High Power Lighting (HPLighting) is a major UV and IR LED vendor. Over the years, HPLighiting has worked closely with chip vendors and focused on LED packages and optical design. The company has successfully developed UV and IR LEDs based on its competitive advantages. At OPIE’17, LEDinside interviewed Charles Wei, General Manager of HPLighting, to learn about HPLighting’s progress of UV and IR LED technologies.

According to Charles, HPLighting would demonstrate three product and technology solutions including a 270nm-275nm UV-C LED for sterilization and purification, an IR LED for iris and facial recognition, and a UV-A LED for high speed printing.

Demonstrated Product 1: 270nm-275nm UV-C LED for Sterilization and Purification

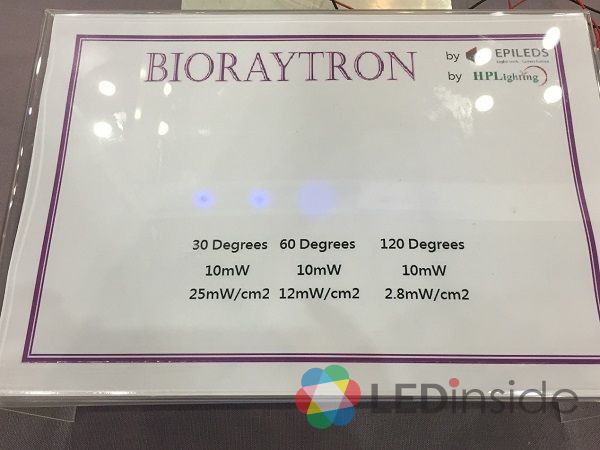

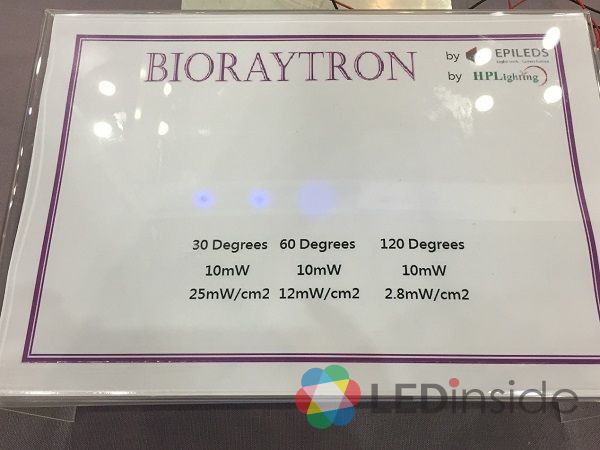

EPILEDS is a UV and IR LED chip vendor and HPLighting is a package and module manufacturer; both have high hopes for the Deep UV (DUV) market. As a result, the two companies formed a strategic alliance three years ago to establish a DUV supply chain in Taiwan. In late 2016, EPI LEDS and HPLighting launched the Bioraytron joint venture to promote vertical integration of DUV LED applications. Starting from the manufacturing of epitaxy and LED chips, the joint venture focuses on the sales of UV-C LED packages and modules.

Currently, UV-C LEDs can operate at wavelengths between 270nm-275nm. Sampling of 10mW @ 150mA products has been completed with small-volume shipment underway. New products have been scheduled for release in the third and fourth quarters of 2017. Development of 20mW products has ended with sampling expected to begin in the third quarter; 30mW products are said to be completed in the fourth quarter. The rapid progress is ascribed to the mutual-trust and collaboration between EPI LEDS and HPLighting.

HPLighting says its target markets are air cleaners and water purifiers. Capitalizing on unique optical design, HPLighting has developed products with a beam angle of 60 and 30 degrees for higher efficiency. The products can provide stronger radiation intensity at a smaller angle, possessing more market value than 120-degree counterparts.

