|

|

Illumitex Chief Technology Officer Dung Duong. (All Photos Courtesy of Illumitex) |

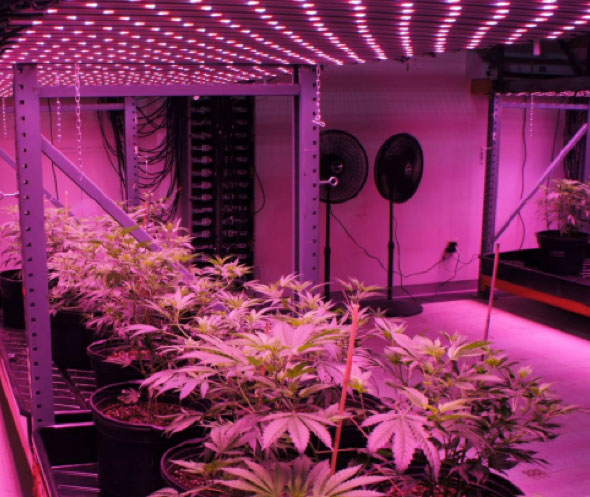

Since inception, Illumitex has invested more than US $45 million into the development and commercialization of our innovative LED technology. An expert in the field of optics, company founder and Chief Technology Officer Dung Duong based the design of Illumitex LED optics on basic physics principles, which ensure that the vast majority of the photons being emitted from the LEDs are captured and delivered directly to the cannabis canopy. As a result, the highest level of efficiency and light intensity is achieved in a proprietary and patented LED package. A vertically integrated company, Illumitex manufactures its LED packages in Penang, Malaysia (including robotic die placement, gold wire bonding, phosphor application and optic assembly) and assembles fixtures in Austin, TX.

Horticulture science expertise

Illumitex is not just another company that decided to jump on the bandwagon of the emerging legal cannabis industry. Our company was founded on the development of scientifically proven lighting solutions specifically for horticulture and we have been working with growers in Colorado since 2011. Plant scientists on staff not only ensure that Illumitex products will exceed the expectations of our customers, but also provide invaluable support and guidance. We are not interested in simply selling lighting products — our value goes much further by providing knowledge and experience in all aspects of cannabis cultivation.

|

|

Paul Gray, Illumitex Senior Plant Scientist and VP of Horticulture Lighting. |

Paul Gray, Illumitex Senior Plant Scientist and VP of Horticulture Lighting, holds both Bachelors’ and Masters’ degrees in botany and microbiology from Stephen F. Austin State University, where his graduate research emphasized the use of controlled environment techniques that allowed him to statistically quantify a plant’s ability to defend against plant pathogens. This work was then used to develop plant breeding programs now in use by the U.S. Department of Agriculture and the Natural Resource Conservation Service. Paul’s botanical and controlled environment agriculture expertise merges with his lighting engineering knowledge to assist in developing the right lighting solutions for Illumitex clients.

Product engineering & construction

Illumitex’s talented and knowledgeable team of engineers thrives on producing horticulture fixtures that combine aesthetic style with functionality, outstanding performance and long-lasting durability. Our slim fixture designs and IP66 ingress protection ratings against intrusion of water and dust make it possible for experienced growers to stack grow levels vertically, thus maximizing production. Unlike some fixture manufacturers, each fixture produced by Illumitex is ETL and cETL listed per UL safety standards. Additionally, every single fixture shipped from Illumitex is powered up for a “burn-in” period prior to packing and shipping to ensure the highest level of quality.

Services

As an additional benefit to our customers and potential customers, Illumitex will create detailed DIALux lighting reports for your operation’s particular grow space geometry indicating recommended fixture placement as well as expected PPFD and uniformity values. Our goal is simply to provide the best lighting solution possible for your specific horticulture needs and budget.

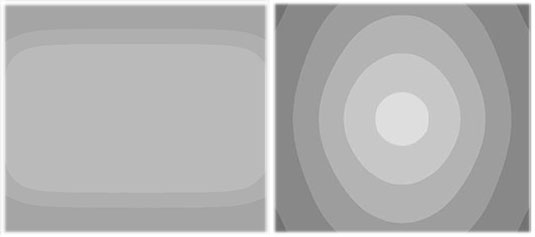

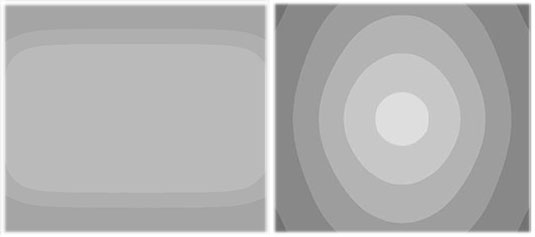

Light and spectral uniformity

The result of our optical innovation is perfect uniformity of light intensity and color delivered to the entire cannabis plant canopy. This means there is no plant damaging “hot spot” over the center of your grow that trails off to a much lower light intensity at the perimeter as is common with other technologies and manufacturers. Our even uniformity ensures consistent growth and yield for all of the plants within your grow space, not just those near the center.

|

|

Left, even uniformity of light intensity from Illumitex over 4×4 grow area. Right, uneven light levels and hot spot from HID and induction lighting over 4×4 grow. |

