CSP LEDs developed by Taiwanese LED manufacturer Genesis Photonics Inc. (GPI) are being shipped to Japan, Europe and U.S. markets is gradually taking off. In a recent interview with LEDinside, the company’s CEO Mark Chen analyzed the company’s wafer level Chip Scale Package (CSP) LEDs that were an extension of its flip chip technology, and the advantages these products have in future niche market applications.

The advantages of CSP LED products

GPI started in-house developing CSP LEDs many years ago, and has applied for patents in Taiwan and oversea markets, said Chen. The company’s patent portfolio for flip chip and CSP technology covers more than 100 patents. The company has shipped its products to clients, and formed partnerships with related clients to fully optimize CSP package products advantages and technology adjustments. Chen noted though, CSP products are not a replacement of current LED package supply chain, but offer the industry various development options.

|

|

Genesis Photonics Inc. (GPI) CEO Mark Chen. (All photos courtesy of LEDinside) |

There are many different types of traditional LED packages the scope ranges from wire bonding, substrates, and electric circuit board materials used in high power LEDs to Plastic Leaded Chip Carrier (PLCC) and COB package products. The industry should develop different LED package products to meet LED backlight and LED lighting application features. The developments of CSP LED packages on the other hand, is a type of chip technology that has upgraded and changed LED package structure. CSP LEDs are capable of cutting traditional LED package costs, and issues related to light focus angle, reliability, brightness, and structural strength.

Some CSP LED products sold on the market by manufacturers are just flip chip LEDs coated with phosphor powder and LED adhesives, but are not good quality CSP LEDs, said Chen. These fake CSP LEDs have a weak chip structure that cannot protect the LED chip, and once the product encounters reliability issues, there will be all sorts of feedback from the market. Manufacturers are often forced to improve the product’s design. GPI uses a wafer level packaged CSP structure to integrate the leadframe inside the chip, and offer good optic designs, which makes the chip much smaller, while offering the same reliability as Plastic Leaded Chip Carrier (PLCC) packaged products. Moreover, CSP LEDs offer various advantages of eliminating the need for wire bonding, while shrinking the epiwafer size. The strengthened leadframe structure and chip processing completed at the epiwafer stage, the product is much thinner than most products on the market.

Most importantly, GPI has invested vast resources and amount of time to improve yield rates, chip processing, planning and R&D. Hence, in terms of the epiwafer packaging process the company has achieved excellent yield rates and delivered very good performance in 4-inch MOCVDs. Clients have responded well to epiwafers supplied by GPI.

|

|

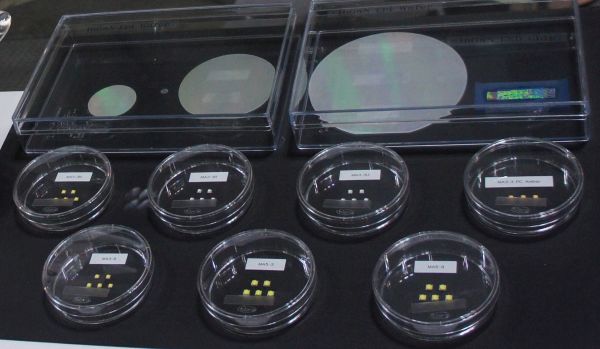

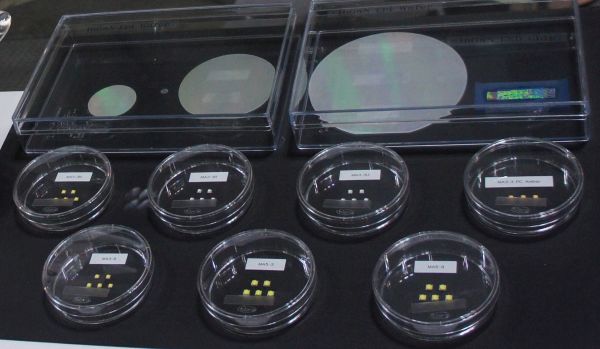

GPI's wafer level CSP LED products showcased in the first two rows. Epiwafer products can be seen in the back row. |

Design-in solutions optimizes lumens per area

The greatest advantage in CSP LEDs is GPI customizes solutions for clients, since optic designs are involved, the CSP LED product size can be minimalized, due to the reduced leadframe to accommodate the optic design. Additionally, the lumens per area is significantly increased, which improves the product design’s flexibility. From the end-user aspect, the thinner the product, the more flexible the optic design becomes, and the product can become more reliable. Hence, CSP LEDs can offer design-in solutions.

What is GPI’s design-in solution?

U.S.LED manufacturer’s high power LED chip products is well-known on the market for its torch light applications. By adding a good optic lens, and a good flash LED structure product shipment to manufacturers and clients can run smoothly. Yet, how can manufacturers offer a solution for clients that want a smaller LED component with the same power output as a larger flash LED component, but at the same time want the smaller LED to have a longer and more efficient illumination? GPI has a solution that can offer smaller LED chips on the market, for example the solution can offer chips a quarter of the size of conventional white LED chips. These LEDs have better optic designs, light focus, and luminous efficiency per surface unit.

