|

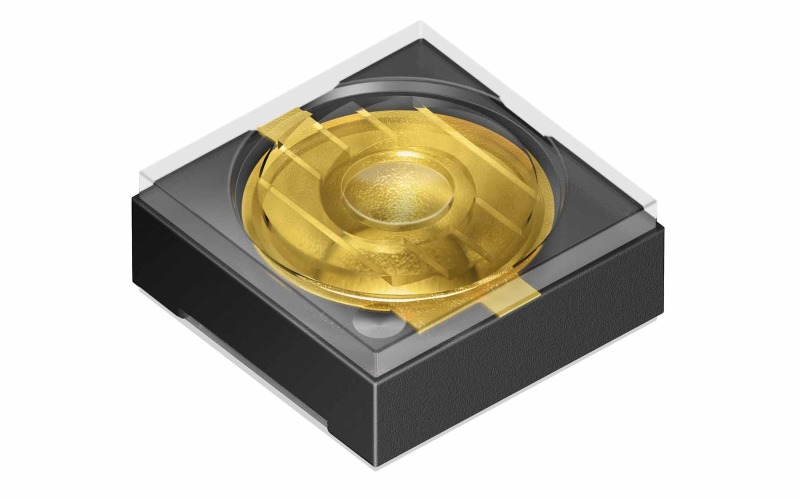

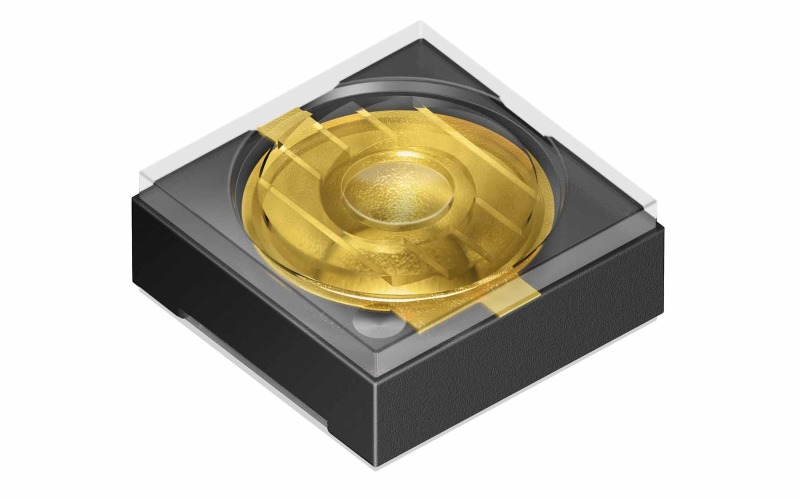

The new Oslux SFH 4786S infrared LED (IRED) from Osram is around one-third thinner than its predecessor. (Osram Opto Semiconductors/LEDinside)

|

The new Oslux SFH 4786S infrared LED (IRED) from Osram Opto Semiconductors enables iris recognition systems to be made less complex and with lower profiles. At 1.6 millimeters (mm) high, this new IRED is around one-third thinner than its predecessor. Its direction of emission is slightly angled so there is no need for the usual mechanical aids to ensure correct geometrical alignment.

Recognizing different iris patterns from one person to the next is one of the most reliable biometric identification methods. This technology has recently been adopted in smartphones and tablets to protect them against unauthorized access. In 2014, Osram Opto Semiconductors launched the Oslux SFH 4780S, the first IRED that enabled compact and reliable iris scanners to be integrated into mobile devices. The 2.4 mm high SFH 4780S is optimized primarily for maximum light extraction whereas the new Oslux SFH 4786S features the same high light extraction performance but its height has been reduced to only 1.6 mm to meet the demand for extremely low-profile emitters in designs where very little height is available.

A completely new feature is the 8° tilt in the emission direction of the SFH 4786S. The slightly sideways emission characteristic is beneficial for the field of view of the camera mounted a slight distance away. The performance of the overall system is significantly better than one with an emitter slightly emitting vertically upwards. “Up to now, mechanical means have been used in iris scanners to tilt the IRED slightly,” said Chris Goeltner, Product Marketing Manager, IR, at Osram Opto Semiconductors. “However, this additional expense is no longer needed with the SFH 4786S. This greatly reduces the level of complexity in designing iris scanners.” Designers also benefit from the somewhat broader emission angle of +13°, which allows a larger area to be illuminated at the customary working distance for iris scanners in mobile devices. The radiant intensity of the SFH 4786S is typically 1,750 milliwatts per steradian (mW/sr) at a current of 1 amp (A).

Like the SFH 4780S, the SFH 4786S emits light with a wavelength of 810 nanometers (nm). In this spectral range, it is possible to achieve high-contrast images for all iris colors. The chips are of Nanostack design which provides two emission centers per emitter, resulting in maximum optical output. Both IREDs are based on the highly efficient Oslux package, which focuses the light very tightly with its reflector and an appropriate internal lens. It is capable of providing very high radiant intensities and also of being extremely easy to process thanks to its flat surface. Also worth noting is the low thermal resistance of the package of 25 kelvin per watt (K/W). Compared to the SFH 4780S, the only difference designers have to take into consideration is the smaller component height of the SFH 4786S; the footprint remains the same.

The SFH 4786S is now available upon customers’ requests. Volume production is planned for start-up at the end of January 2016.

CN

TW

EN

CN

TW

EN