The leader in thin, engineered lighting solutions today announced the availability of its first-ever, innovative Cut-2-Size™ Backlighting Kit. Created for design engineers who need quick prototype backlighting for membrane switches, keypads, overlays, LCDs or other graphics displays, the Cut-2-Size Backlighting Kit is available from Lumitex. It can also be used for fast-turn, small volume production.

|

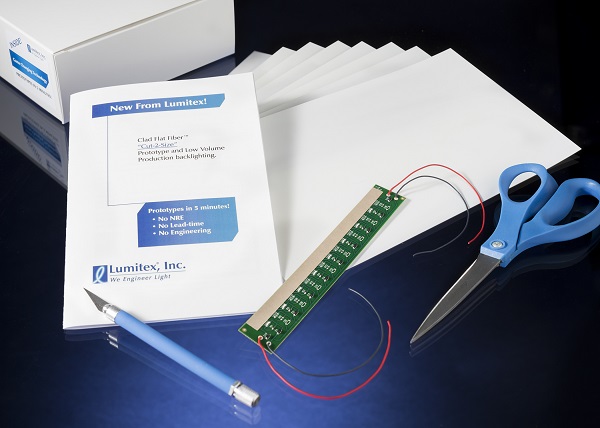

Lumitex launches new backlighitng kit that allows users to cut and trim the panels to an desired size. (All Photos Courtesy of Lumitex)

|

Requiring no tooling or non-recurring engineering (NRE), the Cut-2-Size Kits include either 0.45mm or 0.3mm thin, 6” x 11”, Clad Flat Fiber™ (CFF) flexible optical sheets; and printed circuit boards with eight, white side-fire LEDs that can be powered by a standard 9VDC supply. The polycarbonate panels can be easily cut into any shape or size using standard cutting tools such as scissors or a knife. The LED board can also be cut, creating two separate boards. An adhesive strip on the circuit board acts to stabilize the transition edge and allow better coupling of the light guide panel.

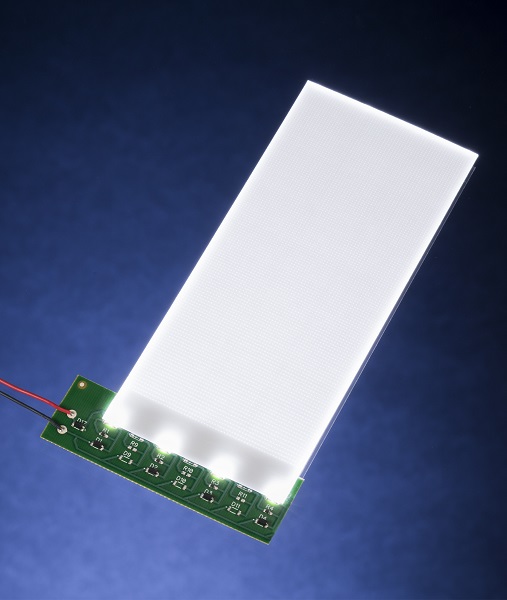

“These Cut-2-Size panels with integrated back reflectors use Lumitex’s patented light extraction method, distributing photons across the surface of the panel to achieve a uniform, integrated light without heat, surface electricity or EMI.” said Mark Darby, Vice President of Electronics Sales.

|

|

The panels with integrated back reflectors use Lumitex’s patented light extraction method. |

“Advanced lighting technology in easy-to-use, Cut-2-Size panels makes it simpler and faster for designers to light their prototypes, giving their customers a better idea of what the final product will look like and how it might function.” Darby said.

“The rapid prototyping and small volume production capabilities of Cut-2-Size Backlighting will speed customer decisions, bringing new products with better lighting to market sooner in automotive, medical, electronics, and instrumentation markets,” Darby noted. “Once prototyped, projects can be optimized with a custom optical solution. Lumitex works closely with engineering teams to develop the best integrated lighting solution for higher volume or more complex applications.”

Clad Flat Fiber technology offers high brightness and requires less power than LED arrays and most LED light guides. It also provides consistent performance in hazardous environments, withstanding a wide temperature range, high humidity, shock and vibration.

CN

TW

EN

CN

TW

EN