Ever wondered what the effect would be of tilting you LED spot light design over a certain angle with respect to thermal behavior?

In this whitepaper MechaTronix describe the effect of tilting spot light designs over an angle of 50 degrees and 90 degrees, and compare the thermal results from LED coolers made by extrusion and pin fin technology.

|

|

MechaTronix pin fin LED. (LEDinside/MechaTronix) |

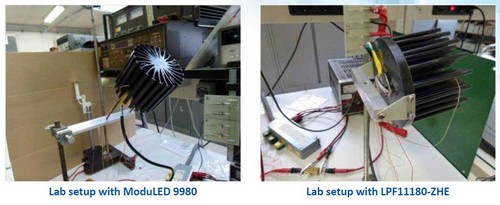

For the experiment we compare the ModuLED 9980 with the LPF11180-ZHE. The ModuLED 9980 is a passive LED cooler from extruded aluminum with a diameter of 99millimeter (mm) and a height of 80 mm, with a thermal resistance of 1.02°C/W under vertical position. The LPF11180-ZHE is a passive LED cooler with pin fin structure with a diameter of 111mm and a height of 80mm, and thermal resistance 1.07°C/W in vertical position. Both LED coolers have similar cooling performance under classic vertical position.

In this experiment we mount the same LED module from Tridonic, the Talexx Stark spotlight module STARK-SLE-G3-19-3000-830-CLA on both LED coolers with thermal grease as interface.

This Zhaga book 3 LED engine generates 30 watt of power.

|

|

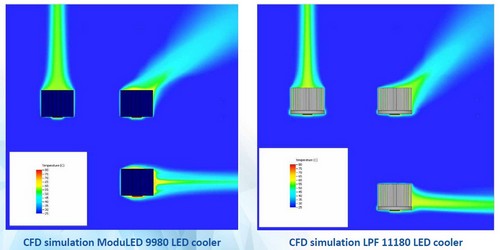

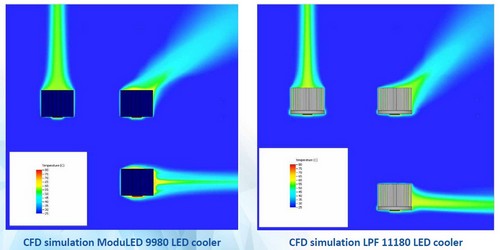

CFD Simluation for Module LED 9980 and LPF 11180 LED coolers. (LEDinside/ MechaTronix) |

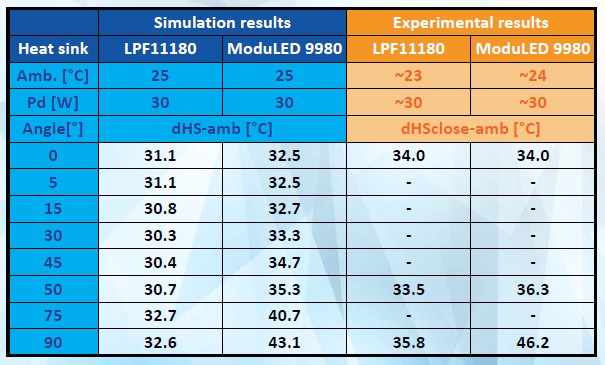

In CFD thermal simulation we change the gravity orientation to get initial results. The gravity simulated angles are 0, 50, and 90 degrees. Under vertical position both coolers give a similar result, but the heat is more concentrated in the middle from the pin fin LED cooler compared with the extruded LED cooler. This effect is seen because of the massive aluminum in the center of the extrusion and spread out heat over the fins, while the pin fin LED cooler has a more open structure in the center of the design. But cooling wise this gives exactly the same result, both coolers show a temperature on the Tc point of the Tridonic LED module of 57 degrees Celsius.

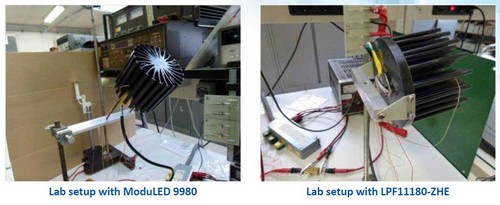

Once tilting the modules over an angle of more than 50 degrees, the pin fin LED coolers keeps on functioning while the extruded LED cooler loses more than 20% of the original cooling capacity. To verify the results of the CFD thermal simulation we made an experimental setup where the LED cooler with the LED module can be tilted from pure vertical position all the way up to a horizontal 90 degrees position. The temperature was measured by 2 calibrated thermocouples on the Tc point of the LED and in the center upper part of the LED heat sink.

|

|

ModuLED 9980 and LPF11180-ZHE lab setup. (LEDinside/ MechaTronix) |

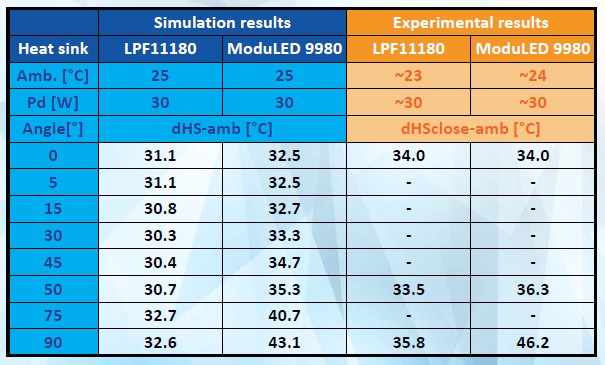

Results measured on both LED coolers were comparable when the two products were tilted up to an angle of 50 degrees. Once tilted over 50 degrees, the bottom side of the extruded LED cooler loses more cooling capacity. Since there is no forced air movement, the free air convection cooling is the main component of cooling in this way, and the radiation effect only counts for a few percent. While hot air attempt to rise vertically, open structure of the LED pin fin cooler allows air to move up without obstructions. The table below shows all the results both from CFD simulation and the experimental thermal measurements.

|

|

MechaTronix's experiment results. (LEDinside/MechaTronix) |

In conclusion, you can see that pin fin LED coolers perform better under a tilted position of more than 50 degrees than an extruded LED cooler. Even under a 90 degree orientation the cooling capacity stays almost the same. This makes pin fin LED coolers ideal for spot lighting with tilting possibilities and track lighting designs.

We would like to thank our partner Optimal Thermal Solutions for the test results of this experiment.

CN

TW

EN

CN

TW

EN