy usage by up to 70 percent. In addition, because UV LED curing does not contain mercury, which is used in arc lamps, it is safer for the environment and workplace.

The FirePower FP601 is a water-cooled solution with advanced control features using a Modbus interface and a high intensity output for the fastest possible cure speeds. The FireJet™ FJ601 simplifies retrofits with a self-contained air-cooled design that eliminates the need for air-extraction systems or water-cooling systems.

In addition to narrow-web printing, Phoseon Technology’s UV LED technology also is used in a wide range of other applications, such as wide-web and decorative printing, manufacturing wood, and curing wood and filament coatings.

CN

TW

EN

CN

TW

EN