Until today since the discovery of ultraviolet germicidal effectiveness in 1901, primarily low-pressure mercury lamps have been used for disinfection with ultraviolet.

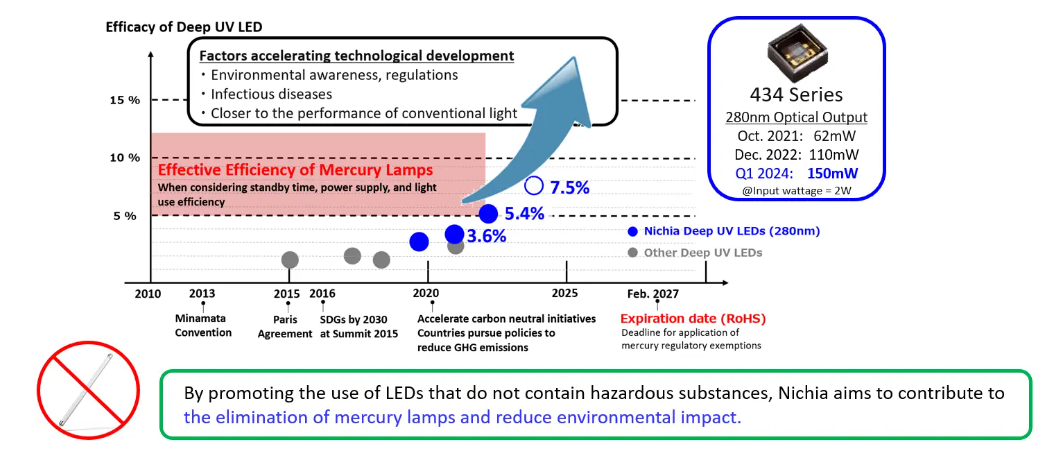

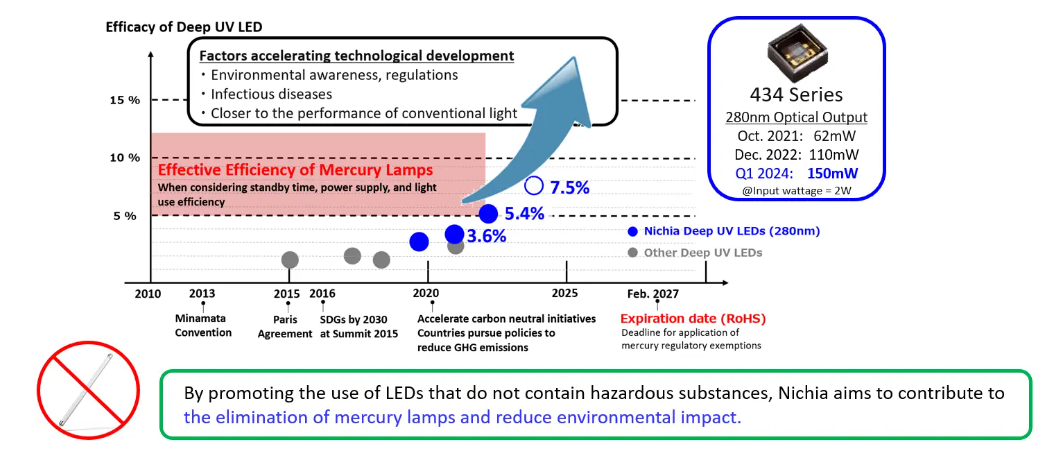

Low-pressure mercury lamps contain mercury and therefore generate concerns regarding environmental pollution. LEDs are expected to be an environmentally friendly alternative technology, similar to the LED replacement of fluorescent lamps. However, although improving year over year at a great rate, the current efficiency of UV LEDs is still less than low-pressure mercury lamps. Thus, the RoHS Directive exempts low-pressure mercury lamps for special applications until February 24, 2027 (Item 4(a)) because no alternative technology has been established. After 2027, this exemption could be extended if it is determined that no alternative technology is available. Is an extension really necessary? Nichia believes that LED adoption is immediately possible for some applications and will be possible in nearly all applications well before February 2027.

Here, Nichia introduces an actual case in which the replacement of low-pressure mercury lamps with UV LEDs is being considered for disinfection applications.

Low-pressure mercury lamps for surface disinfection → LED Adoption Case Studies

The field of ultraviolet disinfection using low-pressure mercury lamps includes water and sewage system disinfection, air disinfection via purifiers, and surface disinfection. One typical example of surface disinfection is the disinfection of containers and equipment in the food industry. In food manufacturing plants, containers are filled with food after being irradiated with ultraviolet to disinfect the inside of the containers to prevent contamination and growth of bacteria in the food.

