The Foxconn Group has continued to accelerate Micro LED development by several subsidiaries including eLux, Inc. LEDinside had an opportunity to visit eLux and learn about the current progress of the Micro LED technology development. Before joining the Foxconn Group, Jong-Jan Lee (J.J. Lee), CEO of eLux and Paul Schuele, CTO of eLux, have both worked at Sharp Laboratories of America and established eLux to develop Micro LED technology. After being acquired by Foxconn, eLux has cooperated with other companies under the Foxconn Group and achieved some breakthroughs in creating Micro LED displays.

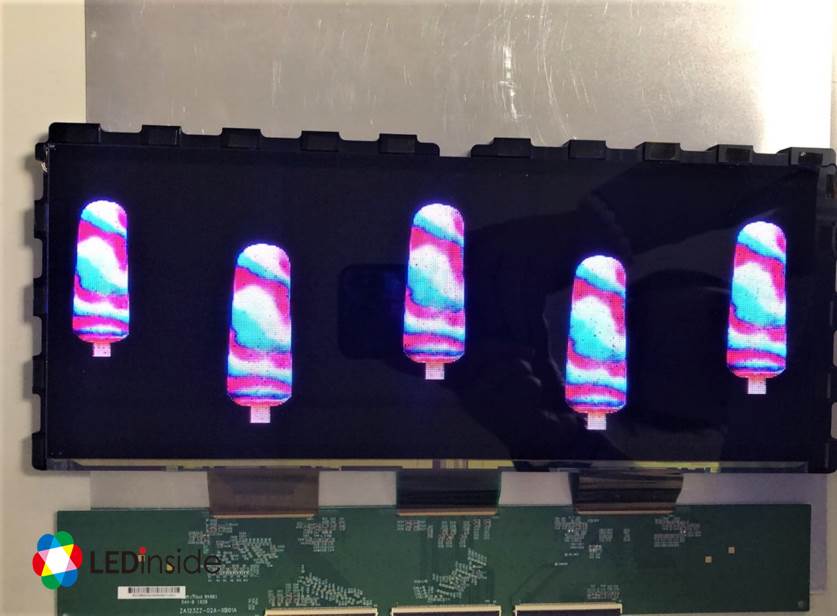

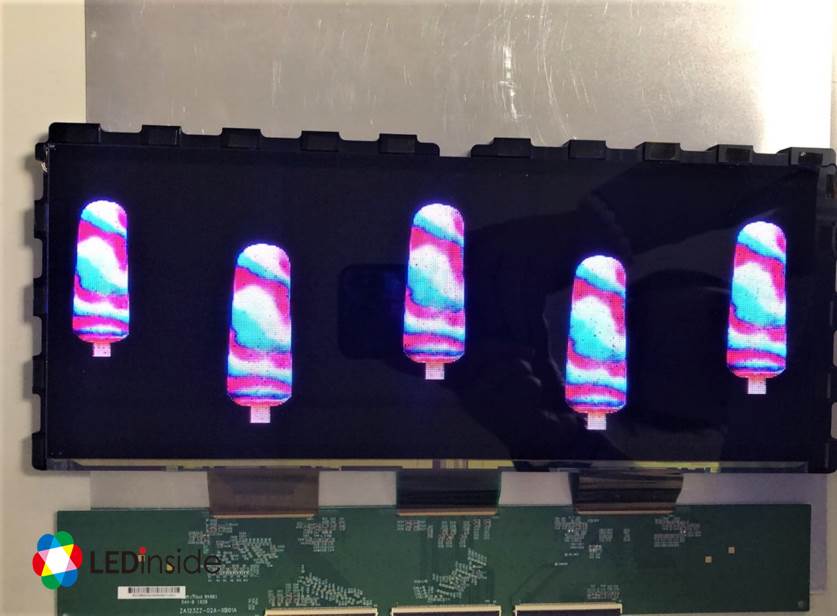

LEDinside was pleased to interview J.J. Lee to gain some insight into Micro LED technology development. Lee showcased a 12-inch full color Micro LED display to illustrate the on-going progress. The display applied an actively driven LTPS backplane solution with a pixel density of 42 ppi and a brightness of over 1,000 nits, delivering excellent performance with high contrast and full color. The company has also achieved a Micro LED display with 168 ppi resolution using the same technology. Lee indicated that eLux has overcome the technical barriers and is capable of producing RGB full color displays with its proprietary fluidic assembly solution, which enables significant cost reduction. As a result, Micro LED displays can be more cost-effective and competitive with the assembly solution developed by eLux.

