LED filament cooling finally has solutions! LED filament tube and cooling package.

In the upcoming TILS 2016 (4/13~4/16) J0234, POWER PHOTON CO., LTD. will first publish innovative technology of LED filament tube and cooling package.

LED filament with the omni-directional light, high luminous efficiency, high voltage, low current, low glare, etc., strongly guide the decorative lamp market which is quite 40W incandescent light bulb or less. But because of the LED filament’s cooling problem, it’s not available in the biggest cases is quite 60W~100W/ 800lm~1500lm, even quite 150W~200W/ 2200lm ~ 3000lm incandescent light bulb market.

A. Technology, Theory and Specialty;

LED filament is buried in the drying loose material with high thermal conductivity ceramic particles material. The ceramic particles material close contact with LED filament coated surface to decrease the thermal resistance and increase heat conduction. To compare general helium filled LED filament light bulb, it can effective decrease the working temperature 25~30°C ,increase 40% driving current and 35% lighting levels with lower cost and simple manufacturing process. It can achieve 1500 ~ 1800 c.c.t. as the flare which is warmer, soft color temperature and beyond incandescent light bulb’s perfect omni-directional beam pattern.

Same LED filament can be done tube type and cooling package. To compare general helium filled LED filament light bulb, the specialty of LED filament tube and cooling package is:

1. Improve heat dissipation and postpone the life to increase the driving current and the light.

2. Decrease the glare and improve Blue-ray leakage to provide more perfect omni-directional beam pattern.

3. Decrease the color temperature and improve color rendering index.

4. Low material cost, simple manufacture technology, high yield, suitable for mass production.

5. IP54 even IP66 working environment protection level.

6. Small caliber, thick wall, heat-resistant glass lamp, high strength, impact resistance.

7. According to lighting needs 75lm~4800lm, unlimited and high flexible arrangement LED filament tube combination.

In the future, the omni-directional light bulb won’t include PLCC, EMC package or CSP, ELC non-package SMD LED. Of course, there is no MCPCB thermally conductive substrate, heat sink, lamp shade shell and etc. In the successful development of LED filament tube new light source, it towards C.F.L. energy-saving lamps’ divide the work production and sales mode which is the assembly plant procurement filament tube source, power driver module, and etc. production packaging. The brand passage will toward the vast world market for sale.

After more than10 years of accumulated experience of numerous failures, R&D personnel of POWER PHOTON CO., LTD. finally can solve LED filament cooling problem! LED filament tube and cooling package. This patent technology has already applied for registration in many countries of the world. Hope to open a brand new light source solution for human light requirement.

The light source is the market standard specification of LED filament. 45~55V/ 10mA/ 50~55lm 、1.0mm W x 1.8mm H x 38mm L.

Glass tube size is O.D. 6mm and thickness 1.0mm. The length is according to single one LED filament and two、three、four LED filament etc,,…..As following:

Single one LED filament tube, length 50mm, and working power 0.75W/ 75lm.

Two LED filament tube, length 95mm, and working power 1.5W/ 150lm.

Three LED filament tube, length 138mm, and working power 2.25W/ 225lm.

Four LED filament tube, length 170mm, and working power 3W/ 300lm.

The LED filament is known as the omni-directional LED light bar which LED filament light bulb gradually attract the market attention. But in past years, it has been unable to open the market. The main reason is LED filament light bulb cooling problem still needs to be overcome. It makes the price and performance still have a gap with the market expectations.

|

|

Inorganic ceramic materials witch high temperature resistance and high thermal conductivity, for LED there is no bad effect on the chemical incompatibility. In particular, the translucent ceramic material is conducive to the application of LED thermal transmittance.

Dry and loose particulate materials have small friction between the granules and good flow ability. Under appropriate vibration, it tightly packed in the gap between the inner wall of the lamp and light-emitting diode light source. During this period, dry and loose particulate materials bury light-emitting diode light source as the quicksand in the hourglass. The ceramic particulate materials coated the irregular surface of LED filament. The particulate contacts with neighboring particulate, and it has small porosity to reduce the thermal resistance and increase heat conduction.

