Top LED material manufacturer Dow Corning showcased a prototype silicone-based material for UV LED applications at the biennial Light+Building 2016, which takes place this week at Frankfurt Fair and Exhibition Center in Germany.

Silicone’s flexible properties has given LED manufacturers more freedom in LED design, but has not been the common choice in UV LED designs, which has mostly been using glass-based optical designs especially in the Deep UV (DUV) LED applications. Few materials are robust enough to withstand harsh environments that UV LEDs often are subjected to, for instance in water purification or other applications.

|

|

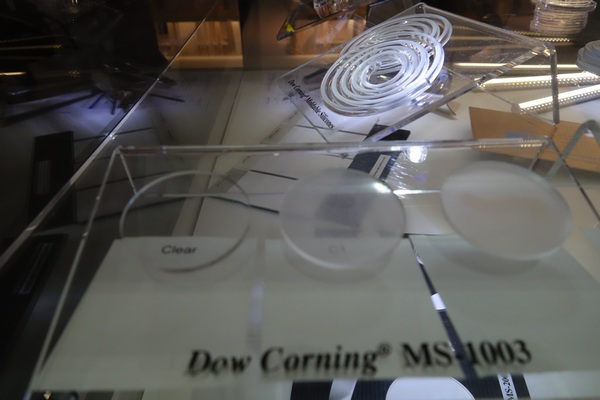

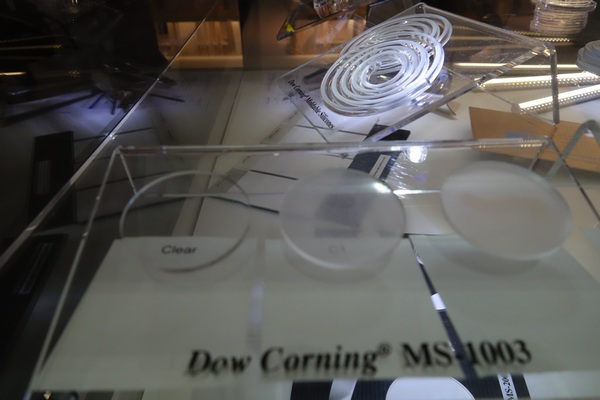

Dow Corning solutions for optical lens. (All photos courtesy of LEDinside) |

Dow Corning, though, is challenging this concept with its prototype silicone-based secondary optics for UV LED applications with the prelaunch of MS-4002 at the show. The material is still being tested for DUV applications, and even though ight transmission rates of the prototype product are still below the company’s general lighting secondary optics (which typically have a 95% to 97% light transmission rate), it is still delivering a good performance, said Hugo da Silva, Global Industry Director, LED Lighting, Lighting Solutions, Dow Corning.

With more UV LED applications emerging on the market, such as water disinfection, germ sterilization and others, the company has started to work on UV LED material after receiving growing number of inquiries from clients, he added. The company plans to launch new secondary optical lens for UV LED applications sometime later this year, but details of the products are confidential. Despite these positive developments, da Silva held a conservative outlook on future UV LED market growth. “This won’t be a very high volume application,” he said. “Not a lot of value for UV LED.”

|

|

Hugo da Silva, Global Industry Director, LED Lighting, Lighting Solutions, Dow Corning. |

In his opinion, UV LED will remain mostly a niche market, where trends and performance will be similar to OLED sector, where the technologies will only be used in specialty markets, he explained. Compared to general lighting or display markets, UV LED is still much smaller than general lighting or display markets. Moreover, chip pricing will remain a huge challenge for UV LED manufacturers. “UV chip price will never be the price as it wants to be, the same as OLED,” commented da Silva.

