Micro LED technology developers from Taiwan unveiled their latest progress in quantum dots (QD) color conversion and wafer production. Lextar introduced its progresses in reliable QD development to realize full color Micro LED displays while PlayNitride shared its achievement of 6-inch Micro LED epitaxial wafers with advanced uniformity.

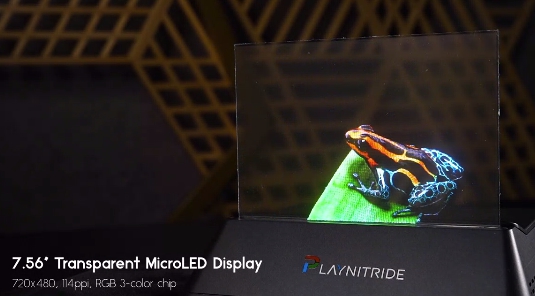

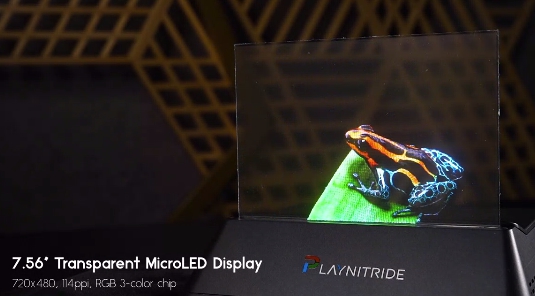

(Image: screenshot from PlayNitride video)

Lextar, a vertical integrated LED company based in Taiwan, shared that the company has been working on deploying QD color conversion technology on Micro LED display. Since Micro LED is too small to combine with phosphor, using QD is a more feasible approach to develop full color Micro LEDs. However, since QDs are very small in size, they are fragile and uneasy to apply as well. After focusing on QD for more than 10 years, the R&D team of Lextar has overcome the challenges and built QD in package for Micro LED displays. Lextar also noted that using Micro LED with shorter wavelengths can further improve the efficiency of QD.

Lextar and Epistar have set up a new holding company ENNOSTAR to advance their development in Micro/Mini LED as well as in VCSEL and other sensing and data transmitting technologies. The two companies aim to avoid double investment and research on these projects and to focus on their expertise through the partnership. Lextar will address in packaging and modular solutions while Epistar will concentrate in wafer and chip processing.

On the other hand, Micro LED company PlayNitride revealed its progress in Micro LED wafer production. It has achieved the mass production standard of uniformity with its 6-inch Micro LED wafer production. Charles Li, PlayNitride CEO, noted that combining its mass repair solution and the wafer with advanced uniformity, Micro LED displays are in the last phase to volume production.

The company developed a solution to integrate 16 RGB Micro LEDs on a PCB substrate, named PixeLED Matrix. Based on the approach, PlayNitride aims to further reduce production for Micro LED display production.

CN

TW

EN

CN

TW

EN