Latest results from IEMN show more than 1400 V breakdown voltage for both vertical and lateral measurements on ALLOS’ upcoming GaN-on-Si epiwafer product for 1200 V devices.

A team around Dr. Farid Medjdoub from IEMN research institute in France has made devices and conducted measurements on two different GaN-on-Si epiwafer products supplied by ALLOS Semiconductors of Germany. One is a prototype of ALLOS’ upcoming product specifically designed for 1200 V device applications. With this epiwafer IEMN achieved over 1400 V for vertical and 1600 V for lateral (grounded) breakdown. The other epiwafer is ALLOS’ established product for 600 V applications which equally showed very high breakdown voltages of 1200 V and more for both lateral and vertical measurements.

The new epiwafer product for 1200 V device applications is from an ongoing internal development program at ALLOS. Its strong performance results from an innovative structure combining ALLOS’ unique strain-engineering and high crystal quality approach with additional measures to suppress leakage and enhance breakdown voltage further. This was achieved without compromising on other essential parameters like crystal quality or wafer bow and without introducing carbon-doping. Epi growth was conducted on a standard Aixtron G5 MOCVD reactor.

Already at the International Forum on Wide Bandgap Semiconductors (IFWS) in Beijing in November 2017 ALLOS showed device results from an industry partner using ALLOS’ 600 V epiwafer. With a mature device design and measurement setup for up to 1000 V leakage values of 0.003 µA/mm² at 600 V and of 0.033 µA/mm² at 1000 V were achieved. “This feedback by our partner was great news for us as it was another confirmation for the capability of our technology for 600 V applications” explains Dr. Atsushi Nishikawa, CTO of ALLOS. “Now the big question was at which voltage above 1000 V the physical breakdown occurs and whether we are on track with our development in the 1200 V domain too.”

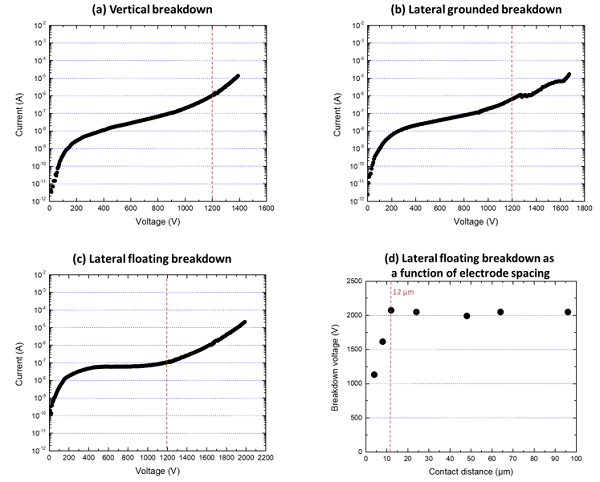

The answer is now available with the results shown by IEMN. It used simplified device design and processes allowing a much faster feedback than from an industrial process. On a prototype of ALLOS’ new epiwafer product for 1200 V devices IEMN achieved more than 1400 V for vertical and 1600 V for lateral (grounded) breakdown voltage (Figure 1 (a) and 2 (b) respectively). Supplementing characterization with a floating measurement setup resulted in a lateral breakdown of more than 2000 V with 12 µm contact distance (Figure 1 (c)). Saturation of lateral floating breakdown occurred at 12 µm contact distance for the 7 µm thick epi-stack with breakdown already more than 1100 V for 4 µm contact distance (Figure 1 (d)).

|

|

Figure 1 (a) to (d): Results from IEMN on ALLOS’ epiwafer technology for 1200 V application. (Image: ALLOS Semiconductors)

|

Putting these results into perspective Dr. Farid Medjdoub from IEMN explains: “With over 1400 V for vertical and 1600 V for lateral breakdown with substrate grounded ALLOS’ epiwafer favorably compares to all the samples we have measured so far from various industry and research partners. Furthermore, the results we have seen indicate that the device performance is very uniform over the wafer, which is a very important characteristic to qualify for actual device production.”

On ALLOS’ 600 V epiwafer product IEMN achieved 1200 V for vertical and 1500 V for lateral (grounded) breakdown voltage. Both epiwafer products are not doped with carbon, which is often used by GaN-on-Si makers to enhance isolation but has negative impacts on crystal quality and dynamic switching behavior. Both products are available with 675 µm thickness for 150 mm wafer diameter and 725 µm thickness for 200 mm. Bow for all ALLOS epiwafer products is tightly controlled at below 30 µm.

“The results now available show that we are already at 1.7 MV/cm laterally and 2 MV/cm vertically – and we have a program to realize further improvements on epiwafer-level. Now is the time to establish a strong partnership with an industrial partner also in the 1200 V product range.” says Burkhard Slischka, CEO of ALLOS. “As we are a pure epiwafer technology provider without own device making we are seeking a close cooperation with an experienced power electronics player to exploit the opportunities for their 1200 V GaN-on-Si based applications. With our technology GaN-on-Si has the potential to effectively compete with SiC performance at a fraction of the wafer cost.”