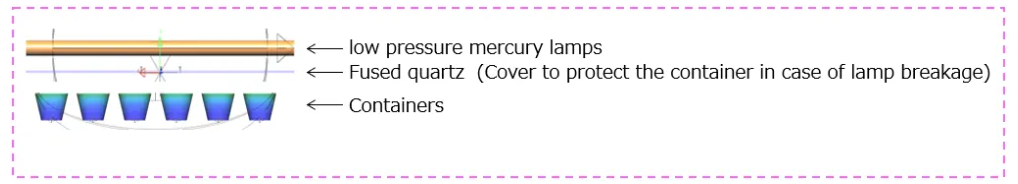

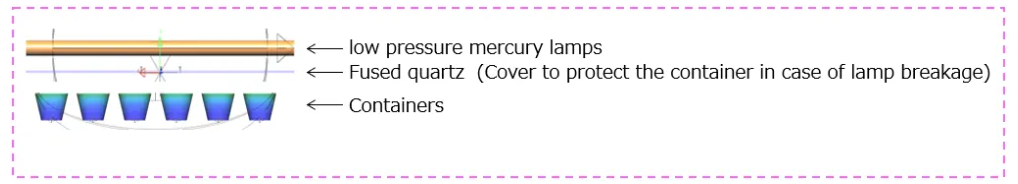

Image of UV irradiation of food containers:

To disinfect multiple food containers at once, ultraviolet are irradiated from above the containers by low-pressure mercury lamps to disinfect the inside of the containers. At that time, low-pressure mercury lamps must be covered with fused quartz to avoid contamination of the mercury and broken glass in case the lamp breaks.

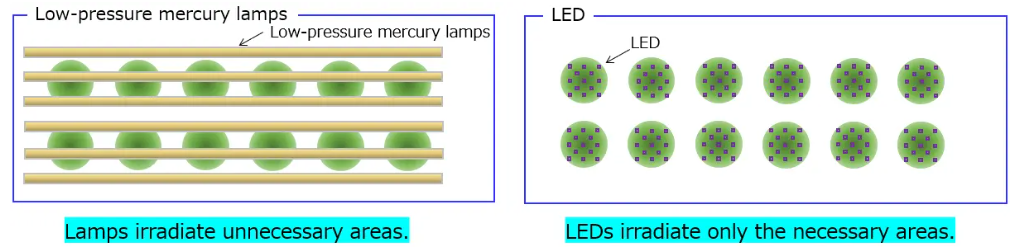

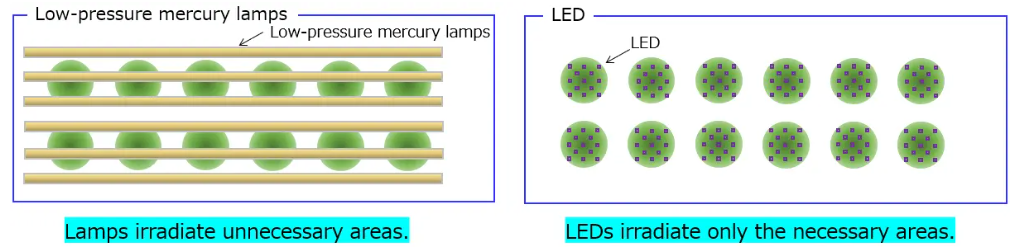

Image of irradiation viewed from above:

As shown in the irradiation image above, unlike low-pressure mercury lamps, LEDs can be used to irradiate only the target object with ultraviolet because the configurations and locations can be precisely adjusted and selected. Low-pressure mercury lamps, on the other hand, irradiate in all directions, so that the gaps between individual containers and the back of the lamps are also exposed to unnecessary ultraviolet radiation.

In addition, low-pressure mercury lamps must remain "on" constantly during operation as they take significant time to turn on and off. Whereas LEDs allow instantaneous on/off, so they can be turned on only when necessary, which can contribute to the reduction of the energy consumption and CO2 emission.

