-By Chih Chieh Huang, Lighting Designer, Sep, 2011

In recent years, the LED light source has dramatically changed the lighting industry, adding numerous possibilities in lighting and it is expected both by the industry and the household users to completely replace the traditional light source as a brand new light solution in the near future.

As a rapidly growing sector, LED lighting has evolved from only RGB LED about six or seven years ago to white LED architectural lighting in recent years. Despite the ongoing emergence of new LED technologies and lighting products, we still have doubts about whether it is time to embrace the LED technology: Is LED lighting ready to be used as general lighting? Can these products which were developed recently meet the needs of end users (designers and consumers)? Have LED manufacturers taken the need of the end user (architect/designer/consumer) into account during the R&D or design process? Is there a gap between the claimed product performance by LED manufacturer and the actual needs of the designer? At this stage, the focus is always on what degree of technology can be achieved. However, shouldn’t “end user’ be central to the design concept?

After all, it is people who think and create. Science and technology are just a means to help realize people’s dreams. In this article, we will view LED development and the designer’s needs when applying LED light source from the perspective of architectural lighting design. Moreover, the win-win situation can only be achieved through ongoing communication and cooperation between manufacturers and designers, combining technology and practicality.

-

-

Photo Credit: John Pawson

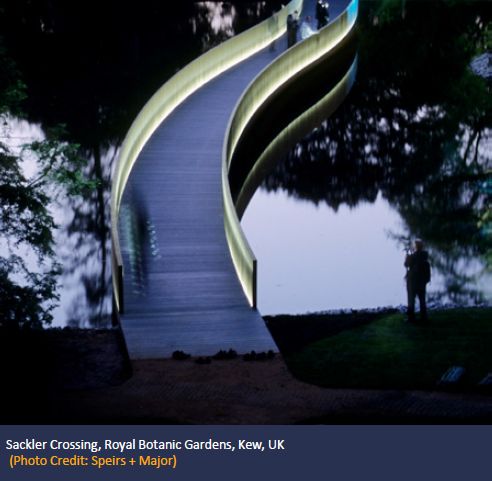

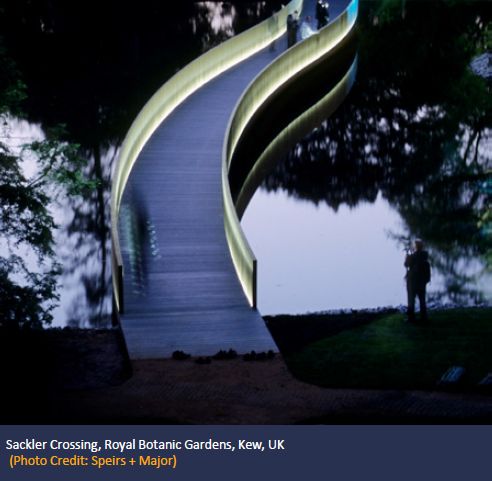

First, we will take a look at the current situation and some cases of LED utilization in architectural lighting. Although there are precedents of LED street lighting application, there were only a few cases, and the effect still remains to be assessed. Generally speaking, LED is not fully ready to be adopted as general lighting or as major light source. It is mostly applied in partial lighting and feature lighting, like wall washing, back-lighting, bridge lighting (Sackler Crossing/ Bridge of Aspiration), or in the case of strong dynamic effect needed for building facade (Talee Star Place, Kaohsiung)

Quality of light is the major concern for the lighting designer when deciding whether to use LED.

-

-

Photo Credit: John Pawson

What is quality of light?

Consistency

Consistency refers to whether the color temperature of the light source is consistent, especially when two light sources are compared with each other. It usually involves the use of binned LED. In general, a lighting product will be more stable if double binning system is used by the manufacturer, which is critical for architectural lighting. It will become an obvious mistake in its design if two adjacent LED wall washers show visible differences in color temperature. Consistency also refers to stability over time, including whether luminous decay or color temperature will differ after a period of use.

Color rendering

Many alleged high CRI LED products have been put on shelves, but a designer should pay attention to whether high CRI really means excellent CRI. For example, in places such as museums or galleries where the lit objects require precise color rendering, we usually ask manufacturers for LED SPD (Spectral Power Distribution). The lit objects will be presented in unnatural colors if the wavelength is discontinuous, for which end users have expressed that many types of LEDs on the market make lit objects, especially faces or bodies, look ‘odd’.

Quality of light discussed above refers to the light source, while in application, it refers to whether LED light fixture can meet various functional needs, for example, spotlight, floodlight, downlight, uplight, wall washer, and light for high ceilings.

Efficiency

In terms of efficiency, high power LED has far surpassed that of conventional incandescent lamp and some have even exceeded the efficiency of fluorescent tube. However, the efficiency of LED street lighting still has cannot match that of the

metal halide lamp. Furthermore, LED light efficiency decay often occurs under high temperature and high drive current.

Control

Complex adjustments can be achieved in light control.

Cost

Cost of LED lighting is still too high but it is expected to reduce to an affordable level for the general public in the future.

Reliability & Maintenance

As discussed above, LED efficacy declines and its lifetime shortens due to high operation temperature and unstable current, which will reduce its reliability.

Therefore, we should ask whether the manufacturer will provide a warranty period and the maximum operation temperature for the fixtures at which the quoted lumen maintenance is achieved. If LED light shows difference in color temperature or burns

out during the warranty period, what is the strategy of the manufacturer?

Will they provide any maintenance services? To our knowledge, many manufacturers fail to meet expectations in this aspect. Moreover, most LED fixtures are permanent devices, especially in the architectural lighting, so reliability and maintenance is an important issue.

In this fast changing industry, lighting designers are often caught in this situation: an advanced LED solution is designed for a project set to be completed two years later. The potential danger lies in that the higher the expectation, the greater the disappointment.

In spite of the aforementioned concerns, we still hold high expectations and believe that within the next two to three years, LED light sources will replace the traditional light source in general lighting and even become the main light source, and become the major light source in commercial

spaces, such as hypermarket, halls of 4~5m in height, or airport lighting with 24-hour operation.

-

-

Photo Credit: John Pawson

How do we achieve the goal?

At present, LED industry has started to develop a type of LED lamp where LED is built into the fixture shell, aiming to directly replace the conventional tungsten bulb and fluorescent tube. It seems to have increased convenience and reduced the cost of replacing fixtures, making it possible for consumers to buy LED lamps to directly replace the existing one. However, in fact, it is not a lamp because the actual lamp is hidden inside the lighting fixture. In my opinion, although the industry tries to work out the easiest replacement solution for consumers, the wrong direction is adopted.

As the design of the existing fixture is not based on the optical properties of an LED, optimal efficiency cannot be achieved by a direct replacement, neither can visual comfort or light effect originally designed for the lamp be achieved through this replacement.

We should develop a new system, a new size and a new lighting fixture based specifically on LED properties. The success of development hinges on the close operation and the frequent dialogue bet ween designers and manufacturers; this is necessary to develop a product of both aesthetic and practical value.

The next step for manufacturers is to normalize, standardize and mass produce products. Meanwhile, the product pgradability should also be considered. As mentioned earlier, LED industry is evolving rapidly, hence, it will be cost effective if the LED module is upgradable without having to replace the whole lighting fixture when the original LED lamp needs to be replaced in 5 to 10 years later.

CN

TW

EN

CN

TW

EN