eLux 12-inch full color display

The key to realize commercial production of Micro LED display: cost-effective fluidic assembly technology

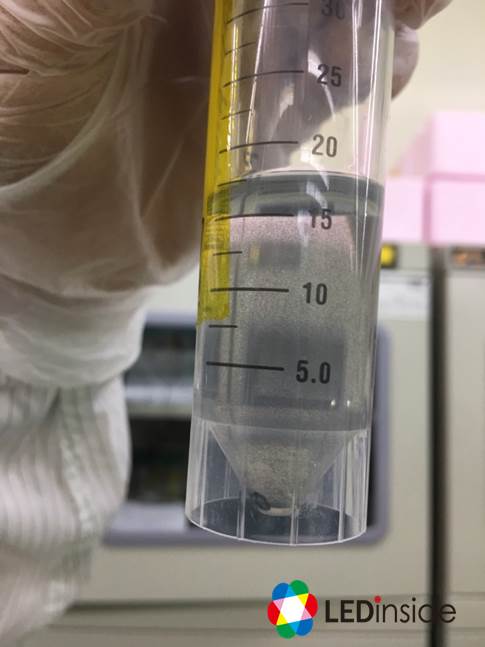

The fluidic assembly technology of eLux uses a carrier liquid to transfer Micro LED chips onto the TFT backplane and assemble them in position for each pixel. The transfer process uses more Micro LED chips than required for the number of pixels and the left-over chips and fluid can be recycled. By using micro-PL and defect inspection during the chip process, the method will only harvest good chips in the fluid. With the defect chips screening process, the utilization of Micro LED chips can be nearly 100%. Unlike common pick and place or laser transfer methods that need to discard whole wafer area that contains about 0.1%-0.01% of bad chips, the fluidic assembly technique requires less consumables and thus costs less.

