Development and installation of systems for monitoring a driver, occupants, and vehicle interior have been progressing to enhance automobile safety. Since these systems require enhanced sensing performance, advances are also required in the light sources used for the sensors. Stanley Electric has moved quickly to address these demands by working to introduce automotive infrared VCSELs to the market and to expand its lineup of infrared LEDs.

Advances in light sources demanded by new automotive applications

The automotive industry is forging ahead with the development of a variety of automotive applications to ensure road safety and enhance driver’s in-vehicle experiences. Advanced driver-assistance systems (ADAS) are an example of these. ADAS and AD (autonomous driving) utilize multiple sensors, such as cameras, radar, LiDAR, and ultrasonic, to monitor the situation in the area around the vehicle for pedestrians and other elements of the driving environment and alert the driver or exert control over driving.

For ADAS, there has been an acceleration in the development of technology for sensing both exterior and interior, to meet with technology that requires high performance in the ADAS and AD. This includes DMS (Driver Monitoring Systems), which use a camera to monitor the face of the driver to detect when they are dozing or looking away from the road. Adoption of DMS is being led by automotive manufacturers in China and Europe. Additionally, the EU has mandated that all new cars sold in Europe must be equipped with DMS by 2026.

It is important that the sensing of subjects by DMS and OMS is optimal in both scope and precision. This requires improvements in the performance of the software (algorithms) and camera modules that process the images. The infrared light source that is used with the image sensor in the camera module is one of the devices for which there are new requirements.

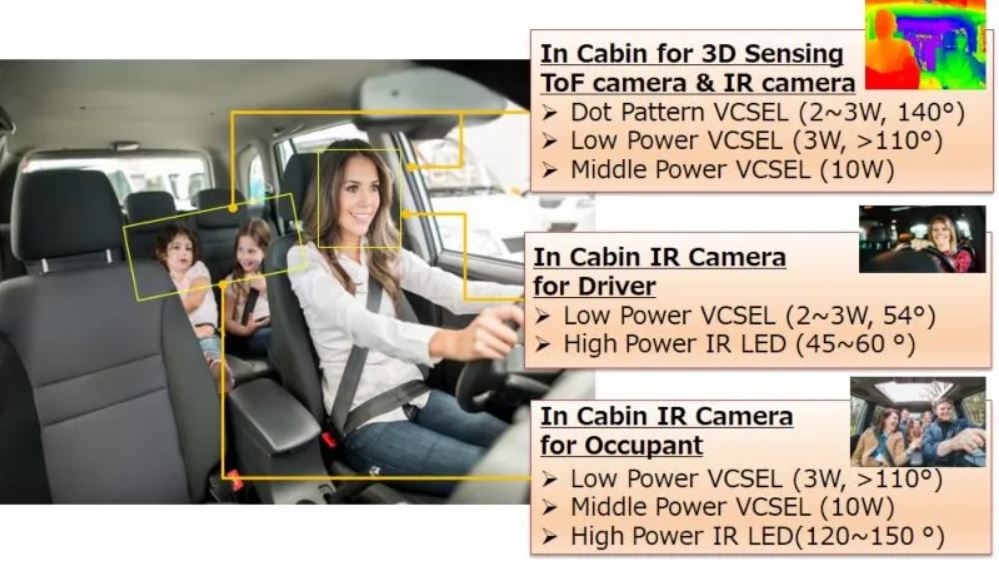

Infrared LEDs are mainly used as light sources for image sensors, but the need for higher performance in DMS/OMS has resulted in requirements that are difficult to meet with existing infrared LEDs. In many cases, different models of vehicle have the DMS camera mounted in different locations, such as the steering wheel, pillar, or center console. This requires an infrared light source in which the light distribution can be controlled to optimize the camera’s Field of View (FoV). Because OMS monitor the whole of the vehicle interior, there is a pressing need for infrared light sources that have higher power output and that can detect people and objects in higher resolution when used in sensors.

In the case of DMS and OMS, infrared rays from the light source are used to illuminate the driver and passengers, and a CMOS camera is used to record the images. The recorded images are analyzed for movement in the driver’s gaze and eyelids, and judgments are made on the level of the driver’s attentiveness and fatigue, based on which the driver may be alerted. This system can be designed to detect items forgotten or left behind in the rear seats and send alerts to the driver’s smartphone. 3D Time of Flight (ToF) technology, which consists of a camera and an infrared light source such as VCSEL, enables high-resolution image analysis and realizes higher performance of these DMS/OMS application functions.

