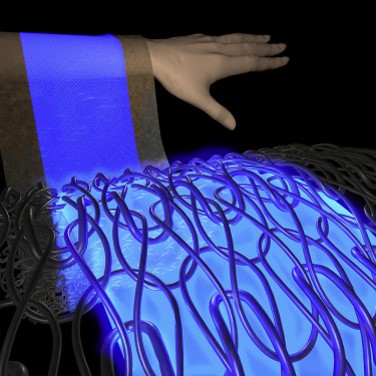

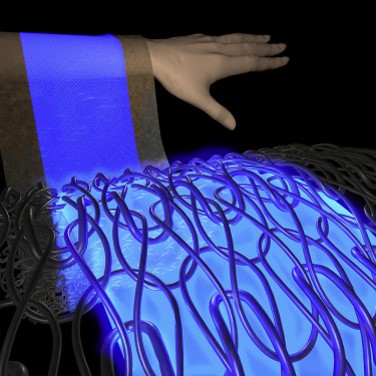

A new type of light emitting textile may enable innovative wearable applications. Researchers at the University of Windsor in Canada published their development in the journal Matters, revealing a stretchable, lighting emitting fabric based on typical ultrasheer pantyhose coated in a thin gold film.

(Image: Matters)

The new development tackled some of the limitations of existing light-emitting fabrics and use the textile structure as an integral part of the wearable device design. With effective power sources, the light emitting fabric could be further developed into more functional designs for safety gear worn by first responders and nighttime construction workers, light-emitting athletic apparel, avante garde and everyday fashion, or wearable advertisements and logos.

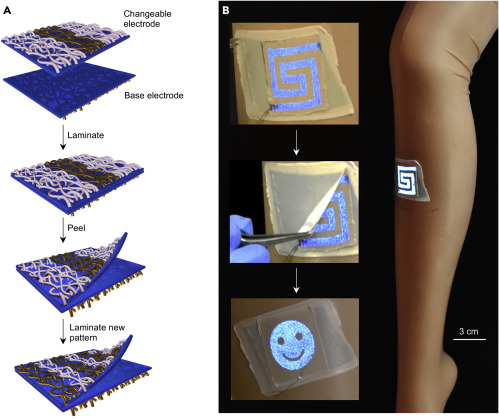

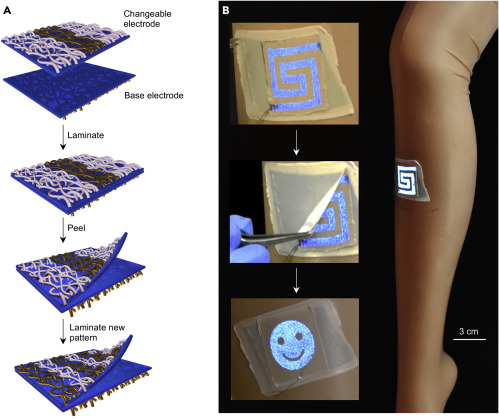

The researchers used electroless nickel-immersion gold metallization, a solution-based metal-deposition technique often used to make printed circuit boards that only deposits metal on the nylon and spandex fiber surfaces, to coat pantyhose with a highly conductive gold film only about 100 nm in thickness. They found that the coating process allowed the pantyhose fabric to retain its semi-transparency and stretchiness. Using this new fabrication technique, the researchers next created patterned light-emitting textiles with the smiley-face emoji, as well as a dynamic display comprised of seven rectangular segments that can rearrange to display numbers zero through nine.

(Image: Matters)

"We are optimistic about the ability to scale up the technology," said Tricia Carmichael, a professor of surface and materials chemistry at the University of Windsor. "The process we use to deposit the ultrathin gold coating on fabric fibers can be scaled up by increasing the volume of the plating solution, enabling processing of entire articles of clothing. We also use existing ultrasheer fabrics and thus do not require new textile manufacturing."

Nevertheless, the technology still need to be powered without bulky energy generators and storage systems to make integrated wearable light emitting devices feasible in daily life.

"We are exploring the wide variety of textile architectures as an integral part of device electrode design to enable the seamless integration of brittle energy storage materials into textiles," says Carmichael.

CN

TW

EN

CN

TW

EN