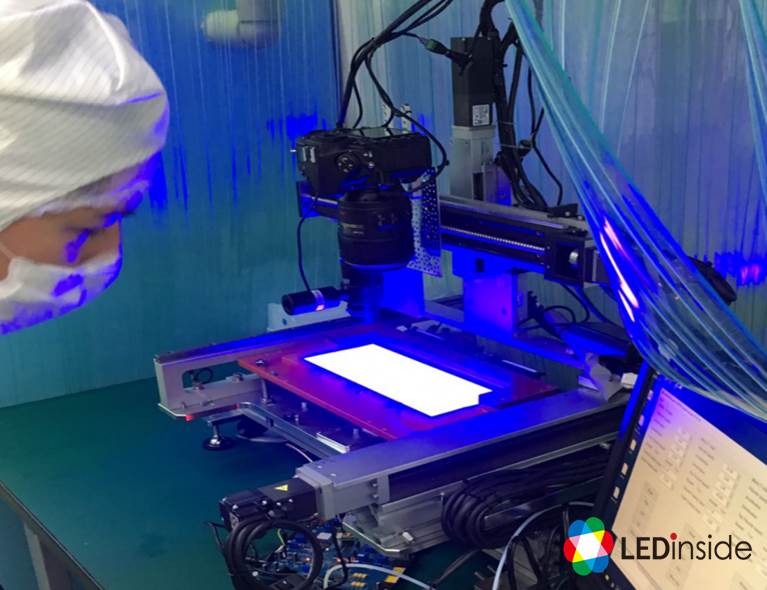

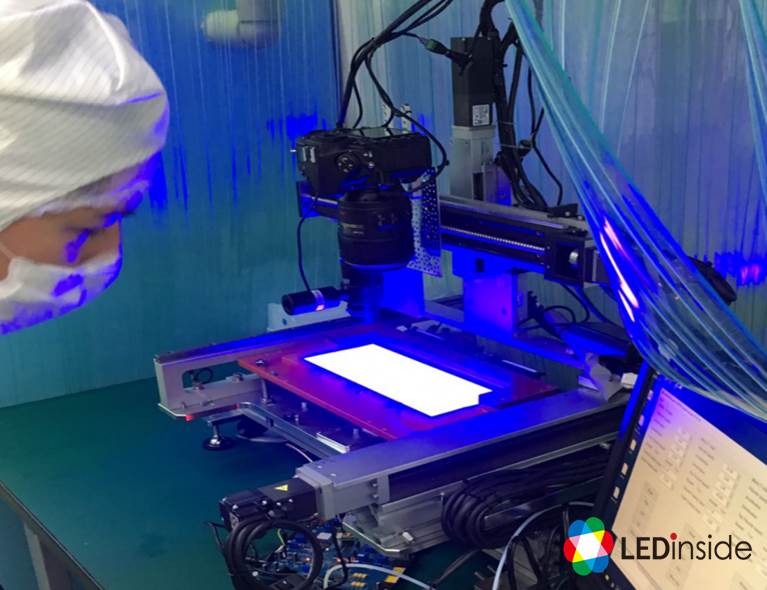

In terms of transfer equipment and process, the fluidic assembly is a self-alignment process so it does not need explicit control of chip alignment. Therefore, equipment cost is relatively economical and the price of an automatic assembly tool for 12-inch substrates would be around US$100 thousand. It takes only 15 minutes to assemble a 12-inch Micro LED panel for both a 42 ppi display, which includes 518,400 LEDs and a 168 ppi display with 8,294,400 LEDs. The fast assembly method and low-cost equipment make the production cost of eLux Micro LED display very competitive.

Moreover, Micro LED chip orientation can be precisely controlled with a unique feature built on the chip. Since it is a self-alignment process, the pitch of the Micro LED is not limited by the accuracy of transfer equipment. eLux has demonstrated the fluidic assembly on Micro LED size down to 20 μm, the proprietary fluidic assembly technology can cost-effectively manufacture high resolution panels for 4K and 8K display applications.

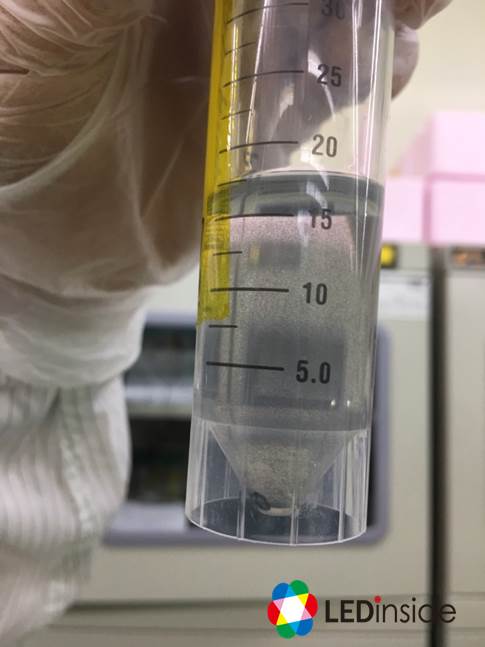

2.5 million Micro LEDs harvest from a 4-inch LED wafer in liquid

Extremely high epi wafer utilization rate using fluidic assembly

Furthermore, the common pick and place method requires strict wavelength uniformity of the Micro LED epitaxial wafer because small color differences produce a visible mosaic pattern on the Micro LED display. The fluid assembly technique randomly distributes Micro LED chips with different wavelengths, which avoids the mosaic pattern. For Micro LED signage with larger size and longer viewing distance, the wavelength uniformity for Micro LED wafer can be about 10 nm, which alleviates the stringent requirement for MOCVD tool and increases the utilization of LED wafers.

According to Lee, production cost and efficiency is the key to commercialize Micro LED display production and the eLux fluidic assembly technology is definitely a critical process for the next generation of display technology.

Fluidic assembly improves the uniformity of Micro LED displays

Learn more about the latest technology development and on-going industry trends of Micro LED with LEDinside. Our annual Micro LEDforum event will gather worldwide industry leaders and experts to presents comprehensive analysis on key market trends, ranging from manufacturing equipment, chip design, testing solutions, transfer techniques, driver design, display and niche technological products.

Register now to enjoy the final chance of early bird discont! Event link: https://seminar.trendforce.com/LEDforum/2019/US/INDEX/

Author: LEDinside Roger / Max / Simon