(Author: Joanne of LEDinsidehttp:// Translator: Judy Lin, Chief Editor, LEDinside)

In this article LEDinside will address market opportunities observed for UV curing applications at RadTech UV+EB 2016, which took place a week ago in Chicago, U.S. In this series LEDinside has covered UV LED package, epoxy resin, photoinitiator, related materials, and module applications.

LED curing market opportunities: Wide range of product applications upgraded to meet market demands

UV LED curing market applications include food packing, wood coating, adhesive coating, medical coating and others. There are also many curing application markets and emerging markets which hold great growth potential.

Challenges in curing market applications, which mainly include curing coatings and thermal dissipation designs

Challenge 1: UV curing coatings

Curing coatings include oligomers, polymers, photoinitiators, monomers and other adhesives, oil-based ink, matting powder, and fillers.

The desired curing effect depends on the application requirements, for instance food packing requires low migration to ensure the food is safe from toxic substances, it also requires curing to reach a certain strength, flexibility, uniformity or quick coating effect. Wood coating also requires a natural finish and appearance after curing.

When curing in the air, oxygen in the atmosphere can cause a phenomenon known as oxygen inhibition, which can cause oxygen to inhibit the cure on the surface layer of the polymerizing layer. This can cause the top layer to become uncured sticky and wet, while the bottom layer might have cured and hardened into a dry finish. This can affect the coated layers long term reliability, and even effect the hardness, gloss, and scratch resilience of the finished coated layer.

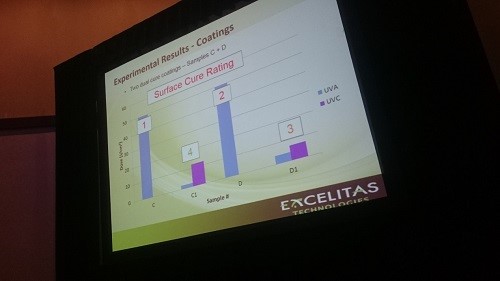

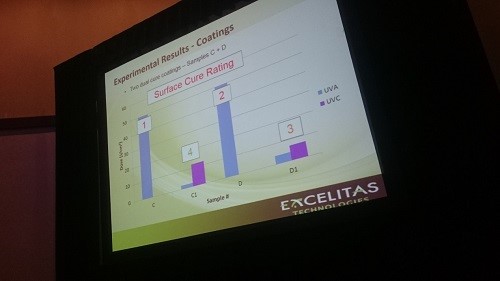

Most material manufacturers are striving to reduce oxygen inhibition in the UV coating, by using UV-C LED products. However, there are still issues including UV-C LED efficiency, product lifetime, and compatibility with UV-A LED products, and meeting curing market demands that manufacturers are still trying to solve. UV-C LED manufacturers EXCELITAS, SolidUV/ PlayNitride have developed products based on the above concept.

