In order to improve the efficiency and lighting quality of LEDs, metal halide perovskites have been considered as a next generation material. Perovskite LEDs (PeLEDs) as emerging light-emitting technology have attracted attentions with the advantages of low manufacturing cost, high light quality and energy efficiency. A research co-led by the scientists from City University of Hong Kong (CityU) and Shanghai University developed a new manufacturing process to enhance optical properties and stability of perovskite LEDs.

The research team used cesium trifluoroacetate (TFA) as the cesium source in the one-step solution coating to enable fast crystallization of small-grained CsPbBr3 perovskite crystals, which then forms a smooth and pinhole-free perovskite films. With the film added, researchers developed green PeLEDs with a maximum current efficient of 32.0 cd A-1 corresponding to an external quantum efficiency of 10.5% in comparison to current existing PeLEDs. In addition, PeLEDs based on the films demonstrated 17 times longer operational lifetime.

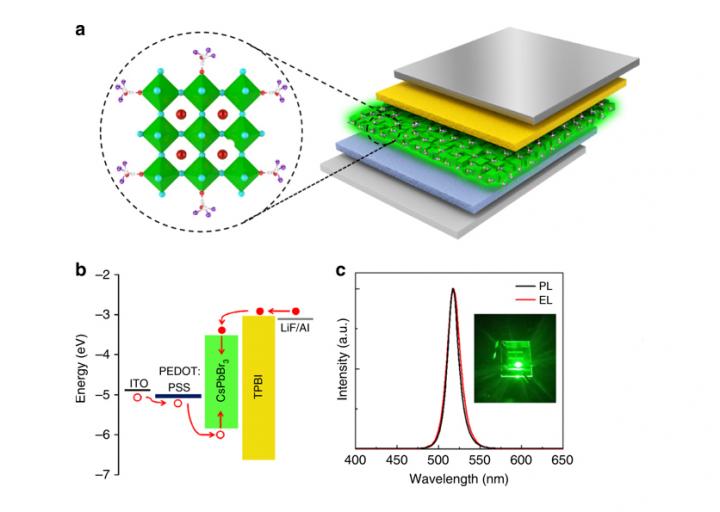

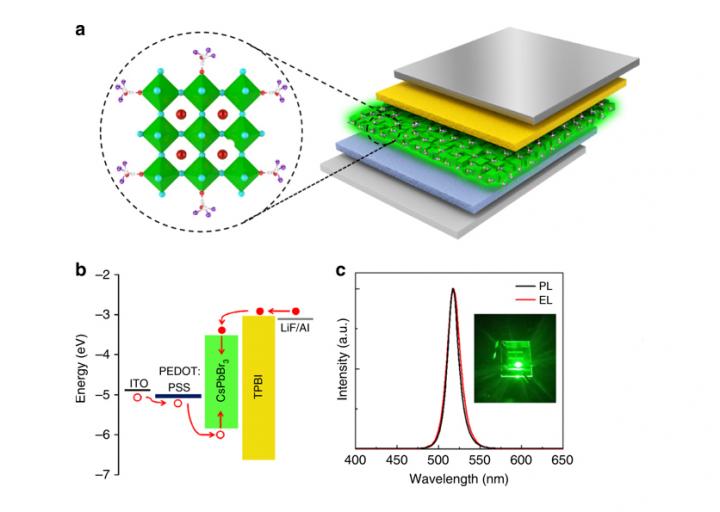

a) Device structure and a corresponding cross-sectional TEM image of the multi-layer PeLEDs

b) Schematic flat-band energy diagram of the PeLED

c) Normalized photoluminescence spectrum of the CsPbBr3 film, and electroluminescence spectrum of the PeLED at an applied voltage of 5.5 V

(image: City University of Hong Kong)

"Our study suggests that the high color-purity and low-cost all-inorganic lead halide perovskite films can be developed into highly efficient and stable LEDs via a simple optimization of the grain boundaries," says Andrey Rogach, Chair Professor of Photonics Materials at CityU.

The research result was published in Nature Communication, titled "Trifluoroacetate induced small-grained CsPbBr3 perovskite films result in efficient and stable light-emitting devices ".