Stanley announced that it has confirmed high effectiveness of virus inactivation of SARS-CoV-2 by using its 265nm UVC LED, following a testing result in collaboration with Yamaguchi University. The company also reported its establishment of an integrated production system for UVC LED.

Stanley and professors at Laboratory of Veterinary Microbiology, Joint Faculty of Veterinary Medicine, Yamaguchi University, jointly tested the UVC LED of Stanley on deactivating SARS-CoV-2 virus. They put 10 ml of virus solution (5 x 10⁵ PFU/mL) in dishes and exposed the dish with UVC light delivered by a 265nm UVC LED which Stanley began mass production since July 2020. The results showed that the UVC LED achieved an inactivation rate of 99.9% for SARS-CoV-2, when the UV Dose is 5.1mJ/cm2.

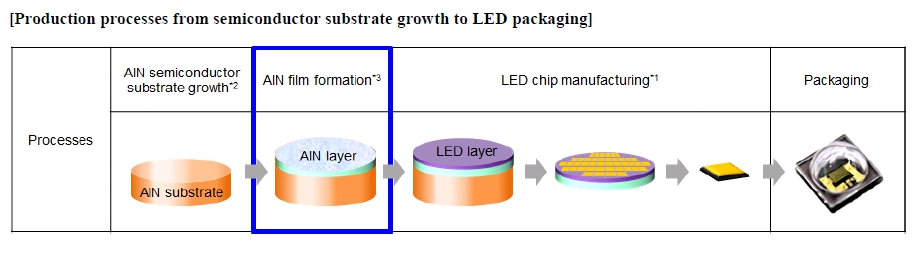

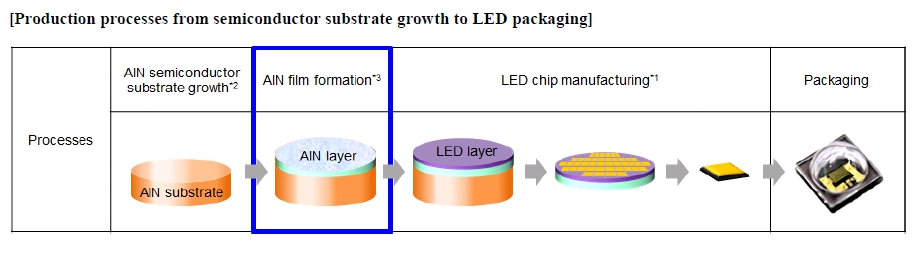

In addition, Stanley shared its new approach of UVC LED production. The company developed an integrated production system that covers every stage of UVC LED production, from semiconductor substrate growth to LED packaging, within the Stanley Group. The method enables Stanley to manufacture UVC LEDs with a wavelength of 265 nm to offer advanced performance for disinfection.

(Image: Stanley)

Stanley possessed the LED chip manufacturing processes and AlN semiconductor substrate growth processes based on its patents and know-how. The company is able to develop AIN films with its in-house technology which serve to increase output of the LED. These capabilities also enable the Group to handle all of the production more cost effectively.

Stanley is expanding this business with the aim of applying the highly effective 265 nm UVC LEDs for various disinfecting applications covering surface disinfection, air and water purification to prevent the spread of the coronavirus.

CN

TW

EN

CN

TW

EN