Heraeus Precious Metals is pleased to announce the continuing performance growth and reliability of Celcion™.

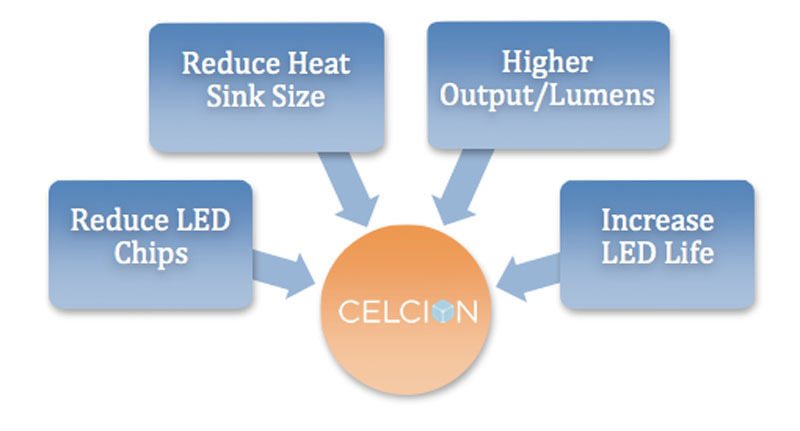

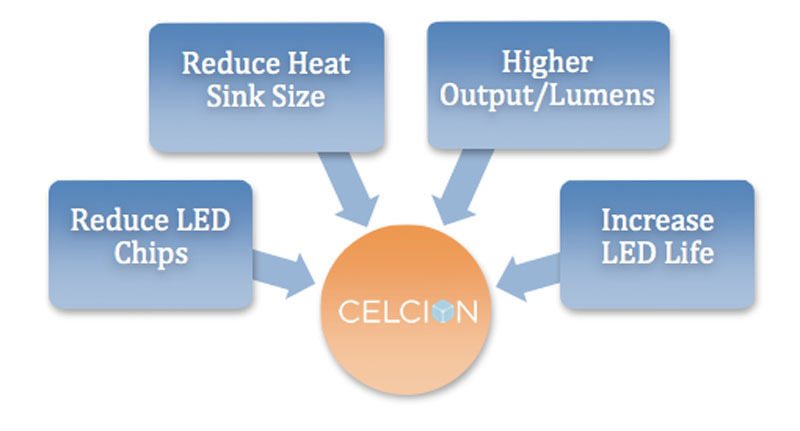

Celcion™ is a thick film material system designed to produce electronic circuits for LED lighting on aluminum substrates. It is a highly efficient alternative to traditional metal core printed circuit boards (MCPCBs) and offers several significant advantages:

• Typically 10 degrees C or more cooler

• Long Term reliability

• Higher Output

• Longer LED life

• Lower material consumption

• Simplified bill of materials

|

Heraeus Celcion™ is able to take the same fit as MCPCBs however delivers increased thermal connectivity and high dielectric breakdown strength. It incorporates a selective additive deposition process using material only where it's needed, resulting in less material consumption and a simplified bill of materials. Through use of a limited amount of material and the removal of interface materials that increase thermal resistance, Celcion™ provides a more direct connection to the aluminum heat sink, reducing the need for heat spreading layers and reducing the thermal footprint. Celcion™ circuits typically run 10 degrees C or more cooler than MCPCBs. Because Celcion™ circuits run cooler, one can increase the power output thereby reducing the number of LEDs needed by up to 20%. This decreases production costs without sacrificing performance. Heraeus Celcion™ is ideal for high-power applications, including high-power LED substrates (>1W input) found in general illumination, signs, signals and displays with noted increased performance benefits in other applications such as power electronics and heaters.

With the successful completion of environmental stress testing, the Heraeus Celcion™ system has proven long-term reliability. This is a necessary requirement for satisfying the high demands of customers. Celcion™ passed tests under some of the most severe conditions of many customers' applications demonstrating high levels of dependability.