Bioraytron is planning to roll out second-generation UV-B/ UV-C LED packaging technology in the second half of 2017. By integrating enhanced optical design with chips and packages, the technology can provide different beam angles and light patterns, allowing customers to use the LEDs for various sterilization applications and skin treatment more easily, thus accelerating commercialization of the products.

LEDinside has noted that, unlike other vendors driving the LEDs at higher current levels to increase light output, HPLighting has adopted low current to keep the heat within customers’ tolerance in order to increase market adoption.

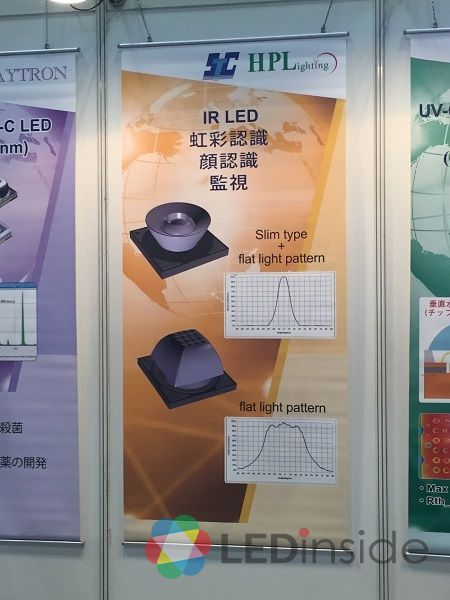

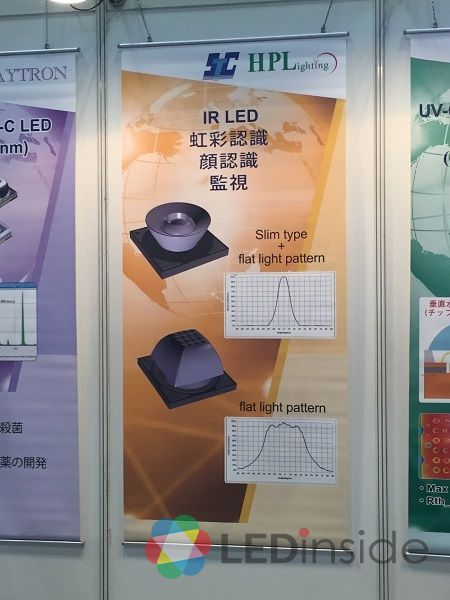

Demonstrated Product 2: IR LED for Iris and Facial Recognition

HPLighting says, the IR LED featuring quartz optical lens uses first optical design to provide a special form factor. Once the light source is concentrated, the plane light will be radiated onto the human face evenly to facilitate facial recognition. First optical design is complicated and the technological barriers are extremely high. Currently, the LEDs can be slimmed down to 2.4mm and 1.6mm, offering great design advantages for camera modules and camera brands. The IR LED has been introduced to notebook PCs. In the future, as costs decline dramatically with mass production, LEDs with a higher price/performance ratio will be available.

Demonstrated Product 3: UV-A LED for High Speed Printing

While other vendors have increased radiation intensity by reducing illumination area using modules, HPLighting can offer radiation intensity for over 8W/cm2 at less than 100mm. As a result, the LED can meet the radiation area requirement of the print format and high speed printing. The heat dissipation problem is also solved with the use of quartz glass packages and copper substrates. Simply assembling each COB LED and fastening them together with screws, the customer can provide a UV module with a width of 1000-1100mm or even 2000mm for high speed printing applications. HPLighting has formed partnerships with several well-known Japanese printing module vendors.

Apart from optical modules, HPLighting has worked closely with Setsuyo, a subsidiary of Mitsubishi Electric Corporation, for its heat sink solutions. Setsuyo is also HPLighting’s distributor for the Japanese market.

Charles Wei says, HPLighting will continue to enhance its packaging technology and optical design for invisible light LEDs. Besides using quartz glass and copper substrates to ensure stable quality, HPLighting will tighten the ties with its enterprise partners to address market and customer needs.

(By Joanne / LEDinside)