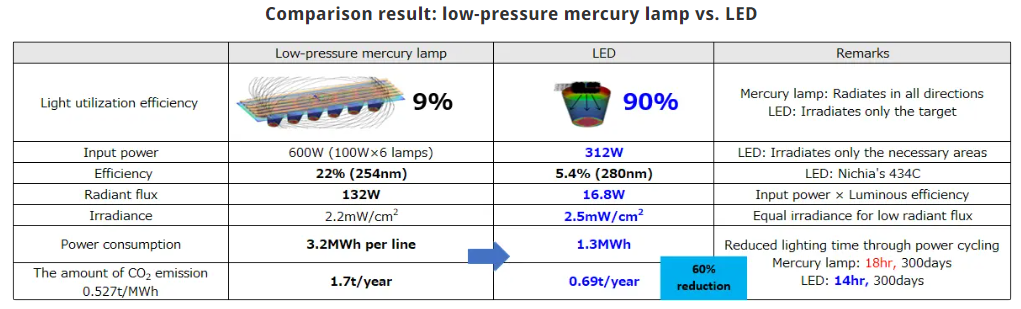

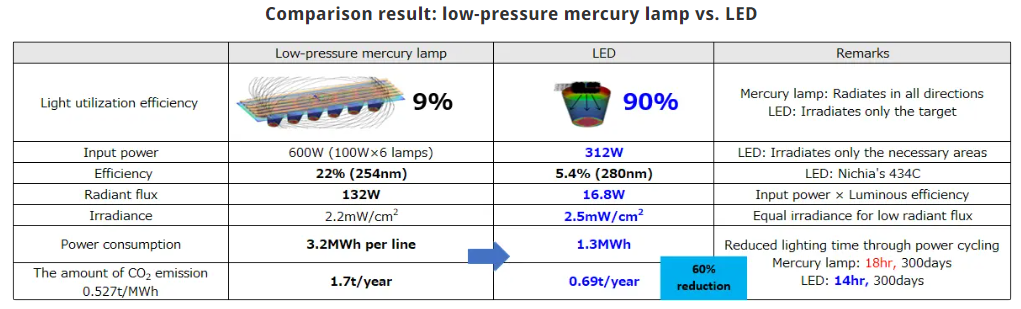

Considering the above details, the following table shows the results of a comparison between low-pressure mercury lamps and LEDs.

Study result

-

The input power of 600W and 312W is the input power required to achieve the same disinfection effect in the actual values in this study example.

-

The LED efficiency and irradiance were based on Nichia's measurement using Nichia's UV LED 434C.

-

CO2 emissions of 0.527t/MWh is the CO2 emission factor for FY2021 announced by Shikoku Electric Power CO., Inc.

The efficiency of low-pressure mercury lamps is 22%, which is higher than that of LEDs at 5.4%. However, while low-pressure mercury lamps utilize only 9% of the UV irradiation they emit, LEDs can utilize as much as 90%. Therefore, the power input required to achieve the same disinfection effect is significantly reduced from 600W for low-pressure mercury lamps to 312W for LEDs. In addition, LEDs can be turned on only when necessary, so in this case, where low-pressure mercury lamps are turned on for 18 hours a day, LEDs can be turned on for 14 hours a day, and assuming that they are operated for 300 days each, the power consumption of low-pressure mercury lamps with 600W of input power is 3.2MWh per year, while LEDs with 312W of input power consume 1.3MWh per year, a 60% reduction. CO2 emissions are also calculated based on CO2 emissions of 0.527 tons per 1 MWh of electricity consumption. Low-pressure mercury lamps emit 1.7 tons of CO2 per year, while LEDs emit 0.69 tons, also a 60% reduction.

Roadmap

Summary

In this case study, the features of LEDs, such as high radiant flux utilization through selectively illuminating only the necessary areas and reduced on time through instantaneous on/off capabilities, were utilized to achieve significant benefits. Thus, Nichia can clearly demonstrate that LEDs can be an alternative technology to low-pressure mercury lamps.

In addition to the above example, Nichia will also work with its customers and partners to develop designs that take advantage of LED features in other disinfection applications, including water and air disinfection. Nichia will try to realize the adoption of LED technology over low-pressure mercury lamps as much as possible.

Furthermore, as indicated in the roadmap, the performance of UV LEDs has shown remarkable improvement in recent years. The synergistic effect of development expectations for LEDs arising from environmental regulations and the need to combat infectious diseases is accelerating technological development. By developing a design that takes advantage of LED features, the adoption of LEDs over low-pressure mercury lamps is already being realized in some cases. Nichia believes that this, combined with the remarkable improvement in the basic performance of UV LEDs, will lead to an even greater trend, and UV LEDs will be naturally recognized as an alternative to low-pressure mercury lamps in all disinfection applications and fields. As a result, the extension of the RoHS exemption beyond 2027 will no longer be necessary.

Nichia will continue to improve the performance of LEDs and make an effort to solve social issues such as the realization of a mercury-free and carbon neutral society.

TrendForce 2024 Deep UV LED Market Trend and Product Analysis

Release: 31 March, 30 September 2024

Language: Traditional Chinese / English

Format: PDF / EXCEL

Page: 50-60 / Semi-Annual

If you would like to know more details , please contact:

CN

TW

EN

CN

TW

EN