Stanley Electric has expanded its lineup of infrared light sources to meet these needs. The company has been developing and commercializing infrared LEDs since the 1970s, and already has a certain presence in the market. In recent years, Stanley Electric has been focusing on the development of a VCSEL (Vertical Cavity Surface Emitting Laser) for automotive applications. By leveraging the individual characteristics of both infrared VCSELs and infrared LEDs, the company has expanded its lineup of products with specifications that make them easy to use as light sources for DMS and OMS sensors.

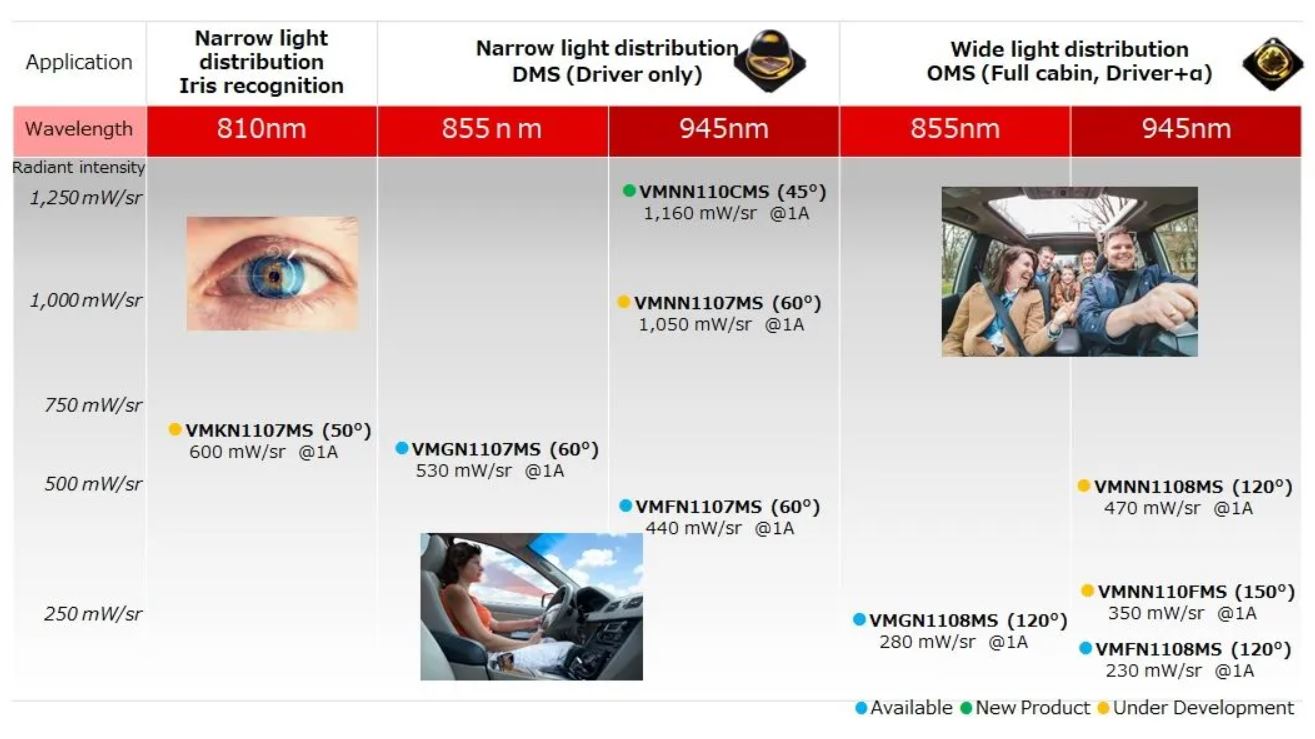

Examples of infrared VCSELs/LEDs suitable for use as light sources for DMS/OMS sensors. Source: Stanley Electric

Infrared VCSELs that enable 3D-sensing systems

Infrared VCSELs are a kind of semiconductor laser that emit laser light vertically from the substrate. They have high directivity, less impact of temperature conditions or the way they are driven (use of high current to activate), and then have stable performance. Another characteristic is that because their emission spectrum is much narrower than that of infrared LEDs, the passband of a band-pass filter can be made tighter so that the effects of sunlight (disturbance light) are suppressed.

