(Author: Judy Lin, Chief Editor, LEDinside)

Earlier this week, UV LED specialist RayVio’s CEO Robert Walker spoke to LEDinside about the company’s outlook for the UVC LED sector, and their current market strategy.

RayVio’s new UVC LED product targets water and surface disinfection

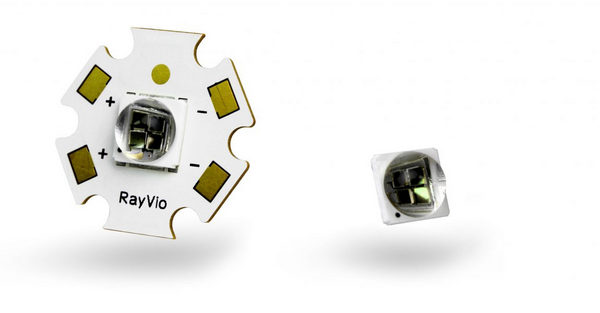

The company’s latest UVC LED product for hygiene and water disinfection applications launched on May 18, 2016 is a new 6.5 mm SMD UVC LED.

Designed especially for hospital and water disinfection purposes, the chip is capable of delivering 40 mW at 100 mA in a single package. The UV LED emits a wavelength of 280 nm-290 nm, which can deactivate DNA of bacteria, viruses, and other pathogens.

|

|

A RayVio UV LED emitter. (Photo courtesy of RayVio) |

Asked why the 6.5 mm spec was preferred over 6.8 mm for the UVC LED package, Walker explained it was to maintain thermal characteristic, and the size was appropriate for driving the chip to 40 mW.

The compact UV LED product, which uses a quartz lens, can be used for both portable and standard disinfection equipment, said Walker.

The company’s current UVC LED chip technology is sapphire-based, and uses a buffer layer comprised of aluminum nitride (AlN) or aluminum gallium nitride (AlGaN).

“We will continue to make different wavelength products,” said Walker.

DUV LEDs will be high on the company’s R&D agenda in the future, but Walker declined to comment on specific product roadmaps, such as the time table for 260 nm UV LED product release, saying it was confidential information.

Water and hospital disinfection UVC LED requirements

Depending on the type of germ or bacteria that needs to be eliminated, UVC LED performance requirements will vary.

For water disinfection applications, the power required to drive the UVC LED or watts to be driven completely depends on water volume and flow rates. “Usually, 5 mW, 10 mW and 15 mW is enough power for disinfection,” said Walker. Another factor to take into consideration is the type of germs that need to be killed, typically UVC LEDs used in water disinfection are especially efficient at killing E.coli and shigella.

Water disinfection UVC LEDs have a slightly lower germ kill rate requirement of 99.5% compared to hospitals kill rate requirement of 99.99%. UVC LEDs can also be very handy at killing superbugs in hospitals and preventing the spread of antibiotic resilient bacteria, such as clostridium difficile (C.Diff) and Methicillin-resistant Staphylococcus Aureus (MRSA), said Walker.

Disinfection is just the first step for RayVio UVC LEDs

In the short term, RayVio’s UVC LED products will be primarily focused on disinfection of surfaces, hospital hygiene, and water disinfection, said Walker. He went on to project air disinfection, food and horticulture, where large growth potential is expected from plant grow light applications will take off next. Industry curing was placed last.

Curing still presents a high technology threshold for most UVC LED manufacturers. “This is mainly because most UVC LEDs are not efficient enough to meet curing requirements,” explained Joanne Wu, Assistant Research Manager, LEDinside.

RayVio plans to launch water disinfection products during second half of 2016, with most products entering volume production, said Walker. It is also working with customers to develop UV curing related products.

A new round of funds totaling US $26 million that RayVio received from Chinese investors IPV Capital and Tsing Capital is expected to support the company’s future developments. “The US $26 million funding is mostly for ramping up production for UV LED, accelerating product development, and support downstream partners,” said Walker.

The company in-house develops EPI-wafer package, but cooperates with system integrators, and forms partnerships with OEMs to ramp up production. RayVio’s downstream manufacturing relies on visible LED structure to scale up production, added Walker.

RayVio’s leading UVC LED technology for disinfection applications is expected to gradually proliferate to other applications one step at a time, and with sufficient funding the company is reading itself for mass production.