|

|

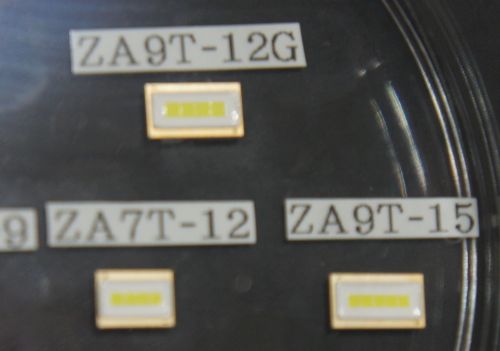

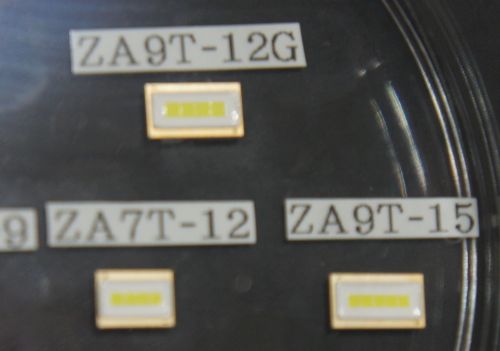

GPI's CSP LED products ZA7T-12, ZA9T-15, and ZA9T-12G. |

In terms of LED backlight applications, GPI is supplying ultra-thin 0.3mm CSP LEDs, about half the thickness of average CSP LEDs 0.6 mm thickness. These ultra-thin CSP LED packages can be directly used in thinner direct-type LCD TVs, and can improve the thickness and efficiency of TV sets. Some big TV brands have applied thin Corning glass light guide plates in side-view type LCD TVs. GPI also offers super small 1810 CSP LEDs that allows the LCD TVs to be even thinner. The LEDs have a luminous flux of 72 when driven at currents of 200 mA, voltage of 3V, and temperature of 25℃.

CSP LEDs cannot directly replace the LED package supply chain, but is part of the industry’s diverging technology trend

For GPI, its CSP LED product portfolio’s market position is not aimed at replacing the current LED package supply chain, but are the byproduct of market changes in the industry including the trend of diverging chip technologies. Under the current industry development and economic scale, large enterprises have only become bigger, while small manufacturers are still searching for their own sales markets to manage operations.

CSP LED market applications in traditional backlight and lighting applications still faces pricing competition from existing products, but in niche lighting applications and automotive lighting applications, clients have better design flexibility. Special commercial lighting applications, high bay lights, spotlights, torch lights, and smartphone flash lights and other spotlight products optic designs could adapt CSP LED products to achieve focused light. Hence, CSP LED product lumen per area (measured in lm/mm) can be optimized.

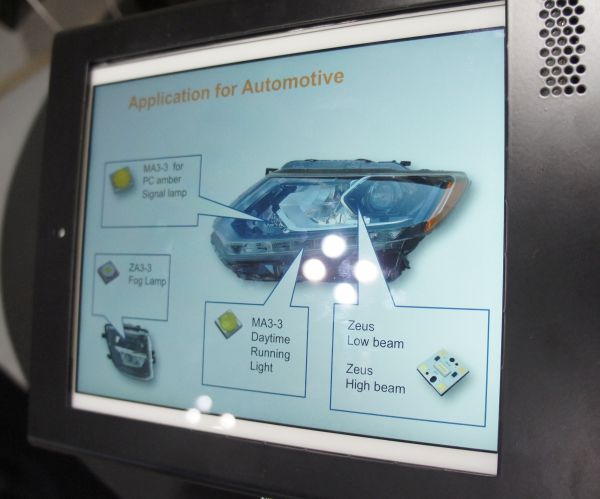

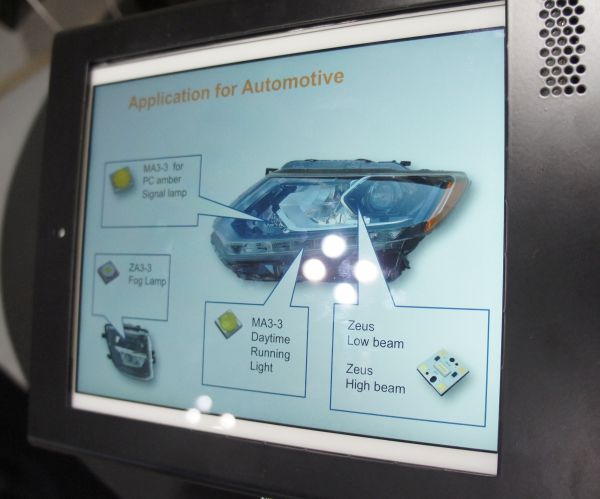

GPI’s LED products have received TS 16949 certification in the automotive lighting market, and the company has entered major Taiwanese and international manufacturers aftermarket supply chain. The company has used its experience in automotive LEDs and product structure advantages to collaborate with automotive manufacturers in developing automotive lights. This has stabilized the company orders and aided future developments.

|

|

GPI's automotive LED product portfolio. |

GPI has offered various solutions to clients, and once the client is satisfied GPI can offer different LED chip, package and module solutions. The company can also cooperate with different LED packaging manufacturers, in short GPI’s management strategy is flexible, and is not aimed at replacing LED packaging manufacturers. The company is strengthening its partnership with LED packagers and end market manufacturers, each company specializing in its own field to find the most suitable niche market for CSP LEDs to achieve the greatest effect.

|

|

A LED headlight. |

In the future GPI’s CSP LED package shipment share will only increase, and its traditional LED revenue share will decline steadily. Although, the company will not observe significant revenue growth in the short term, by collaborating with different clients in the long term, it will be able to introduce new design concepts and solutions to achieve suitable growth. The company’s long term management strategy will shift towards products with high gross margins, and is a direction worth exploring and discussing among Taiwanese LED manufacturers.

(Author: Ivan Lin, Head of Content Development, TrendForcehttp:// Translator: Judy Lin, Chief Editor, LEDinside)