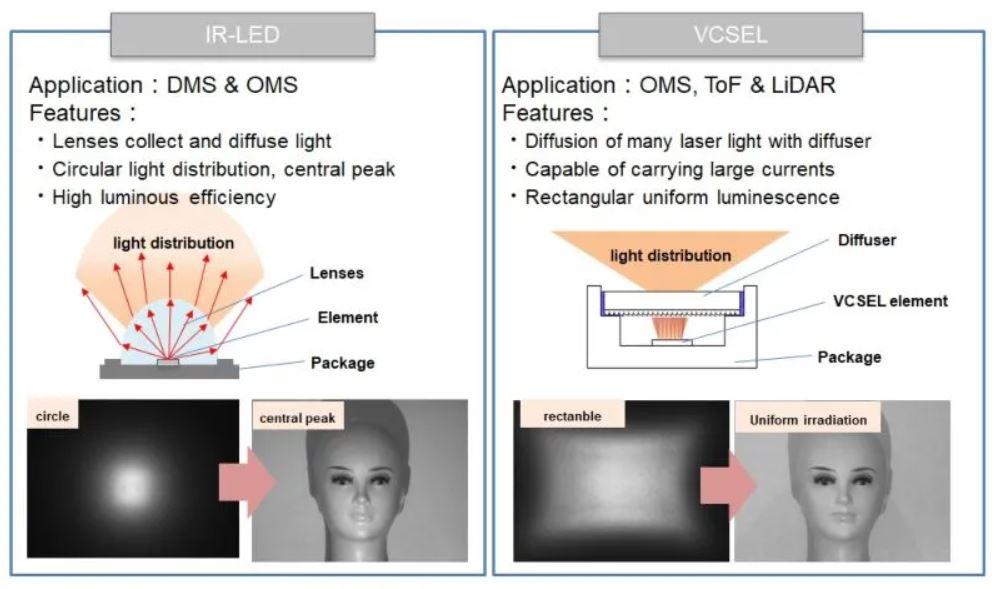

The difference in particular from LEDs, is VCSEL’s irradiation pattern and responsivity.

The irradiation pattern of LEDs is strongest in the center and that spreads out in a circle. Infrared VCSELs use a diffuser to scatter the laser light emitted from the element to achieve wide-angle, uniform illumination in the view, while at the same time preventing focused laser to ensure safety for the human eye. In contrast to LEDs that are combined with lenses to gather or disperse light and provide wide illumination of spaces, infrared VCSELs use diffusers to disperse light and uniformly illuminate the surface of rectangular shapes. High-resolution sensing required for DMS/OMS, is achieved by this infrared VCSEL characteristic of uniformly illuminating rectangular shapes to illuminate the FoV of the camera evenly.

Differences in the structure and light distribution of infrared LED and infrared VCSEL devices. Source: Stanley Electric

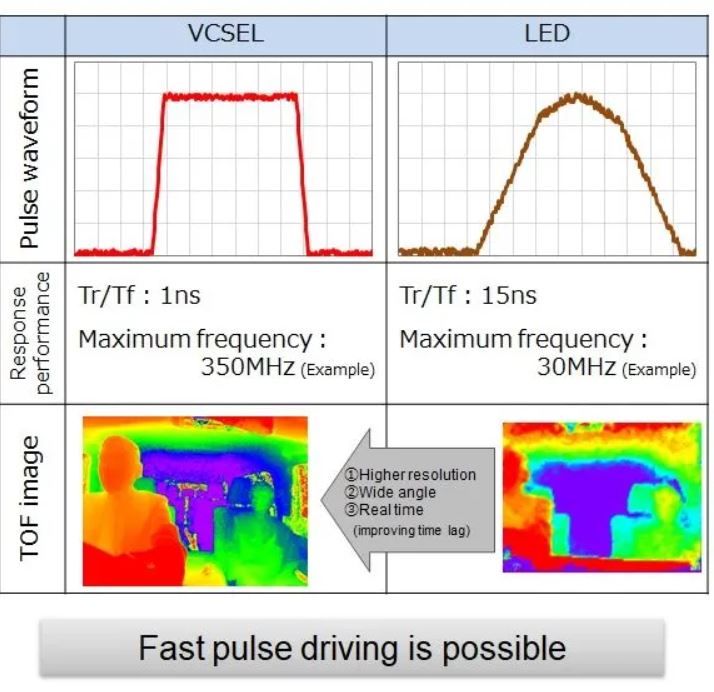

The response speed of an infrared VCSEL is significantly higher than that of an LED. Pulse rise and fall times for LEDs are 10-15nsec, whereas at 1nsec for infrared VCSELs. Thus, VCSELs respond 10 times faster than LEDs by simple calculation. When used as the light source for a ToF sensor, a VCSEL can achieve higher ToF image resolution, wider angles, and closer to real-time performance (lower latency) than an LED light source. It is because of these characteristics that infrared VCSELs are the best choices for applications such as 3D sensing for OMS, or recognizing in 3D extraordinarily complex movements and gestures of the driver and using them as feedback to control the vehicle.

