Leveraging its leading expertise in chip scale packaging, Lumileds today introduced the LUXEON UV U1 LED for use in UV curing, counterfeit detection, analytical instrumentation, inspections and other UVA and Violet (380-420 nm) applications. This third generation of UV LEDs maintains the same micro package size as LUXEON Z UV, but enables a higher power density. LUXEON UV U1 also features a robust design that eliminates materials like silicone over mold, which tends to yellow and crack upon UV exposure, and the elimination of wire bonds that can lead to catastrophic connection failures. “UV LED customers are reliability driven. They tend to run their equipment 24/7 and demand a proven product that will perform as expected for over 20,000 hours. The LUXEON UV U1 is that reliable product,” said Yan Chai, Product Line Director of Lumileds UV LEDs.

|

|

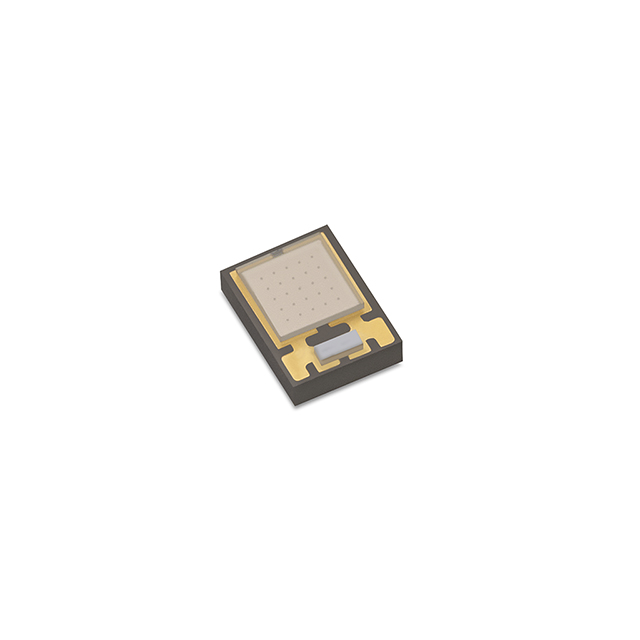

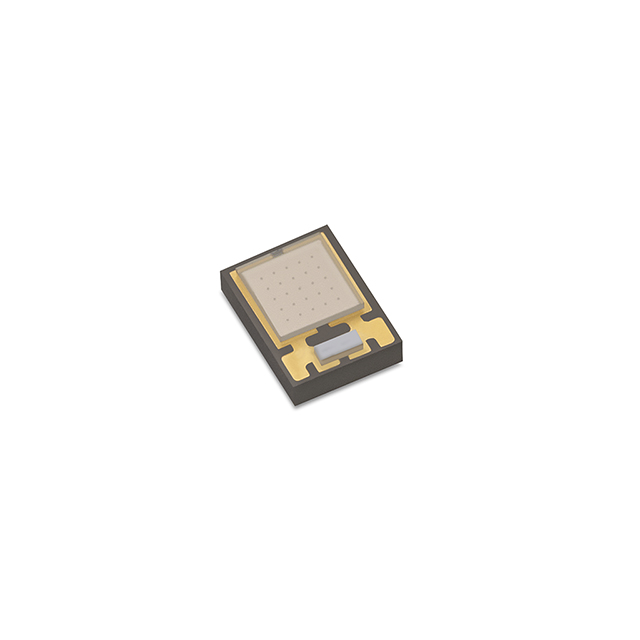

Lumileds LUXEON UV U1 LED seen from an angle. (Lumileds/LEDinside) |

The LUXEON UV U1 LED is nominally tested at 500mA but can be driven at up to 1A to achieve higher irradiances. For the application of UV curing at 395 nm, LUXEON UV U1 achieves 700 mW at 500mA and >1300 mW at 1A under 25oC. Compared to the 3.5x3.5 mm2 package size of most UV LEDs, LUXEON UV U1’s unique micro package size delivers superior packing density as well as >5X higher power density. The LUXEON UV U1’s footprint is a drop-in replacement for the LUXEON Z UV, while providing twice the typical radiometric power as its predecessor at 380-390 nm, a popular range for UV curing applications. The surface mount LEDs can be tightly assembled with spacing as small as 200 µm for high system flux density. With a wall plug efficiency exceeding 45+% and thermal management aided by an AlN package, users can avoid the use of more expensive water cooling at the system level.

|

|

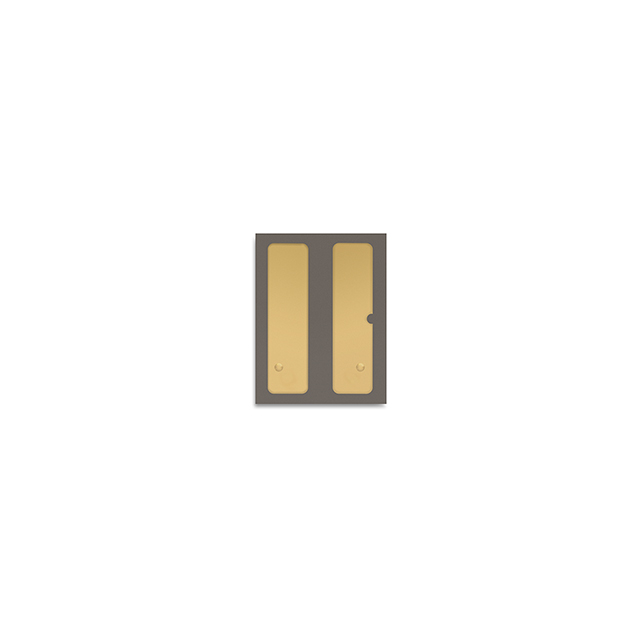

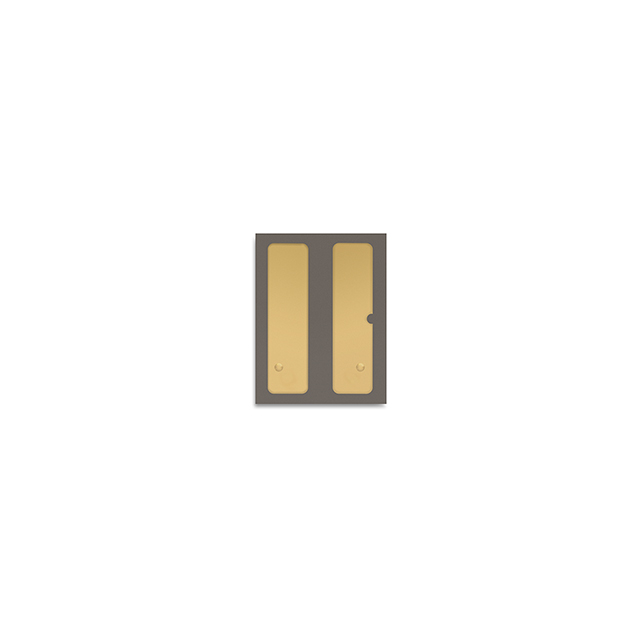

The back of Lumileds LUXEON UV U1 LED. (Lumileds/LEDinside) |

To learn more about the LUXEON UV U1 emitter, see www.lumileds.com/LUXEONUVU1.