|

|

Excelitas UVA and UVC surface cure ratings. (All photos courtesy of LEDinside) |

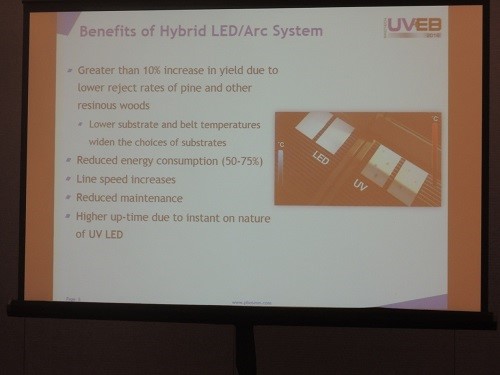

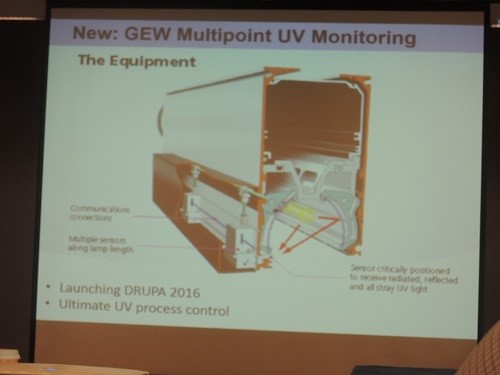

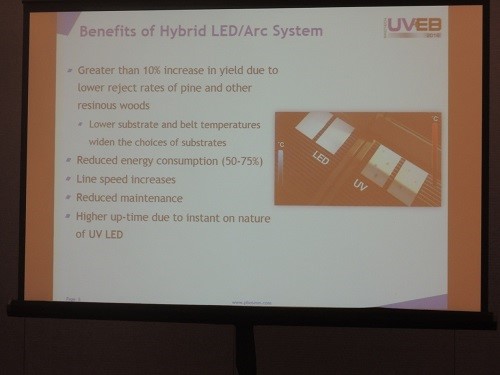

A current challenge is UV LEDs efficiency have still not met curing market demands, which has to be compensated with another system design. During the forum at RadTech 2016, speakers from GEW and Phoseon both mentioned ArcLED hybrid solutions, which integrates traditional UV light sources with UV LEDs. By combining the advantages from the two light sources, this can cancel its flaws.

|

|

|

Top: GEW representatives explaining ArcLED systems to visitors at RadTech 2016. Bottom: A powerpoint slide explaiing how the ArcLED system works. |

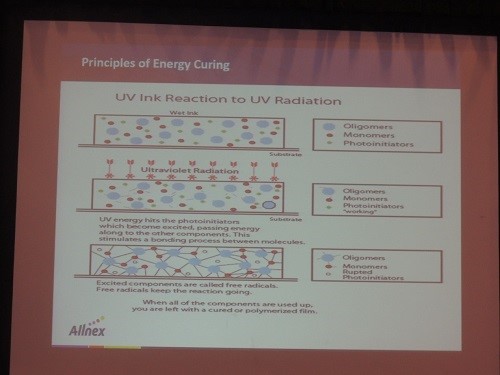

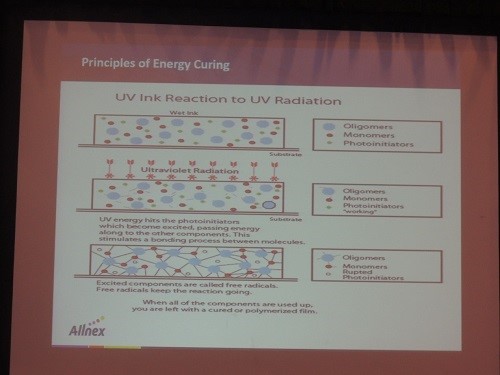

Another method involves increasing the monomers in the ethoxy group of the curing material to reduce oxygen inhibitors. Allnex’s main products include LED01, LED02, and EB85 (which is mainly applied in the printing market).

|

|

|

Top: Allnex representatives introducing their products to the public. Bottom: Allnex's power point slide on UV ink reaction to UV radiation. |

Challenge 2: optical and thermal design

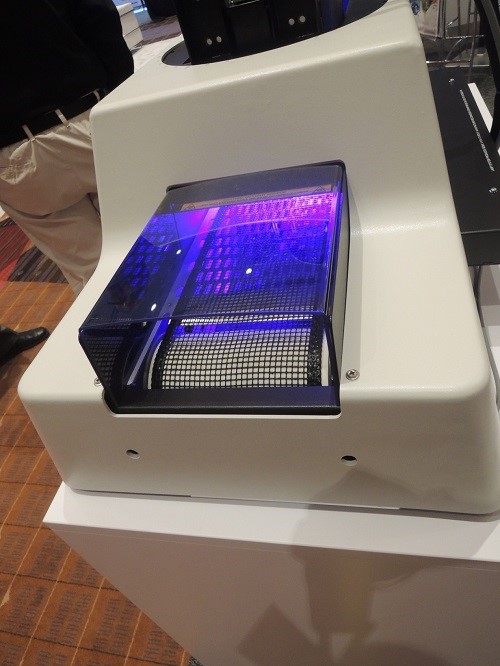

In optic designs the challenge is how to optimize the design so it can reach peak irradiance and meet clients’ luminous intensity, irradiance, and uniform light output demands. KOPP’s new UV glass optic design improves mixing wavelengths from multi-UV LED array that can reach similar spectrum performance as mercury lights. The glass lens specialist is currently patenting the product.

|

|

Kopp Glass booth at RadTech 2016. |

Compared to optic designs, many manufacturers still lack thermal dissipation solutions. A comprehensive optic, thermal, and mechanic solution can be provided to equipment manufacturers by combining UV LED optic designs with cooling system designs. Based on LEDinside’s observations, most manufacturers are still using air-cooled thermal dissipation tube designs, while water cooled system using water cooling tube systems are suitable for high wattage applications.