The ceramic particulate materials on the incident light refraction and diffusion effect can increase the light color rendering index and decrease the color temperature. Meantime, it soft the light to reduce glares and improves the Blue-ray leakage.

LED filament tube and cooling package can improve LED filament 40% driving current and 35% lighting levels because of to reduce the thermal resistance and increase the heat conduction.

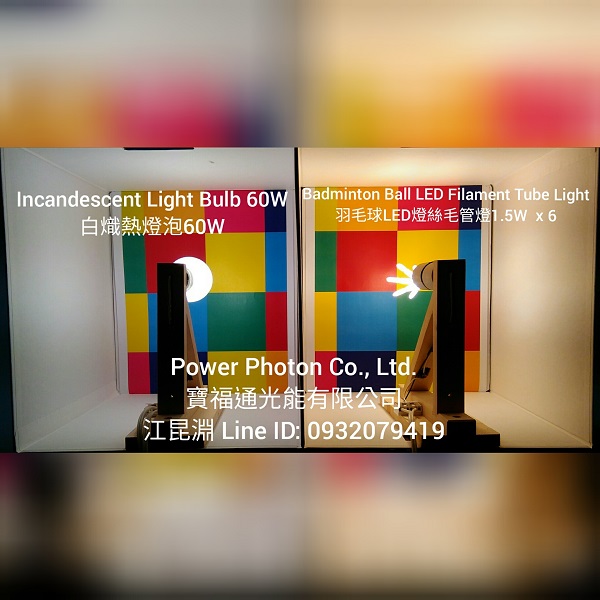

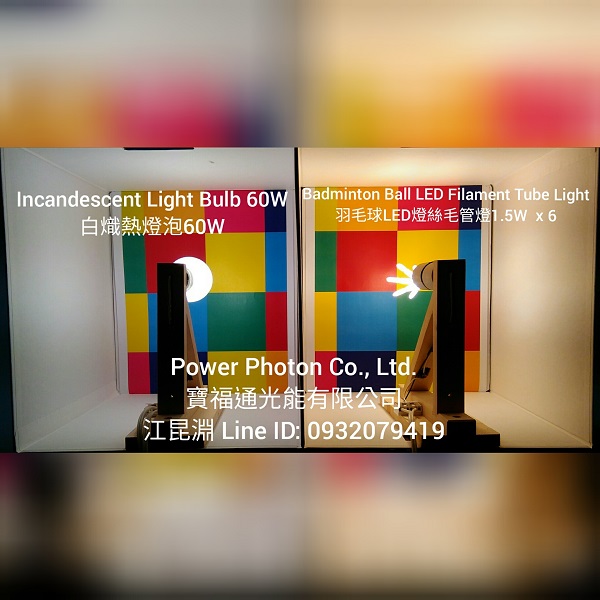

B. 600lm、900lm、1200lm ”Badminton ball” LED tube lamp;

600lm ” Badminton ball” LED tube lamp,4 of 1.5W/ 150lm LED tube combination.

900lm ” Badminton ball” LED tube lamp,6 of 1.5W/ 150lm LED tube combination.

1200lm ” Badminton ball” LED tube lamp,8 of 1.5W/ 150lm LED tube combination.

C. 1800lm、2400lm ”Indian tent” LED tube lamp;

1800lm ” Indian tent” LED tube lamp,6 of 3W/ 300lm LED tube combination.

2400lm ” Indian tent” LED tube lamp,8 of 3W/ 300lm LED tube combination.

D. 3600lm、4800lm ” Sea urchin” LED tube lamp;

3600lm ” Sea urchin” LED tube lamp,24 of 1.5W/ 150lm LED tube combination.

4800lm ” Sea urchin” LED tube lamp,32 of 1.5W/ 150lm LED tube combination.

CN

TW

EN

CN

TW

EN