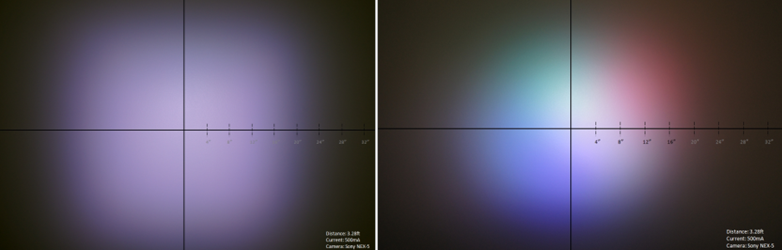

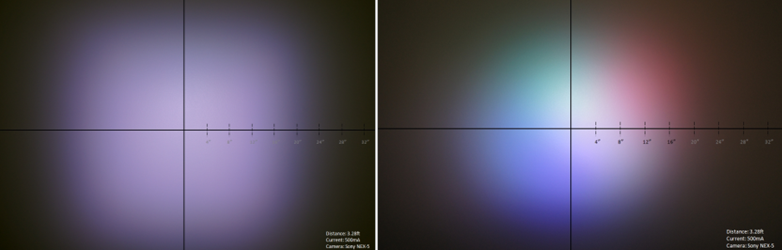

Since Illumitex’s technology allows the combination of 16 LED chips of different wavelengths within a single ½”-square package, perfect color blending is achieved directly beneath the emitting surface of the fixture. Other LED fixture manufacturers are forced to alternate LEDs with different wavelengths along the fixture emitting surface – sometimes as much as three inches apart. This design restriction results in uneven color uniformity on the plant canopy and therefore, uneven plant growth and yields.

|

|

Left, perfect color blending from Illumitex Surexi™ LED technology. Right, uneven color blending from other LED fixture manufacturers. |

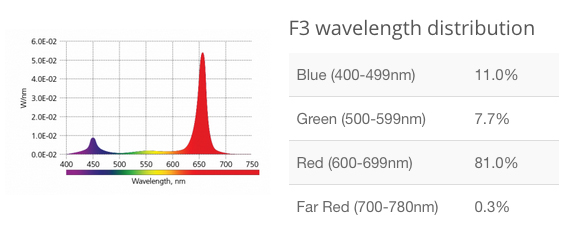

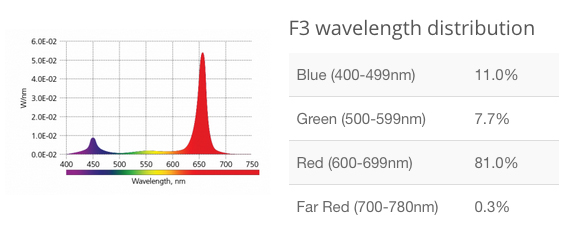

Single spectrum for veg and bloom

The workhorse and most popular spectrum from Illumitex, F3, produces the best vegetative and flowering results among all of the Surexi™ spectra options. Each Illumitex Surexi™ F3 LED package provides an ideal combination of wavelengths from the blue and red PAR spectral range scientifically designed to facilitate superior vegetative through flowering growth. The F3 spectrum also includes a small amount of green which is especially beneficial for the quality assessment of plants. With Illumitex’s F3 spectrum, there is no need to change fixtures and lamps or relocate delicate plants from one room to another during the growth cycle. Simply reduce the daily light integral (DLI) to facilitate the flowering response. The F3 spectrum is recommended for use in controlled environment agriculture operations of any size.

|

|

Low energy consumption and heat generation. |

Requiring less than half the energy of incumbent technologies such as high pressure sodium (HPS) or metal halide (MH), LED fixtures from Illumitex can be a significant factor in reducing the overhead of a large grow operation. In addition to the fixture energy savings, Illumitex products generate less than half the heat as these older technologies meaning less energy cost required to remove the heat generated by means of HVAC, fans or chillers. In a new operation, a substantial savings in capital expense can be realized due the reduction in HVAC equipment requirements. Extremely low forward heat generation also means there is no potential for harming plants as a result of having the fixture too close to the canopy.

Long life

Rated for 60,000 hours of operation until L70 (the point at which the intensity of light from the LED is 70% of the initial level), you can expect your Illumitex horticulture products to deliver high quality lighting to your plants for nearly 15 years and very beneficial light levels for many years afterwards with no need to ever replace or dispose of old lamps.

Results

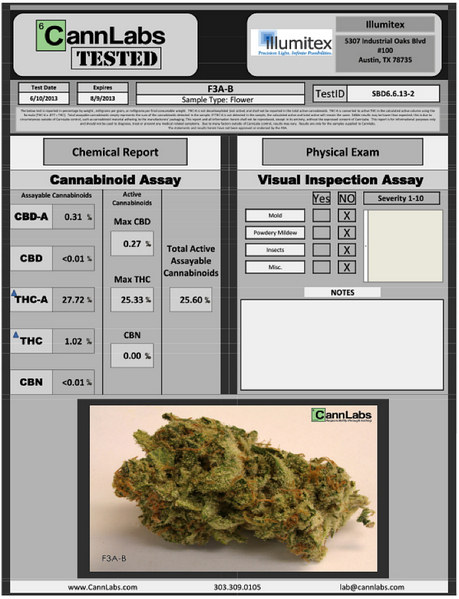

Independent lab tests have revealed a 19 percent increase in CBD and a 24 percent increase in THC in a side-by-side comparison between Illumitex fixtures with the F3 spectrum and high pressure sodium fixtures (see test data below).