Challenge 3: Lack of uniform standards for measuring UV LED module specs

There are different standards for measuring UV LED module sizes, which mostly depends on the end market client demands and comprised of customized products. Optic designs are primarily focused on long operating distances to reach the peak irradiance requirements, flexible optic designs, and providing clients different operating distance products. Manufacturers are striving to develop products that can meet clients’ light intensity and irradiance requirements.

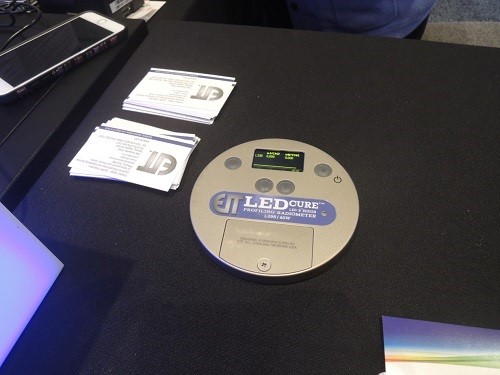

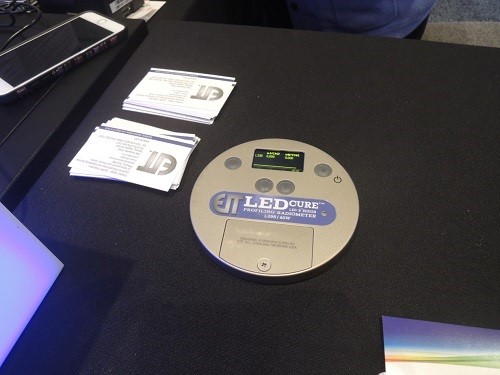

EIT’s L395 unit can be used to measure optic response in the 370-420 nm wavelength range, determine the operating distance, irradiance and energy intensity based on the wavelength peak.

|

|

EIT’s L395 unit for measuring optic response in the 370-420 nm wavelength range. |

Global leading UV LED light source, module and system manufacturer Heraeus has released new light source system Semray, which has advanced module design and made significant breakthroughs in UV LED customization. It can also be used as a replacement light source concept in the UV curing market.

|

|

|

Top and bottom: Heraeus UV LED products for curing applications. |

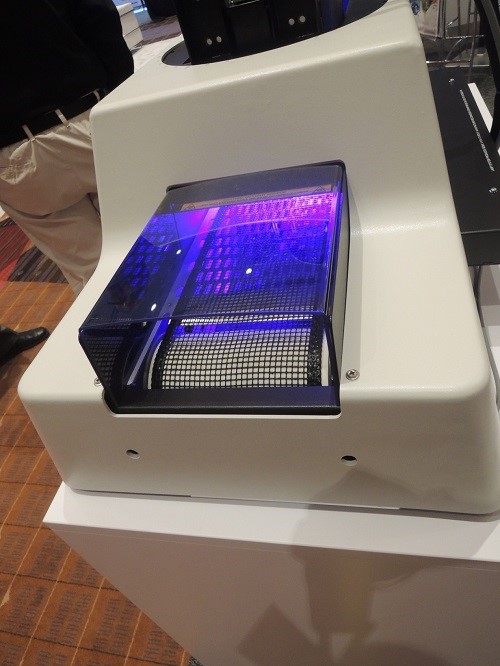

Hamamatsu is a leading LED chip, LED package, light source, and system equipment manufacturer that integrates air cooling systems with container printer devices. The company has also released UV LED products for oil-based printing and high speed printing applications.

|

|

Hamamatsu UV LED products for printing applications. |

Heraeus, GEW and Digital Light Lab’s light source control system can use smart connected technology or manual methods to adjust the light source’s brightness, conveyor speed, and is beneficial to the UV LED curing monitoring process.