New composite material to prevent cracks in semiconductor layers

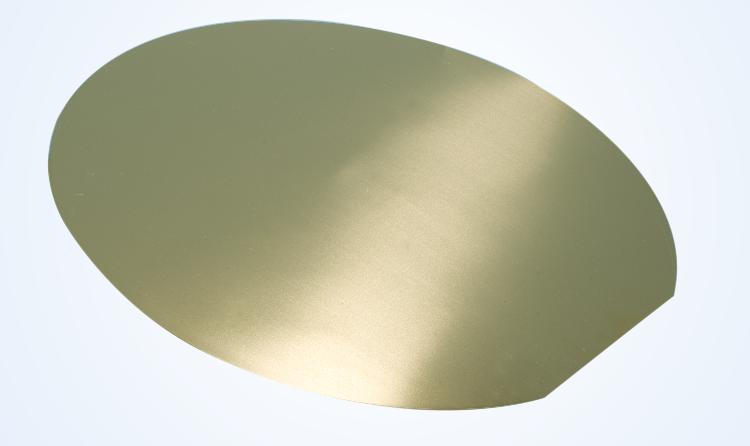

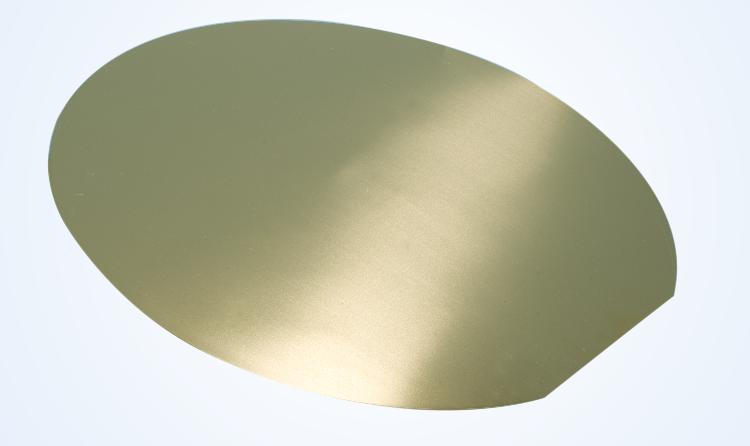

With Mo-Cu R670, “PLANSEE High Performance Materials” has developed a new molybdenum-copper composite material for semiconductor wafer substrates. The high thermal conductivity of MoCu R670 ensures optimized heat dissipation in LED chips. The new material has the same coefficient of thermal expansion as sapphire, andtherefore reducesdefects in the semiconductor structure which can occur during the hot bonding process.In this way, Mo-Cu R670 helps ensure the reliable production of LED chips and increases the efficiency of the light source.

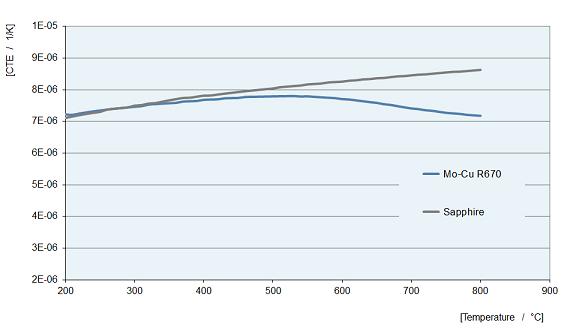

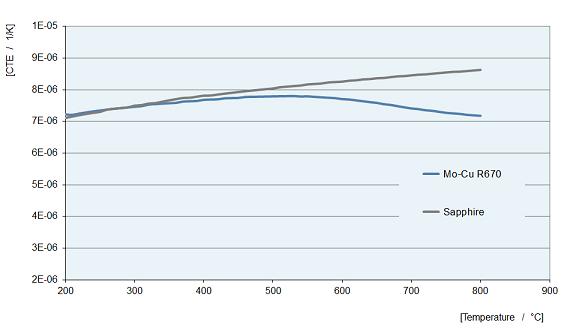

In the most commonly used process for the production of blue spectrum chips- including white LEDs -gallium nitride-based semiconductor layers (GaN) are grown on sapphire substrate (Al2O3) using epitaxial growth methods like MOCVD. A metallic wafer, intended for the dissipation of heat, is then bonded to the semiconductor layers at high temperatures using various joining technologies. Stresses caused by different coefficients of thermal expansion can lead to cracks in the semiconductor layers. To prevent these defects, the metal wafersubstrate ideally possesses the same coefficient of thermal expansion (CTE) as sapphire.

Molybdenum is commonly used for suchwafer substrates. This material offers good thermal conductivity and is very heat-resistant. However, molybdenum has a lower coefficient of thermal expansion than sapphire (Al2O3). That’s why PLANSEE developed wafer substrates made from the molybdenum-copper composite material R670 especially for sapphire-based and high temperature-bonded LED chips. R670 has a thermal conductivity of 170 W/mK and, with 6.7 ppm/K, the same coefficient of thermal expansion as sapphire (Al2O3).

PLANSEE can supply Mo-Cu wafer substrates with coatings made from nickel-gold, ruthenium, chromium, silver and other interface materials. These coatings protect the wafer substrate against corrosion and optimize its surface properties for the subsequent bonding process.

As one of the world's leading manufacturers of refractory metals and composite materials, PLANSEE supplies metallic wafer substrates for heat dissipationand also numerous other components for the production of LED chips and LED packages. These include furnace components and molybdenum and tungsten crucibles for sapphire single crystalgrowth, components for MOCVD/MBE reactors, evaporationboats and coils for metallic mirror or barrierlayers and base platesfor improved thermal managementof high-power LEDs.

CN

TW

EN

CN

TW

EN