Dow Corning highlights lighting solutions at Light+Building 2016

Aside from its secondary optic lens products for UV LED applications, the company was also highlighting a new range of moldable optical silicones, optical encapsulents, and new technology optical films, diffuser technology. Compared to other regional lighting shows, Dow Corning’s focus at Light +Building 2016 is centered on end-market lighting and luminaire applications. “Typically in shows like in Japan, China, Korea, or if you go to Taiwan, we focus a lot on LED packaging material,” said da Silva. “Most of our clients are in Asia. Or should I say all the customers are manufacturing in Asia, and some of them are in Europe, but we use this show to showcase our more downstream products.”

|

|

|

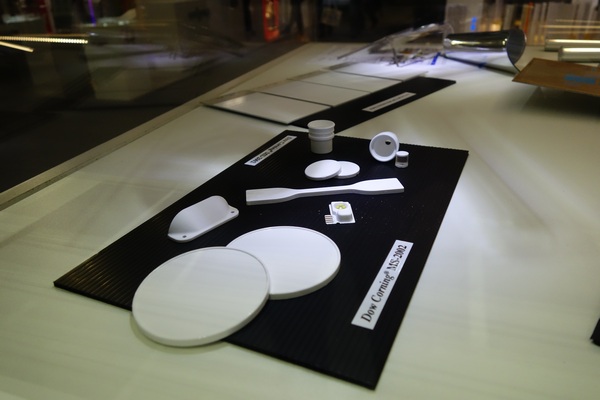

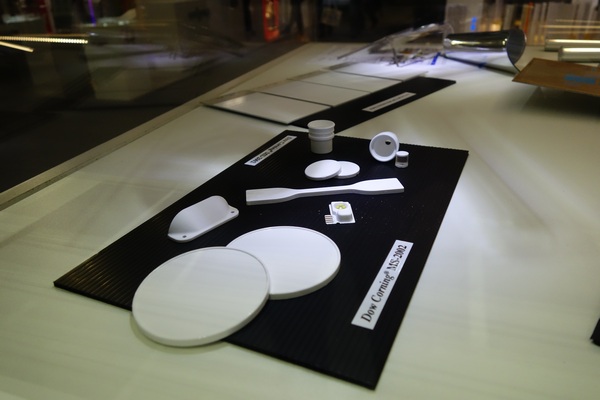

Top: Dow Corning Moldable Silicone solutions. Bottom: Moldable silicone material Dow Corning MS-1003. |

What to expect after Dow Chemical’s merge with Dupont?

Formerly a joint venture between Dow Chemical and Corning, Dow Corning became a wholly owned subsidiary of Dow Chemical on December 2015. Dow Chemical, which holds a 50% stake in the silicone material manufacturer, acquired the remaining 50% from Corning for US $4.8 billion. Earlier in the same month parent company Dow Chemical announced it will be merging with DuPont to become DowDuPont, which has changed the dynamics of the material industry.

So what to expect after the merge of the world’s two largest material companies? “There is no change at the moment,” according to da Silva. There will be no changes in the product portfolio, customer interface roles, and things are operating as usual, he added.

|

|

|

Top: Dow Corning MS-2002 moldable silicone white reflector. Bottom: Dow Corning foldable silicones. |

DowDuPont has not announced how the three material companies will function as a single entity yet, for the time being they will operate as independent entities. However, da Silva envisions the group will be moving towards becoming a total solution provider, where the three companies’ products are complimentary of each other. Dow Corning’s optical material and liquid interface materials combined with Dow Chemical’s LED packaging products, and DuPont’s strengths in lighting luminaire designs using different materials from Dow Corning, thermal interface materials and fabricate thermal interface materials.

|

|

Dow Corning booth at Light+Building 2016 seen from afar. |

“Interestingly, the product portfolio between the three companies are not competing products,” said da Silva. “If the portfolios are combined it will be very complete from all sides of the supply chain.”

Following the merge between Dow Chemical and DuPont, it will be interesting to see the new direction Dow Corning will take. Moreover, developments in the UV LED sector might lead to more interesting product developments in the near future, where Dow Corning may provide a wider selection of flexible silicone secondary optical lens for this particular sector.

(Authors: Roger Chu, Research Director, LEDinside and Judy Lin, Chief Editor, LEDinside)