Comparison of response speed in infrared VCSELs and LEDs. Using an infrared VCSEL with high response speed as the light source for a ToF sensor will result in clearer ToF images. Source: Stanley Electric

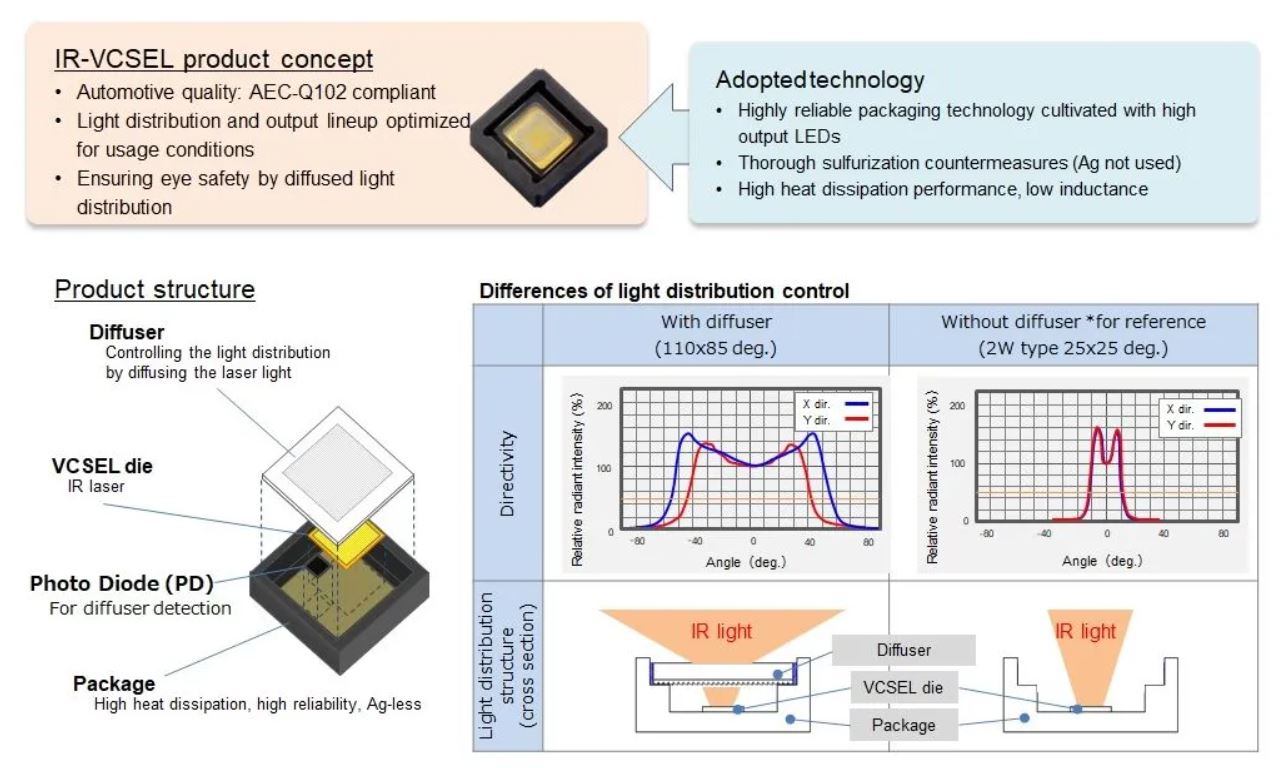

Stanley Electric has begun mass production of the UDN1ZE65 with optical output power of 2.1W, and the UEN1ZA9 with 2.8W. Both have a wavelength of 940nm. They are compliant with the AEC-Q102 automotive quality standard. In terms of eye safety, they have achieved Class I (inherently safe by design) under the IEC 60825-1 international standard and the United States’ CFR Part 1040.10 standard for laser products.

Another characteristic is that no silver is used in the package. When silver is used in the electrodes of electronic components’ packages or other applications, sulfur-containing atmospheres can cause sulfurization of the silver, generating silver sulfide that can in turn lead to failure of the element or component. For this reason, the basic approach in the industry is to avoid using silver in automotive components, and Stanley Electric has implemented thorough measures to prevent sulfurization in its infrared VCSELs.

