Soraa’s Chief Electronics Architect Laszlo Takacs explains two important stages in designing flicker-free luminaires.

In a previous blog entry, Soraa’s Chief Scientist Aurelian David pointed out the importance of having low flicker was made clear. But just how low is low enough? And from an engineering perspective, how much effort is required to get there?

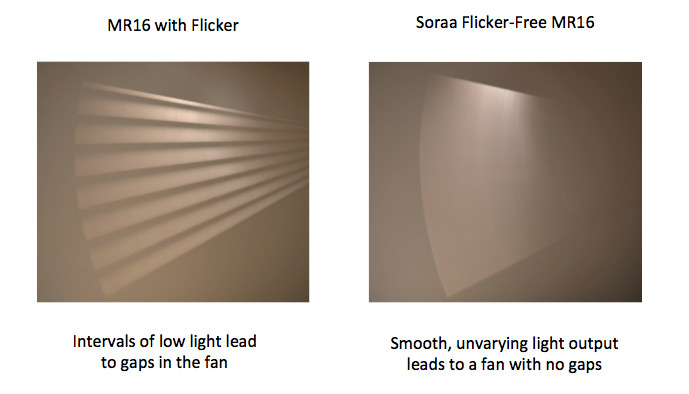

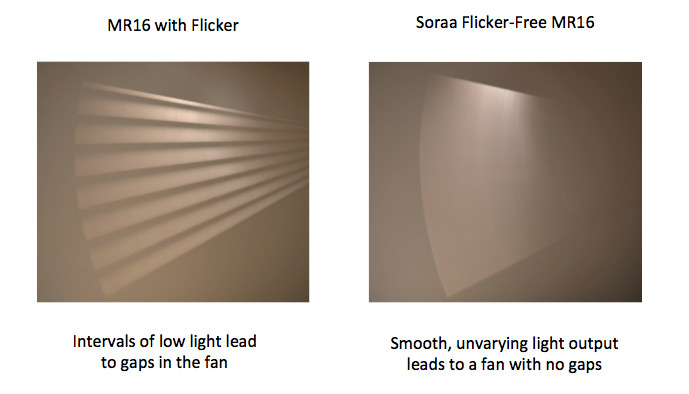

Ultimately you want the flicker to be so low that it can’t be seen, that there is no detectible biological (unseen) effect and there are no visible artifacts with modern electronic cameras. In short, the flicker should be completely undetectable outside the laboratory. This definition of “low enough” is admittedly the extreme. It also happens to be Soraa’s starting point for the design of its new flicker-free MR16.

|

|

Soraa demonstrates the difference between MR16 with flicker and the company's flicker-free MR16 which delivers a smooth lighting output. (Photo courtesy of Soraa) |

With extreme performance you get extreme engineering challenges. So what do you have to do to completely eliminate flicker in a tiny lamp like the MR16? You have to begin with the physics of flicker and translate the physics solution into the outline of an electronic circuit that can do the job. You then have to fill in the details of that circuit in such a way that it physically fits into the lamp, doesn’t get too hot, and doesn’t break the bank. And along the way you will discover more than a few surprises. Here’s how it happened, step by step.

The physics required two electronic stages. Eliminating flicker completely meant that two separate energy converters (called stages) needed to be used instead of the usual single-stage converter. The first stage would accept power riddled with all the possible fluctuations and flicker-producing variability of an AC power grid. That power would get dumped into a little reservoir (an electrolytic capacitor.) The amount of energy in the capacitor would fluctuate when the AC power fluctuated but it would not drop to zero. To eliminate flicker, you would then operate a second circuit (stage 2) that could keep the LEDs perfectly and steadily lit using the capacitor as its power source. This scheme works because the capacitor always has some energy available even when the AC input power drops out. Bye-bye flicker.

The two-stage solution worked but it ran too hot. Each electronic stage converts power with a certain efficiency. The lower the total efficiency, the hotter the lamp. When you cascade two stages together, you multiply the efficiencies together. Suppose you had two stages that were each 90% efficient and you had a minimum allowable efficiency of 85% before the lamp would run too hot. Two stages in series would result in only 81% efficiency. For the Soraa MR16, 81% wasn’t good enough. A solution to increase the efficiency had to be found- and it was.

Complexity unleashed – multidimensional control systems, just like an airplane . Ordinarily in a two-stage circuit, each stage minds its own business- stage 1 keeps the capacitor topped off and stage two runs the LEDs but the two stages don’t ever talk to one another. But to increase the efficiency to acceptable levels, stages 1 and 2 would have to cooperate to manage the energy in electrolytic capacitor. This is similar to how an airplane maintains level flight. If you move the rudder, the ailerons will also need an adjustment to maintain level flight. This multidimensional control solution gave the needed efficiency but it became complex enough that the circuitry no longer fit into the lamp.

Complexity tamed – enter the Digital LED driver, just like a jet fighter Soraa’s engineers had dealt with this type of complexity before and knew that the solution was to go digital. Using software to control the lamp’s electronic stages, the complexity can increase without making new changes to the physical circuit. This is exactly how jet fighters evolved to expand their flight envelopes. Multidimensional digital control systems could allow the jets to do more; digital power conversion would allow the Soraa MR16 to do more too.

All digital all the time - Unexpected benefits It’s only after you embed the power of a programmable controller into a product that the full force of what you’ve done hits you. Soraa’s Digital MR16 started off as the manifestation of a stubborn determination to produce perfect light. But it’s shaping up to be the most capable and versatile lamp in our lineup. Ordinarily when your colleagues come to you and ask “can the lamp be made to work with this or that transformer or dimmer”, you tell them “maybe.” Now the answer is almost always “yes.” But it’s not just broader compatibility, its broader capability. Here’s a small sampling of what your Soraa Digital MR16 is doing while it happens to be producing the world’s best light:

-

It’s keeping and remembering statistics on how it’s been operating.

-

Total operating time, number of starts, thermal history and more

-

It knows whether its on AC or DC power and always does the right thing

-

It’s monitoring and managing the health and lifetime of its electrolytic capacitor

-

It’s running as cool as possible (at maximum efficiency) without sacrificing light quality

-

Its standing ready to report on its status and even get updates to its programming

Those of us who use computers and smartphones have come to expect upgrades in capability through new firmware or software. Soraa is actively bringing this paradigm to its product line with attendant increases in capability and reliability while reducing production costs.

It doesn’t often happen that the solution to a specific technical problem profoundly changes the way we look at an entire product line. At Soraa we’ve made the switch to digital lighting in our factory; but more importantly we’ve made the switch to digital technology in our thinking. We can’t imagine doing it any other way.