Researchers have designed a new LED-based train headlight that uses a tenth of the energy required for headlights using conventional light sources. If operated 8 hours every day, the electricity savings of the new design would reduce emissions of the greenhouse gas carbon dioxide by about 152 kilograms per year.

Researchers led by Guo-Dung J. Su from the Micro Optics Device Laboratory of the Graduate Institute of Photonics and Optoelectronics at National Taiwan University, Taiwan, and the engineering and design company Lab H2 Inc., to design locomotive headlights that use LEDs as a light source. In addition to requiring less energy, LEDs also last longer and are smaller and more rugged than traditional light sources.

"Some LED headlight products sold on the market are designed with many LEDs that have outputs that overlap in large sections. These designs waste a lot of energy," said Wei-Lun Liang of the Micro Optics Device Laboratory, who was instrumental in designing the new train headlight. "Our research showed that electricity use can be reduced by focusing on the best way to distribute the LED energy equally."

In The Optical Society journal Applied Optics, Liang and Su report a new train headlight design based on ten precisely positioned high efficiency LEDs. The design uses a total of 20.18 Watts to accomplish the same light intensity as an incandescent or halogen lamp that uses several hundred watts. The new headlight can also be dimmed by turning off some of the LEDs to avoid blinding waiting passengers when the train passes a platform, for example.

|

|

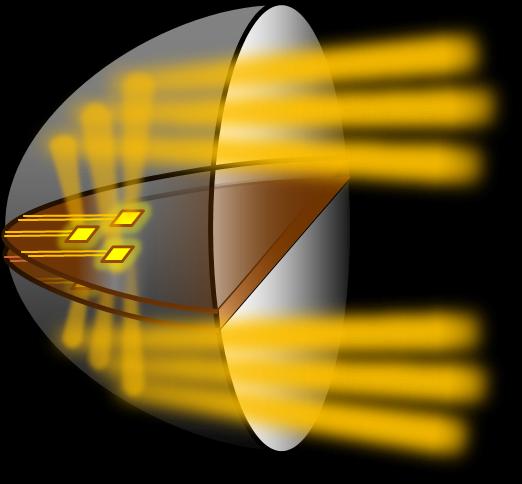

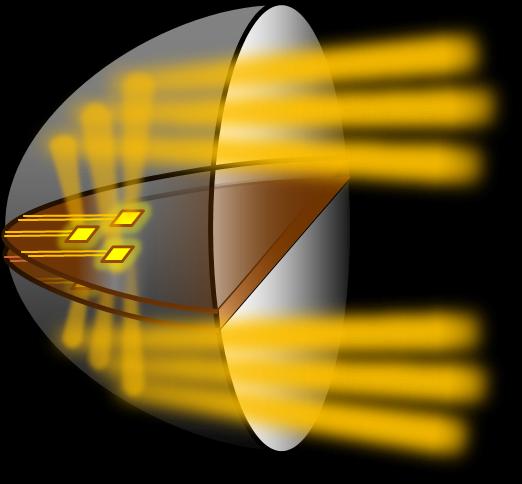

A new train headlight design uses two half-circular parabolic, or cup-shaped, aluminized reflectors with high-efficiency LEDs placed in the plane where the two reflectors come together. Combining the strong beams from each reflector generates the light intensity necessary to meet safety guidelines. (Image: Wei-Lun Liang, National Taiwan University) |

Designing for energy efficiency

Much like those used for cars, train headlights typically combine a light source with a parabolic, or cup-shaped, reflective surface that focuses the emitted light into a beam. Although LEDs are a great option for saving energy, the most energy-efficient LEDs emit smaller spots of light. For this reason, the researchers had to combine the small outputs of multiple high-efficiency LEDs into a larger circular output to create a beam large enough to use as a train headlight.

"Combining several LEDs is more expensive and consumes more electricity than using a few single LEDs," said Liang. "Thus, we needed to determine how to best position the lowest possible number of high-efficiency LEDs needed to meet the requirements by analyzing how the parabolic surface reflected the LED lights."

The researchers' goal was a headlight that would provide light 1.25 times the brightness required by U.S. federal regulations. These regulations require train headlights to have a peak intensity of at least 200,000 candelas and illuminate a person at least 800 feet in front of the headlight.

Positioning the LEDs to save energy and meet federal guidelines came with several challenges. The researchers had to be careful to overlap the LED outputs just enough to create a large beam, but not so much that more LEDs, and thus more energy, would be needed. Also, the LEDs must be placed far enough from each other for heat to dissipate to prevent circuit damage.

Positioning the LEDS To create a high-efficiency train headlight, the researchers used two half-circular parabolic aluminized reflectors. When used together, the strong beams from each reflector combine to generate the light intensity necessary to meet federal guidelines. This design also simplified placement of the circuits needed to power the LEDs because they could be housed in the horizontal divider separating the reflectors.

To determine where to place the LEDs in the reflectors, the researchers first estimated the best location of each LED and then used a series of tests and simulations to fine-tune the final position for each LED based on its corresponding illumination pattern. "Other scientists can use the linear equation we derived for deciding the approximate positions of LEDs for other applications," said Liang. "This can substantially shorten the time required to determine LED positioning before fine-tuning the positions."

The researchers point out that headlights typically use a complete parabolic reflector surface. "We believe this is the first design to use a combination of two semi-parabolic reflector surfaces," said Liang. "By systematically analyzing the design to determine the best placement of the LEDs in the reflector, we were able to minimize electricity consumption while satisfying requirements associated with traffic safety."

The researchers are now working to turn their design into a commercial product. Even though the new design exhibits low power consumption, it still generates some waste heat. Before the design can be commercialized the researchers will need to develop and test a heat dissipation system for the new headlight.

CN

TW

EN

CN

TW

EN