Stanley Electric also offers a product with a PD (photodiode) mounted in the package to receive scattered light from the diffuser. Using this mechanism, the PD stops receiving reflected light if the diffuser comes off, which is then detected as a fault. Stanley Electric has plans to prepare PD-equipped packages for all upcoming development products.

Structure of infrared VCSEL device and variations in illumination caused by controlling light distribution. Source: Stanley Electric

Moreover, an infrared VCSEL with an output of 9.2W is also under development. This product significantly increases the output of two existing products in response to growing demand, in Europe and in other regions where the installation of DMS is becoming mandatory, for the ability to view the whole of the vehicle interior. Engineering samples of the 9.2W product have been shipped, and it is scheduled to be released by the end of 2023.

Extensive infrared LED lineup, from low to high power and from narrow to wide angle

Infrared VCSELs with high-speed responses are well suited to certain applications, such as ToF sensors and gesture control, but there is still considerable demand for infrared LEDs, which have already proven in the market, and which are economical than infrared VCSELs.

Stanley Electric has been involved in the automotive application business with infrared LEDs for many years. Based on the experiences, they have expanded the automotive-spec V-Series for use in DMS and OMS and are offering an increasing number of variations in terms of wavelength, output, spatial distribution, and other characteristics. All these products are compliant with the AEC-Q102 automotive quality standard.

Stanley Electric enhances the lineup of high-power infrared LEDs with high radiant intensity. Source: Stanley Electric

The company has expanded its lineup of the narrow light distribution type with spatial distribution of 60° or 45° for use with DMS that only require the driver’s face to be visible. In addition to the 945nm products on which it has focused in the past, Stanley Electric has added the 855nm VMGN1107MS. 945nm is a wavelength that is resistant to the impact of ambient light, but with the number of cameras being used in DMS/OMS on the increase, the light emitted by light sources causes mutual interference. This resulted in the development of VMGN1107MS, a product that is resistant to the effects of noise. In terms of 945nm products, the company has added VMNN110CMS, which achieves radiant intensity (at 1A) of 1160mW/sr with a spatial distribution of 45°, and an 1150mW/sr product with a spatial distribution angle of 60° is also under development.

Because this has both narrow light distribution and high power, it has the advantage of either enabling the outer lens to be made smaller or making the outer lens unnecessary. This leads directly to a smaller size for the optical unit.

OMS that must view the whole of the vehicle interior are increasingly using wide light distribution products that can emit at a wider angle. Existing products have a spatial distribution of 120°, but 150° products are under development. Stanley Electric is also moving forward with the development of new 120° products with higher radiant intensity.

Increasing infrared LEDs with different light distribution and output characteristics also leads to a decrease in optical design. As mentioned above, the requirement of light distribution and irradiation distance for the cameras’ field of view depends on the variety of positions where DMS/OMS cameras are mounted. When there are limited options for infrared LEDs, this may require additions to the optical components or system, resulting in less flexibility of design and cost increases.

Infrared LEDs are also under development with a focus on future automotive applications, such as payment by face recognition or unlocking of security features through biometric authentication. For these applications, specifications are with the wavelength of 810nm, which is suited to iris recognition, with a spatial distribution of 50° and a radiant intensity of 600mW/sr.

Increasing adoption in China

By beginning mass-production of infrared VCSELs and expanding the lineup of infrared LEDs, Stanley Electric now has a product range that can respond to the needs of DMS/OMS sensing.

The number of infrared VCSEL and infrared LED design wins has already reached 26 auto manufacturers and 30 different types of platforms. More than 20 other projects are currently being proposed or evaluated. Progress is particularly noticeable in China. In contrast to Europe, where the market is forecast to expand as a result of the mandating of DMS for vehicles, China has a strong tendency to add new functions regardless of legislation. For this reason, many auto manufacturers have taken a proactive approach to adopting DMS and OMS, and Stanley Electric’s infrared VCSELs are already used in the vehicles of multiple Chinese and European automotive manufacturers.

Driven by Chinese and European market, the number of vehicles equipped with DMS/OMS will certainly grow. Accordingly, this will lead to more differentiated specifications for sensor light sources. In that event, Stanley Electric, which has both VCSELs and LEDs as infrared light sources and is continuing to expand its lineup of both product ranges, should be a reassuring ally for designers of DMS/OMS.

TrendForce 2023 Infrared Sensing Application Market and Branding Strategies

Release: 01 January 2023

Format: PDF

Language: Traditional Chinese / English

Page: 164

|

If you would like to know more details , please contact:

|

CN

TW

EN

CN

TW

EN